Ribbon mortar dry powder mixer is a device specially used for preparing and mixing ribbon dry powder mortar. Ribbon dry mortar is a high-performance, high-strength construction mortar that is widely used in wall masonry, floor paving and other projects. The following will introduce the working principle, characteristics and usage precautions of the spiral belt dry mortar mixer.

The Ribbon Dry Mortar Mixer plays a key role in the production of dry mortar and has many important applications:

Raw material mixing: Cement, sand, lime, additives and other raw materials are put into the mixer according to precise proportions. Its ribbon structure allows materials of different particle sizes and densities to fully tumble and convect in the mixing drum, and quickly achieve uniform mixing.

Additive dispersion: Functional additives such as cellulose ether and redispersible latex powder are often added to dry mortar. The strong stirring effect of the ribbon mixer can evenly disperse these additives in a large amount of materials, so that they can fully retain water, increase viscosity and improve construction performance.

Premixing function: In some large-scale dry mortar production lines, the ribbon mixer can perform premixing. First, some of the main raw materials are preliminarily mixed and then transported to the subsequent more sophisticated mixing process.

Special formula mixing: For dry mortars with special formula requirements, such as waterproof dry mortar and self-leveling dry mortar, the ribbon mixer can accurately mix various raw materials with excellent stirring effect to meet special performance requirements.

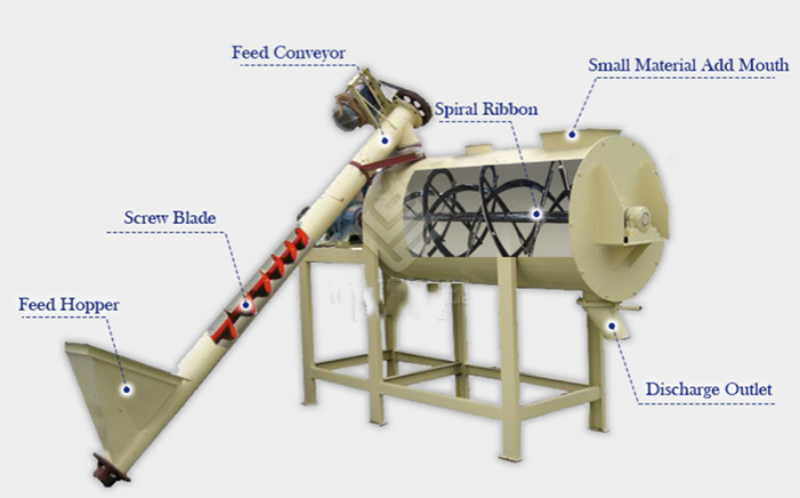

The ribbon mortar dry powder mixer mixes the dry powder mortar raw materials through the rotating ribbon mixing device. The ribbon mixing device consists of one or more spiral stirring blades. It stirs, grabs and turns the mortar raw materials through rotation to achieve uniform mixing of the raw materials.

Efficient mixing: The ribbon mixing device can fully mix the mortar raw materials to ensure the uniform distribution of various ingredients and improve the quality and stability of the mortar.

Good uniformity: The mixing blades of the ribbon mixing device are reasonably designed to achieve high-speed, uniform mixing effects and avoid local accumulation and agglomeration of raw materials.

Automated operation: Ribbon mortar dry powder mixers are usually equipped with advanced automatic control systems, which can realize automated mixing processes, reduce manual operations, and improve production efficiency and operational convenience.

Durable and reliable: The ribbon mixing device adopts high-strength materials and precision manufacturing processes, has good wear resistance and corrosion resistance, and can operate stably for a long time, reducing maintenance and replacement costs.

Versatility: Ribbon mortar dry powder mixers usually have a variety of mixing modes and accessory options, which can be adapted to different types and proportions of ribbon dry powder mortars to meet various construction needs and can be customized according to customer requirements.

| Model | LHY-0.25 | LHY-0.5 | LHY-1 | LHY-1.5 | LHY-2 | LHY-3 | LHY-4 | LHY-6 | LHY-8 | LHY-10 |

| One-time mixing (kg) | 100-150 | 200-300 | 400-600 | 600-900 | 800-1000 | 1200-1800 | 1600-2400 | 2400-3600 | 3200-4800 | 4000-6000 |

| Mixing time (min) | 8-20 | 8-20 | 8-20 | 8-20 | 8-20 | 8-20 | 8-20 | 8-20 | 8-20 | 8-20 |

| Mixing speed (r/min) | 60 | 55 | 45 | 40 | 35 | 25 | 25 | 20 | 15 | 15 |

| Motor power (kw) | 3-5.5 | 4-11 | 7.5-15 | 11-18.5 | 15-22 | 18.5-30 | 22-37 | 37-55 | 37-55 | 45-75 |

| Weight (kg) | 500 | 900 | 1800 | 2500 | 3200 | 4100 | 5100 | 6300 | 7500 |

The ribbon dry mortar mixer has the following main functions when mixing materials.

Prevent dry mortar from agglomerating and caking: During the mixing process, the rotation of the ribbon can produce continuous shear force and dispersion force on the material, effectively breaking up the agglomerates and lumps between the materials. Especially for some materials that are easy to absorb moisture or have high viscosity.

Less damage to dry mortar: Compared with some high-speed rotating or strongly impacting mixing equipment, the ribbon mixer causes less damage to the material particles during the mixing process. This can better maintain the original physical properties and structure of some dry mortar materials that require high particle integrity.

Adapt to different materials: For materials with different particle sizes, shapes and fluidities, the ribbon dry mortar mixer can mix and mix well.

Maintain dry mortar characteristics: Through a reasonable mixing process, the ribbon mixer can maintain the characteristics and performance of the raw materials to ensure that the mixed dry mortar meets the requirements.

Ribbon dry mortar mixer is the core equipment in dry mortar production, and its selection is directly related to production efficiency, product quality and operating costs. The following is a detailed guide to choosing the right equipment:

Production scale

Small batch production: Choose an intermittent mixer with a small capacity (such as 0.5-2 cubic meters).

Large-scale production: Prefer continuous mixers or large-capacity equipment (such as 3-10 cubic meters) to meet continuous feeding needs.

Material characteristics

Ingredient diversity: If you need to mix multiple raw materials (such as cement, sand, additives, etc.), you need to ensure that the equipment can evenly disperse materials of different densities.

Particle fineness: Fine powders (such as gypsum powder) need to choose equipment with good sealing and adjustable mixing speed to avoid dust.

Viscosity requirements: High-viscosity materials (such as mortar containing polymers) need to be equipped with a strong drive system to prevent material adhesion.

Finished product requirements

Mixing uniformity: For products with high uniformity requirements (such as self-leveling mortar), you need to choose equipment with optimized ribbon design and controllable mixing time.

Special functions: If you need to add liquid ingredients (such as emulsions), you need to choose a mixer that supports a liquid spray system.

Equipment capacity: Select the capacity according to the hourly production requirements (such as 1-5 tons/hour).

Industry application adaptation

Ordinary dry mortar: Choose a standard ribbon mixer, focusing on cost-effectiveness and durability.

Special mortar (such as insulation, waterproofing): A high-precision mixing system is required to ensure that lightweight aggregates (perlite) or additives are evenly dispersed.

Operators should operate the spiral belt dry mortar mixer correctly in accordance with the equipment instructions to ensure safety and normal operation.

Before use, check whether all parts of the mixer are intact and ensure that the equipment is functioning properly.

According to the formula requirements of spiral belt dry mortar, accurately measure and add raw materials, and follow the proportions.

When adding water, control the amount gradually to prevent the mortar from being too thin or too dry.

The mixing time depends on the specific situation. Generally, it needs to be stirred for 2-5 minutes to ensure that the mortar is fully mixed.

During the mixing process, the machine can be stopped in time to check the uniformity and moistness of the mortar. If necessary, the amount of water can be adjusted or mixing can be continued.

When using the mixed spiral ribbon dry mortar, pay attention to control the dosage and construction speed to prevent the mortar from drying out prematurely or losing its plasticity during the construction process.

Through the use of spiral belt mortar dry powder mixer, efficient, uniform and stable spiral belt dry powder mortar mixing can be achieved, improving construction efficiency and mortar quality. In actual operation, appropriate adjustments and improvements should be made based on specific conditions and experience to obtain the best construction results.

In the field of dry mortar mixing equipment, Dahan Machinery has established a good reputation with its excellent quality and affordable prices. We have focused on the research and development, production and sales of ribbon mixers for many years and have accumulated rich industry experience. In terms of price, we always adhere to the concept of creating the greatest value for customers. Because we have our own independent modern production workshop, from raw material procurement to product assembly, we strictly control costs in every link, so we can provide customers with cost-effective ribbon mixers. Compared with similar products on the market, our equipment is reasonably priced and transparent, with no hidden costs. If you need it, please contact me for a quote.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.