A device that uses a gravity-free environment for mixing to achieve uniform mixing of materials by simulating the space environment

![]()

![]()

Price:$2,000.00-$10,000.00/Set

Consult now and enjoy a 10% discount

Mixing time: 8-20min

Voltage: 380V/220V/450V

One-time mixing: 100-6000kg

Mixing speed: 15-60r/min

Power: 3-75kw

Weight: 500-7500kg

Feeding method: manual feeding, automatic feeding or other methods

Discharging method: manual unloading, automatic unloading or other methods

Application: Food industry, pharmaceutical industry, chemical industry, building materials industry, metallurgical industry.

Commitment: Free Shipping/5 Days Delivery/30-Day Returns/Support Customization

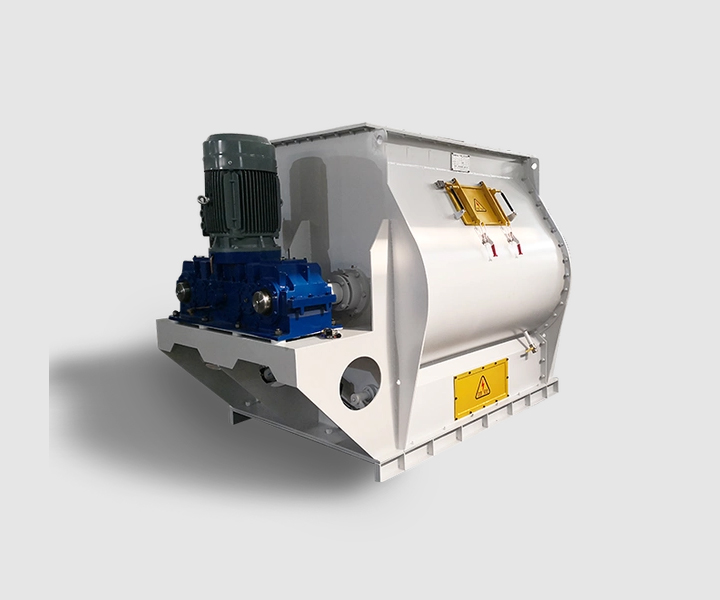

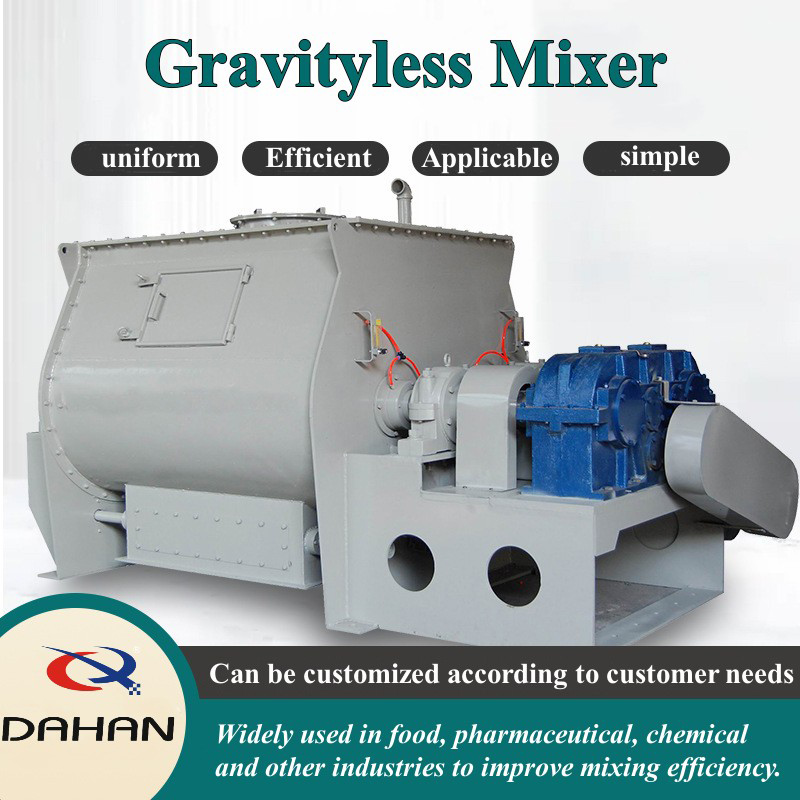

Gravityless Mixer is a special device that uses the gravity-free state in a vacuum environment to perform the mixing process. It creates a vacuum environment in a closed container so that materials can be freely suspended and mixed under gravity-free conditions, thereby achieving efficient and uniform mixing effects. Gravityless mixers are widely used in food, pharmaceutical, chemical and other industries to improve mixing efficiency and product quality while improving production efficiency.

The working principle of the gravityless mixer is to use the gravity-free state in the vacuum environment to make the materials freely suspended and mixed in the container. In the gravity-free state, the density and viscosity of the material have less impact on the mixing process, and faster and more uniform mixing can be achieved. This equipment has the characteristics of high efficiency, uniformity and applicability, and can meet the mixing needs of different industries. Through gravityless mixer, companies can achieve better product quality control and production efficiency improvements, bringing greater convenience and advantages to the production process.

Gravityless mixers have a wide range of uses and are suitable for multiple industries and fields. Here are some common uses for gravity-free mixers:

Food industry: Gravityless mixer can be used for mixing and uniform dispersion of food additives. It can mix different types of food additives together to ensure the quality and stability of food. For example, in the production of pastries, biscuits, condiments and other foods, gravityless mixers can mix various additives, spices and powder materials evenly to provide consistent taste and quality.

Pharmaceutical industry: Gravityless mixers also have important applications in the pharmaceutical industry. It can be used for mixing and even dispersion of drug formulations to ensure the uniformity and stability of the drug. Gravityless mixers can mix different pharmaceutical ingredients together to prepare solid dosage forms, capsules or granular drugs, etc. It provides an efficient and precise mixing process, ensuring drug quality and consistency.

Chemical industry: gravityless mixers are widely used in the chemical industry. It can be used to mix different kinds of chemicals, powders, granules, etc. to achieve uniform mixing and reaction. Gravityless mixers play an important role in the production of chemical products such as polymers, dyes, pigments, and plastics, ensuring the stability of product quality and performance.

Building materials industry:In the building materials production process, gravityless mixer can be used to mix cement, gypsum, pigments and other materials to prepare uniform concrete, mortar, paint and other products. It blends different ingredients together quickly and efficiently, delivering consistent product quality and performance.

The working principle of gravityless mixer is to use the gravity-free state in a vacuum environment to achieve the mixing process. Here is the basic working principle of gravityless mixer:

Create a vacuum environment: First, the gravityless mixer creates a vacuum environment through airtight containers and vacuum pumps and other equipment. The air pressure in a vacuum environment is low, which can eliminate air and oxygen, thereby achieving a gravity-free state.

Material Suspension: Once the vacuum environment is established, the material is placed into the mixer container. In the gravity-free state, the density and viscosity of the material have less impact on the mixing process, allowing the material to be freely suspended in the container.

Mixing process: Once the material is suspended in the container, the gravityless mixer begins the mixing process. Usually, the mixer is equipped with a stirrer or other mixing device, which can stir, turn and rotate the materials in a gravity-free state to achieve the purpose of mixing.

Mixing effect:In the gravity-free state, the materials are suspended and mixed quickly, and the mixing effect is good. Due to the free movement of materials in a gravity-free state, they will not be affected by gravity, making the mixing more uniform and thorough.

End mixing:After the mixing process is completed, you can stop the gravityless mixer operation. The materials in the container can be restored to normal atmospheric pressure by opening the airlock or other means, and then the mixed materials can be taken out.

Efficiency

The gravityless mixer can achieve a fast and efficient mixing process in a gravity-free environment. Since the materials are freely suspended and moving in a gravity-free state, the mixing speed is faster, the mixing effect is more uniform and thorough, and the mixing time and energy consumption are saved.

Uniformity

gravityless mixer can achieve uniform mixing of materials. In the gravity-free state, the density and viscosity of the material have less impact on the mixing process, allowing materials with different components to be fully mixed to ensure product consistency and quality.

Applicability

gravityless mixer is suitable for mixing a variety of materials and particles. Whether powders, granules, solids or liquids, different types of materials can be mixed in a gravity-free environment. This makes gravity-free mixers widely used in many industries such as food, pharmaceuticals, chemicals, and building materials.

Avoid contamination

Since the gravityless mixer operates in a vacuum environment, it can avoid the entry of outside air and oxygen, reducing oxidation, pollution and the growth of microorganisms. This helps maintain the purity and stability of materials and improves product quality and shelf life.

Flexibility

gravityless mixers can be adjusted and customized for different mixing needs. The size, shape and design of the mixing device can be adjusted to accommodate different sizes and types of production. This makes the gravity-free mixer highly flexible and adaptable.

Cost savings

With gravityless mixers, companies can achieve higher mixing efficiency and production efficiency, reducing mixing time and energy consumption. In addition, due to more uniform and thorough mixing, the generation of waste materials and defective products is reduced, and production costs and losses are reduced.

| Model | LHY-0.25 | LHY-0.5 | LHY-1 | LHY-1.5 | LHY-2 | LHY-3 | LHY-4 | LHY-6 | LHY-8 | LHY-10 |

| One-time mixing (kg) | 100-150 | 200-300 | 400-600 | 600-900 | 800-1000 | 1200-1800 | 1600-2400 | 2400-3600 | 3200-4800 | 4000-6000 |

| Mixing time (min) | 8-20 | 8-20 | 8-20 | 8-20 | 8-20 | 8-20 | 8-20 | 8-20 | 8-20 | 8-20 |

| Mixing speed (r/min) | 60 | 55 | 45 | 40 | 35 | 25 | 25 | 20 | 15 | 15 |

| Motor power (kw) | 3-5.5 | 4-11 | 7.5-15 | 11-18.5 | 15-22 | 18.5-30 | 22-37 | 37-55 | 37-55 | 45-75 |

| Weight (kg) | 500 | 900 | 1800 | 2500 | 3200 | 4100 | 5100 | 6300 | 7500 |

A food manufacturing company needs to mix a variety of food additives during the production process to improve product quality and stability. They decided to introduce gravityless mixer to meet their mixing needs. This gravity-free mixer has the characteristics of high efficiency, uniformity and applicability, and can quickly and thoroughly mix different types of food additives in a vacuum environment. By using the gravityless mixer, the food manufacturing company successfully achieved uniform mixing of food additives, improved product quality and stability, and reduced the generation of waste and defective products. At the same time, the company also saves production costs because the mixing process is more efficient and energy-saving. This case demonstrates the application advantages of gravityless mixer in the food manufacturing industry, providing customers with an efficient and reliable solution to their mixing needs.

Xinxiang Dahan gravityless mixer manufacturer is a company specializing in manufacturing vibration equipment and one of the gravityless mixer manufacturers. The company has many years of industry experience and advanced production technology, and is committed to providing high-quality, reliable and efficient products. The gravityless mixer adopts high-quality materials and precision processing technology, with stable performance and long life. This product has reasonable design, easy operation and excellent mixing effect. Xinxiang Dahan gravityless mixer has won wide recognition from customers for its excellent manufacturing capabilities and good after-sales service. Is one of the trust worthy gravityless mixer manufacturers

Address:China,Yanjin county forest park gate to the west 1000 meters north road.