Double Shaft Paddle Mixers for powder mixing utilize a horizontal cylinder housing two parallel paddle-equipped mixing shafts. As the shafts rotate in opposite directions, the paddles, designed at a special angle, toss the powder upward, creating a weightless mixing state and significantly reducing powder stratification. The mixers typically have a single feed capacity of 25-100 kg. The material-contacting portion of the mixer can be constructed of carbon steel or 304 stainless steel to accommodate different powder characteristics. Some models can be equipped with explosion-proof and temperature-control components, offering convenient operation and low discharge residue. These mixers are a cost-effective option for mixing small to medium-sized batches of powders.

Twin Shaft Paddle Mixer are commonly used for powder mixing and have a wide range of applications. They offer uniform mixing, high efficiency, adaptability, and ease of operation. In industries such as pharmaceuticals, chemicals, food, and metallurgy, twin-shaft paddle mixers play an important role, improving production efficiency and ensuring product quality.

When choosing the best twin-shaft paddle mixer for powder mixing, you need to consider several factors, including the nature of the materials being mixed, the mixing effect required, and the scale of production.

V-Shaped Twin-Shaft Paddle Mixer: It has two shafts, each with paddles installed to form a V-shaped structure. This design helps to increase the mixing effect. It is suitable for mixing materials with smaller powder particles and different densities, and the mixing effect is relatively uniform.

Spiral Twin-Shaft Paddle Mixer: It has a spiral-shaped paddle that can achieve better mixing effect, especially for powder materials with higher viscosity. It is suitable for occasions where powders need to be evenly mixed and stirred, especially for materials with high viscosity.

High Shear Twin-Shaft Paddle Mixer: It has high-speed rotating paddles that can generate higher cutting and shear forces, and is suitable for powder materials that need to be mixed and dispersed quickly.

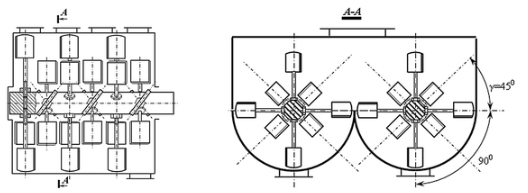

The twin-shaft paddle mixer, with its unique bidirectional rotating paddle design, achieves deep mixing of powder materials in 30-90 seconds through a three-way, compound, cyclic motion of radial, axial, and tangential directions, precisely addressing common powder mixing challenges.

High mixing efficiency: The dual-shaft counter-rotating paddles create a "gravity-free mixing state," breaking up powder agglomerates. Even powders with large differences in specific gravity and particle size achieve a mixing uniformity of over 98%, eliminating stratification.

Adaptability: The carbon steel or stainless steel body, with its wear-resistant coating, can handle everything from common chemical powders and food additive powders to high-abrasion mineral powders. It can also accommodate small amounts of liquids.

High efficiency and low residue: The twin-shaft mixing creates strong convection, reducing mixing time by 30% compared to single-shaft equipment. The bottom discharge design, equipped with a cleaning device, ensures a discharge residue rate of ≤0.3%, minimizing material waste. Customizable: The source manufacturer can customize production according to the customer's site and production needs, and complete the high-speed operation of the entire production line.

The working principle of the twin shaft paddle mixer is to use the rotation and interaction of the paddles to achieve mixing. It usually consists of two horizontally mounted shafts and multiple paddles. When the equipment is started, the two shafts rotate at high speed in opposite directions, and the paddles continuously shear, fold, and spread the powder during the rotation to fully mix it. The design and layout of the paddles can be adjusted according to different mixing requirements to ensure uniformity and efficiency of mixing.

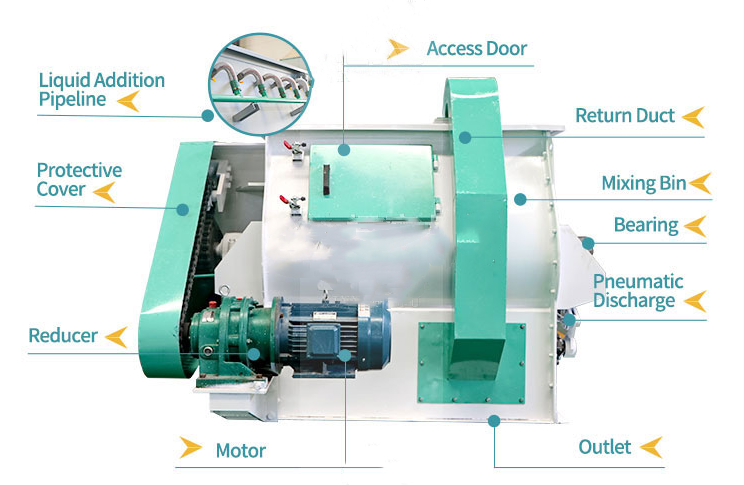

Double Shaft Paddle Mixers for powder mixing consist of five key components. Through dual counter-rotating shafts and a specialized paddle design, they achieve axial and radial tumbling of the material, resulting in rapid and uniform mixing.

Horizontal Mixing Cylinder: Mostly U-shaped or trough-shaped, the powder-contacting areas are constructed of carbon steel or 304/316L stainless steel. The smooth interior reduces powder residue, and some models can be equipped with heating/cooling jackets to meet temperature control requirements.

Double Shaft Paddles: Staggered blades are arranged on two parallel horizontal shafts. These blades are spiral or plow-shaped and feature a wear-resistant finish. The counter-rotating shafts create convection and are the core of weightless mixing.

Power Drive System: Composed of dual motors, a hardened gear reducer, and a coupling, these shafts ensure synchronized speeds and provide stable torque for powder mixing.

Inlet and Outlet System: A top loading port and a pneumatic/electric discharge valve at the bottom ensure rapid discharge with minimal residue. PLC control system: can set mixing time and speed, some models have fault alarm function, easy to operate, suitable for different powder mixing processes.

| model | SJ-30 | SJ-32 | SJ-35 | SJ-40 | SJ-42 | SJ-46 | SJ-50 | SJ-60 |

| Center distance between two axes/mm | 300 | 320 | 350 | 400 | 420 | 460 | 500 | 600 |

| Spindle speed/(r/min) | 53 | 53 | 53 | 53 | 53 | 53 | 45 | 45 |

| Tank length/mm | 2000-4000 | 2000-4000 | 2000-4000 | 2000-4000 | 2000-4000 | 2000-4000 | 2000-4000 | 2000-4000 |

| Equipment capacity/m³ | >6-8 | >8-10 | >10-13 | >13-24 | >24-28 | >28-35 | >35-38 | >38-80 |

| Motor power/kW | 22 | 30 | 37 | 45 | 55 | 75 | 75 | 110 |

Double Shaft Paddle Mixers for powder mixing utilize dual-shaft reverse-direction paddles to create zero-gravity mixing, quickly breaking up powder agglomerates and eliminating specific gravity differences, making them suitable for powders from a variety of industries.

Efficient mixing: The double-shaft design of the double-shaft paddle mixer greatly improves its mixing efficiency. The two mixing shafts rotate in opposite directions, and the paddles are staggered, which can quickly flip and push the powder materials, allowing different powders to fully contact and fuse in a short time.

High mixing uniformity: The unique shape and arrangement of the paddles can produce complex material flow patterns during the mixing process, causing the powders to intersperse and convect in all directions and at multiple angles.

Wide range of applications: It can handle powders with good fluidity, and can also effectively mix powders with certain viscosity and agglomeration.

Low residue: The internal structure of the mixer is reasonably designed, the gap between the paddles and the barrel wall is small, and the material is not easy to accumulate and remain during the mixing process.

Strong equipment durability: It is usually made of high-quality steel, and the mixing shaft and paddles are specially treated with high strength and wear resistance. In the process of long-term and frequent mixing of powder materials, it can withstand large torque and impact.

Double Shaft Paddle Mixers for powder mixing can be used to mix flour, seasoning powder, food additive powder, pigment powder, plastic masterbatch, cement powder, etc., and can easily handle powders that are prone to agglomeration and have large specific gravity differences.

Chemical raw material powder: Like calcium carbonate powder, it is often used as a filler in the plastic, rubber and other industries. It can be evenly mixed with other additives in a double-shaft paddle mixer.

Food raw material powder: For example, milk powder needs to be mixed with other powders such as nutritional enhancers and flavorings during the production process. The double-shaft paddle mixer can gently and evenly complete this mixing operation.

Medical raw material powder: In the production of medicines, the powder of active ingredients of medicines needs to be accurately mixed with the powder of auxiliary materials. The double-shaft paddle mixer can mix them evenly to ensure the accuracy of the dosage of the medicine and the stability of the efficacy.

Metal powder: In the fields of metal processing, 3D printing, etc., metal powders such as iron powder and aluminum powder often need to be mixed with additives to improve performance. The double-shaft paddle mixer can promote the uniform dispersion of metal powders to meet the requirements of subsequent processing.

Ceramic powder: In ceramic production, when ceramic powders such as kaolin are mixed with other additives, the double-shaft paddle mixer can make them fully blended.

Double Shaft Paddle Mixers for powder mixing offer a wide range of optional components, including explosion-proof motors for flammable and explosive powders, 304/316L stainless steel components for corrosion resistance, and heating/cooling jackets for temperature control.

Surface treatment options: internal high-precision mirror polishing, external polishing options, matte or mirror external polishing are available. Matte polishing makes the appearance of the equipment more low-key and wear-resistant, which is suitable for scenes with certain requirements for appearance texture and complex use environment; mirror external polishing can make the equipment more shiny, which is more suitable for some enterprises that have requirements for the appearance display of the equipment.

Chopper configuration: equipped with a chopper, it can enhance the stirring effect during the mixing process, and effectively break up the block materials to ensure uniform mixing of the materials.

CIP system installed on demand: The CIP (cleaning in place) system can be installed according to user needs. It can automatically clean the inside of the mixing chamber without disassembling the equipment.

Heating/cooling jacket: Setting a heating or cooling jacket can accurately adjust the temperature of the material during mixing according to the requirements of the powder mixing process.

Cryogenic treatment (Cryogenic execution): Using cryogenic technology, the physical properties of the material can be changed, making some difficult-to-mix powders easier to mix evenly at low temperatures, while also improving the stability and performance of the product.

Packaging system for mixed products: The packaging system for matching mixed products can package the product immediately after mixing is completed, realizing integrated production and packaging operations.

Selecting the right double-shaft paddle mixer for powder mixing requires considering production requirements and material properties. Four key considerations can be taken into account to ensure precise matching of the equipment's core structure.

Select specifications based on production capacity and feed volume: Determine the cylinder capacity based on the single-time powder processing volume (e.g., a small machine for 25-50kg, a medium machine for 50-100kg). Also, consider the average daily production capacity to match the equipment speed to avoid over-proportioning or wasting production capacity.

Select the material and structure based on powder characteristics: For corrosive powders, choose a 316L stainless steel cylinder; for food/pharmaceutical-grade powders, choose 304 stainless steel. Highly abrasive powders require a wear-resistant coating on the paddles.

Select functional configurations based on process requirements: For powders requiring temperature control, choose a model with a heating/cooling jacket. For flammable and explosive powders, an explosion-proof motor and control system are essential. For precise batching, an automatic weighing and feeding device can be added.

Consider ease of operation and maintenance: A PLC and touchscreen control system is preferred for easy setting of mixing parameters and troubleshooting. Pay attention to the discharge design; a bottom pneumatic or electric discharge valve can reduce residual material.

Over the years, Dahan Machinery has focused on the research and development and manufacturing of powder mixing twin-shaft paddle mixers, creating products with mature technology and excellent performance. They are widely used in many industries such as chemical, food, medicine, mining, and building materials. The equipment is durable and the mixing effect is highly praised by customers. In terms of model diversity, there are large-scale equipment such as 2000L suitable for large-scale production enterprises, equipped with high-power motors, which can handle a large amount of powder materials at a time to meet the efficient mixing needs of continuous production, and small models such as 50L suitable for small processing plants or laboratories. It occupies a small area, is easy to operate and has low energy consumption, and can accurately complete small batch powder mixing tasks. If you also have mixing needs, please contact us for detailed information!

Address:China,Yanjin county forest park gate to the west 1000 meters north road.