Can mix powdery, granular and liquid materials of different densities, different particle sizes and different properties

![]()

![]()

Price:$3,800.00-$25,000.00/Set

Consult now and enjoy a 10% discount

Mixing time: 5-10min

Range of Spindle Speed(r.p.m): 44 - 175 r.p.m

Capacity: 400-12000kg

Voltage: 220V/380V/customize

Power: 4-37kw

Application materials: powder coatings, rubber products, plastic granules, fertilizers, pigments and pigment powders, powder additives, pharmaceutical powders, tablets and capsule raw materials, traditional Chinese medicine powders, food additives, food seasonings, food granules, food dry mixes, coffee powder and Tea mixture, pesticide granules, pesticide additives, pesticide powder, cement, gypsum, lime and other powders, ores, mineral powder.

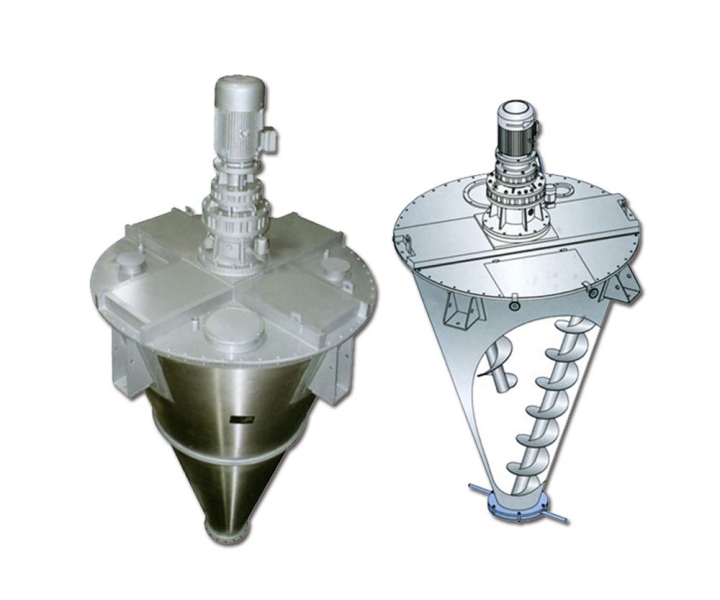

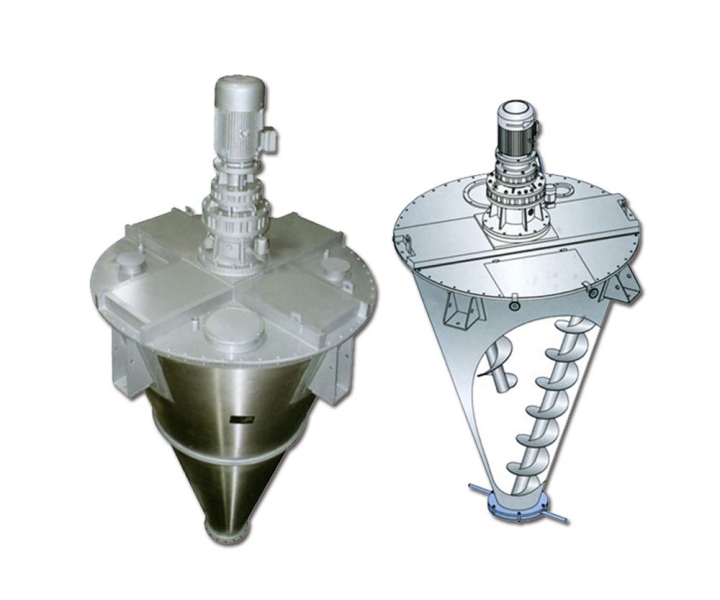

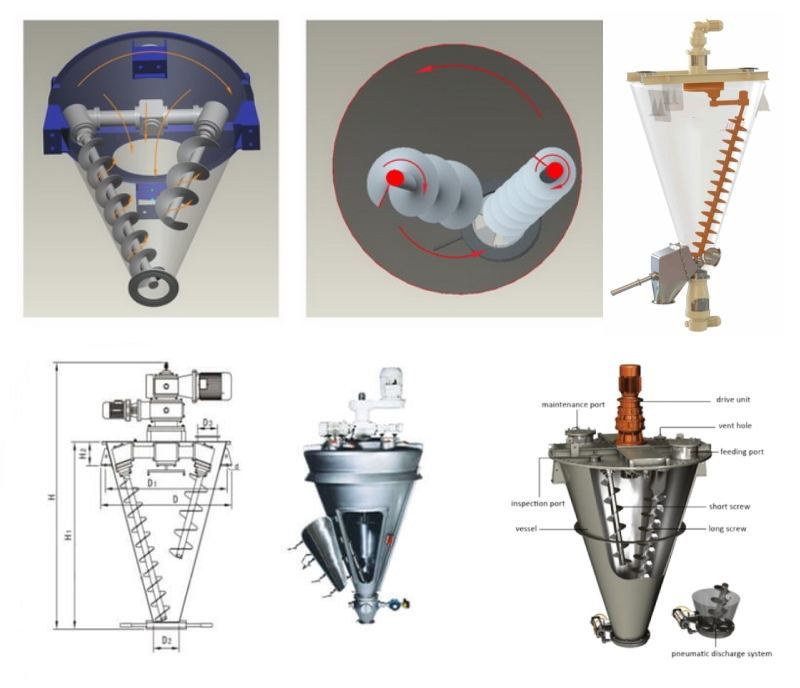

Vertical Screw Mixer is a common mixing equipment, mainly used to uniformly mix different types of materials. It adopts a vertical structure and consists of a main machine, a motor, a transmission device and a mixing screw. Through the rotation of the screw, the materials are pushed and rolled along the axial and radial directions of the screw in the mixer, thereby achieving uniform mixing of the materials. The vertical screw mixer has the characteristics of compact structure, easy operation and convenient maintenance, and is suitable for the mixing needs of chemical, pharmaceutical, food and other industries. It can improve mixing efficiency, ensure the uniformity of mixed materials, and meet different process and production requirements.

The working principle of the vertical screw mixer is to push and tumble the materials along the axial and radial directions of the screw through the rotation of the screw to achieve uniform mixing of the materials. The mixer has a compact structure and a small footprint, making it suitable for installation in workplaces with limited space. It can be used for mixing powdery, granular and viscous materials, and has the ability to mix efficiently and uniformly. The vertical screw mixer is easy to operate, and the mixing time and speed are adjustable to adapt to the mixing requirements of different materials. In addition, cleaning and maintenance are relatively easy, making it an important mixing equipment widely used in industrial production.

Vertical screw mixers have a wide range of applications. Common uses include but are not limited to the following aspects:

Food industry: Vertical screw mixers can be used to mix raw materials during food processing, such as mixing flour, seasonings, additives, etc., to ensure the uniformity and quality stability of food products.

Chemical industry: In chemical processes, vertical screw mixers can be used to mix different powder or granular chemical substances, such as pigments, dyes, plastic powders, etc., to achieve uniform mixing and reaction.

Pharmaceutical industry: In the pharmaceutical process, vertical screw mixers can be used to mix pharmaceutical raw materials, excipients and additives to ensure the uniformity and quality stability of the medicine and meet the requirements of pharmaceutical production.

Agricultural field: Vertical screw mixers play an important role in feed processing and can evenly mix different types of feed raw materials to improve the nutritional balance and feeding effect of the feed.

Environmental engineering:In the field of environmental protection, vertical screw mixers can be used to treat waste and sludge, mixing waste with different components to facilitate subsequent processing and disposal.

The working principle of vertical screw mixer is as follows:

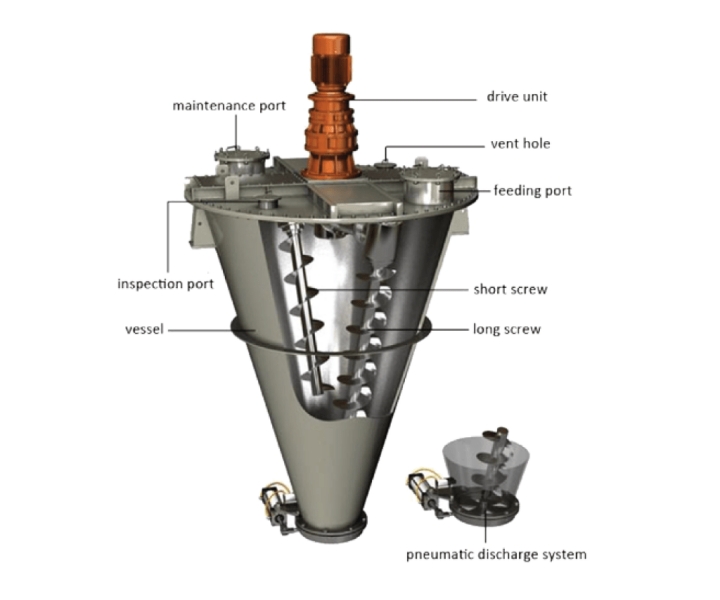

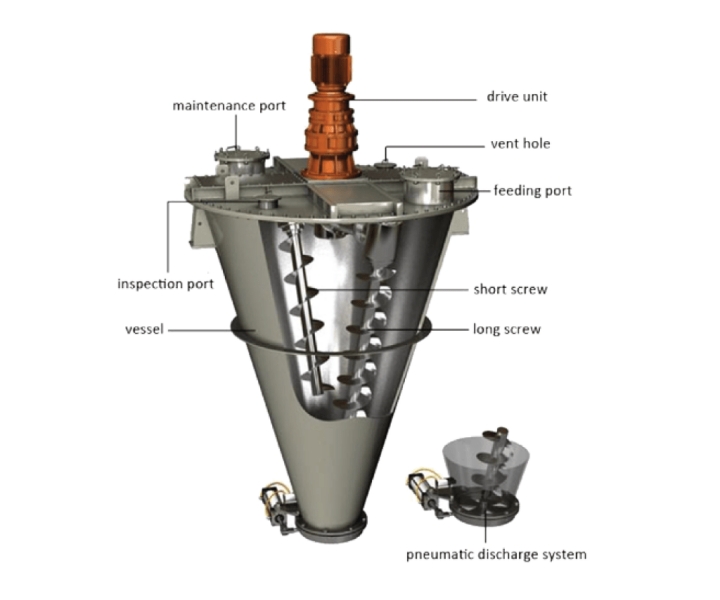

Mixing screw: There is a screw inside the vertical screw mixer, usually a spiral-shaped metal rod. The screw usually consists of a main shaft and a spiral blade, which can be fixed on the central axis of the main machine.

Material feeding: Add the materials to be mixed into the vertical screw mixer through the feeding port. Materials can be powders, granules or viscous materials.

Rotary motion: Start the motor to cause the spindle to start rotating, and the screw will rotate accordingly. The rotating motion of the screw pushes and tumbles the material along the axial and radial directions of the screw.

Mixing process: The material is continuously pushed upward and rolled downward under the action of the screw, and also diffuses radially around the screw. This pushing and rolling motion allows the materials to be fully mixed, thereby achieving a uniform mixing effect.

Mixing time and speed adjustment: The degree and time of mixing can be controlled by adjusting the motor speed and mixing time.

Mixing completion and unloading: When the mixing reaches the predetermined time or reaches the required uniformity, stop the motor. Then take out the mixed materials from the vertical screw mixer through the discharge port.

Efficient mixing

The vertical screw mixer uses the rotating motion of the screw to fully advance and tumble the materials to achieve efficient mixing effects. Materials can be evenly dispersed during the mixing process, improving mixing efficiency and quality.

Good uniformity

The rotating movement of the screw causes the materials to advance and roll radially and axially inside the vertical screw mixer, thereby achieving uniform mixing of the materials. The mixed materials have high uniformity, ensuring the quality stability of the product.

Compact structure

The vertical screw mixer has a compact structure design and a small footprint, making it suitable for use in limited work spaces. It usually has a simple operating interface and an easy-to-maintain structure for easy operation and maintenance.

Easy operation

The operation of the vertical screw mixer is relatively simple. You only need to start the motor through the control switch and adjust the speed and mixing time. Operators can easily master operating skills and improve production efficiency.

Strong adaptability

The vertical screw mixer is suitable for the mixing needs of a variety of materials, including powders, granules and viscous materials. It can meet the mixing requirements of different industries, such as food, chemical, pharmaceutical and agricultural fields.

Easy maintenance

The vertical screw mixer has a relatively simple structure and is easy to clean and maintain. The screw can usually be disassembled and the mixing chamber cleaned to facilitate material replacement or routine maintenance, improving the reliability and service life of the equipment.

| Model | Total volume(L) | Capacity(kg) | Mixing time(Minutes) | Power(kw) | Total height(m) | Weight(kg) | |

| CF-DSH-1 | 1000 | 400-600 | 5-10 | 4 | 2775 | 1200 | |

| CF-DSH-2 | 2000 | 800-1200 | 5-10 | 5.5 | 3424 | 1500 | |

| CF-DSH-6 | 6000 | 2400-3600 | 5-10 | 15 | 4960 | 3500 | |

| CF-DSH-8 | 8000 | 3200-4800 | 5-10 | 18.5 | 5378 | 4000 | |

| CF-DSH-10 | 10000 | 4000-6000 | 5-10 | 18.5 | 5678 | 4300 | |

| CF-DSH-12 | 12000 | 4800-7200 | 5-10 | 22 | 6015 | 4500 | |

| CF-DSH-15 | 15000 | 6000-9000 | 5-10 | 30 | 6650 | 5000 | |

| CF-DSH-20 | 20000 | 8000-12000 | 5-10 | 37 | 7176 | 6000 |

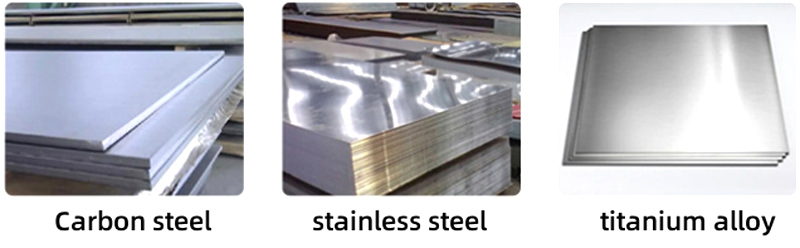

Various materials available

Carbon steel materials, various stainless steel materials, titanium alloys, high manganese steel and other materials can be selected.

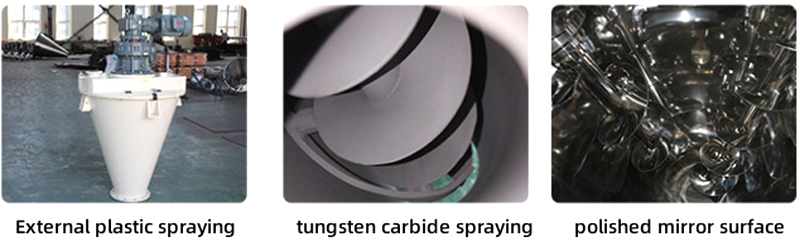

Surface treatment process

Spray painting, plastic spraying, special coating on the inner surface, brushed stainless steel surface polishing, mirror polishing, etc.

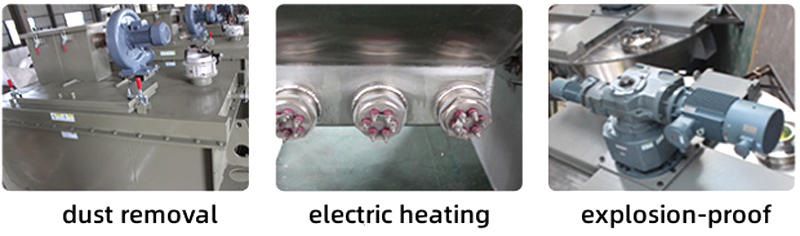

Functional choices

Dust removal, ventilation and drying, explosion-proof, material level sensing, lid opening sensor, etc.

Material input and export customization

Support customization of non-standard inlet and outlet.

Drive form: manual, electric, pneumatic.

A food processing plant uses a vertical screw mixer to mix a variety of food ingredients to improve product quality and taste. Their products include a variety of seasonings and powdered food ingredients such as flour, powdered sugar, salt and spices. The vertical screw mixer's high-efficiency mixing and good uniformity ensure that the raw materials are fully mixed, making the final product more balanced and consistent in texture and taste. The mixer has a compact structure and small footprint, adapting to the limited space of the factory. The easy-to-operate design allows operators to get started quickly and improves production efficiency. In addition, the maintenance of the mixer is also very convenient. Regular cleaning and maintenance can ensure the normal operation of the equipment.

Xinxiang Dahan vertical screw mixer manufacturer is a company specializing in manufacturing vibration equipment and one of the vertical screw mixer manufacturers. The company has many years of industry experience and advanced production technology, and is committed to providing high-quality, reliable and efficient products. The vertical screw mixer adopts high-quality materials and precision processing technology, with stable performance and long life. This product has reasonable design, easy operation and excellent mixing effect. Xinxiang Dahan vertical screw mixer has won wide recognition from customers for its excellent manufacturing capabilities and good after-sales service. Is one of the trustworthy vertical screw mixer manufacturers.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.