Used for mixing granular powder materials in feed production lines, mixing time is 3-5 minutes, the material is discharged quickly and there is less residual material

![]()

![]()

Price:$500.00-$4,500.00/Set

Consult now and enjoy a 10% discount

One-time mixing: 300-3000 (kg) (If it exceeds 6000kg, it can be customized according to needs)

Voltage: 380 Volt、Special customized 400v、 480v (Can be specially customized according to customer requirements)

Mixing time: 8-20min

Frequency: 50HZ、60HZ

Mixing speed: 15-60r/min

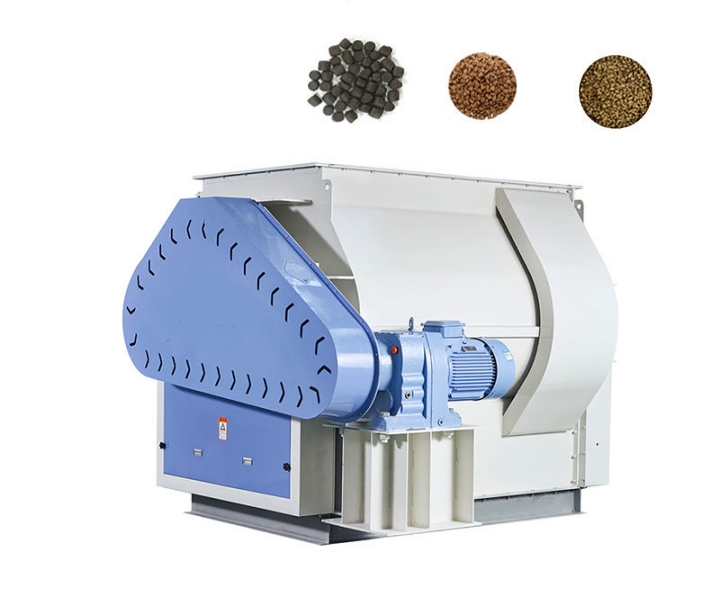

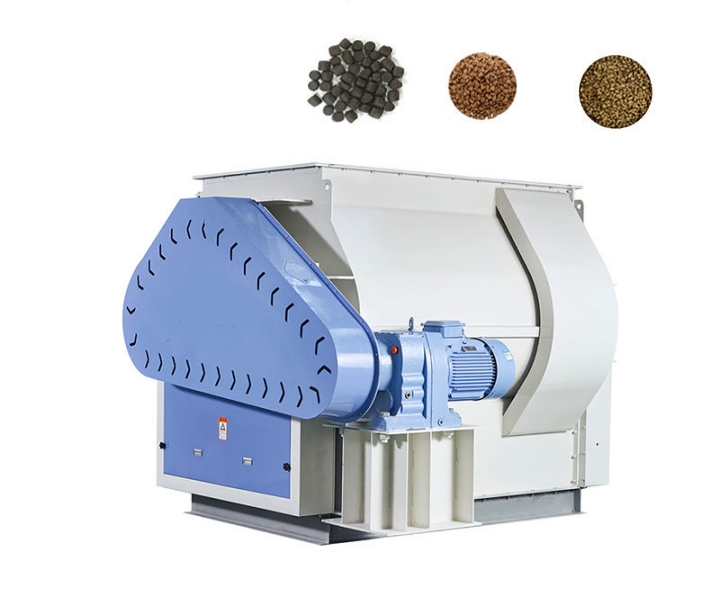

Application: Animal feed paddle mixer can be used to mix various animal feed raw materials, including grains (such as corn, wheat), soybean meal, fish meal, oil, forage, mineral additives, etc.

Commitment: Free Shipping/5 Days Delivery/30-Day Returns/Support Customization

Animal feed paddle mixer is mainly used in some large feed mills for mixing and mixing of feed. After the feed material enters the mixer, the leaves will drive the material to rotate counterclockwise along the inner wall of the machine groove on the one hand, and on the other hand, it will drive the material to turn left and right. , so that the material can be fully mixed.

The Animal feed paddle mixer has a special channel for adding liquid. The liquid can enter the feed mixer through this channel for stirring. This type of feed mixer generally belongs to the wet and dry type. The mixing uniformity and time are ideal, and the mixing time of a batch of materials is only about 0.5-2 minutes.

Animal feed paddle mixers are widely used in poultry farms, farmers' home breeding, feed processing plants and other places. The following are its main application scenarios:

Poultry farms: During the poultry breeding process, different types of feed ingredients need to be mixed to meet the poultry's needs for various nutrients. The paddle mixer can fully mix grains, soybean meal, fish meal and other raw materials to improve the uniformity and nutritional value of feed and ensure a balanced feed supply for poultry.

Farmers' family breeding: Many farmers need to prepare their own feed in family breeding to reduce costs and improve breeding efficiency. The paddle mixer can help farmers mix various feed ingredients to ensure the uniformity and nutritional balance of the feed, and improve the growth and egg production capabilities of poultry or livestock animals.

Feed processing plants: Large-scale feed processing plants usually need to mix large amounts of feed ingredients to produce feed products that meet standards. Paddle mixers play a key role in the feed processing process and can efficiently mix different types and proportions of raw materials to ensure the uniformity and quality stability of feed products.

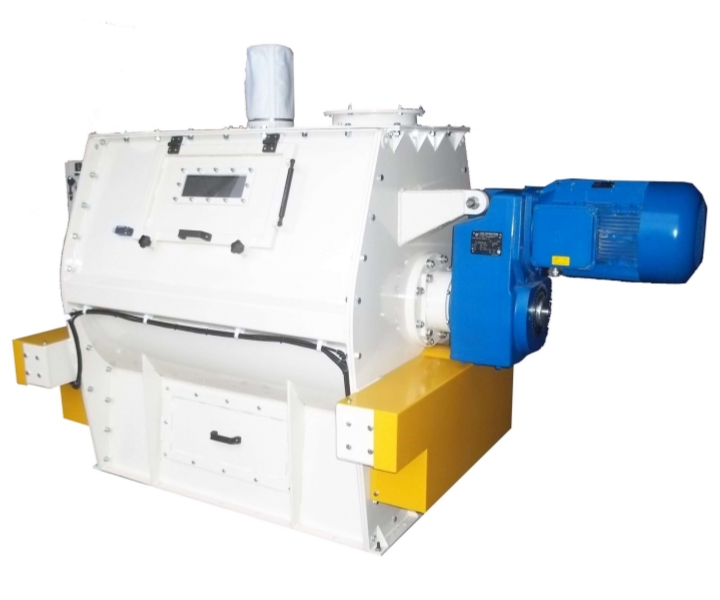

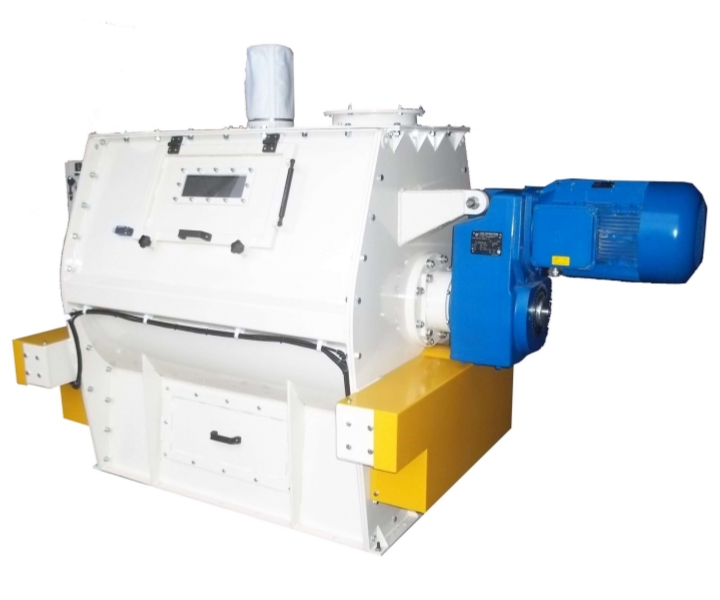

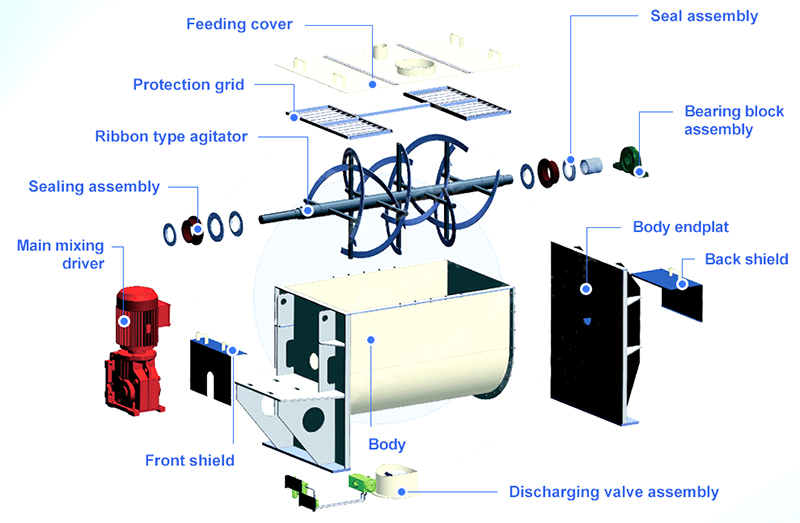

Animal Feed Paddle Mixer is a high-efficiency mixing equipment designed for animal feed production. Its main components include the following parts:

Mixing bin: It is the main component that bears the material. It is usually made of stainless steel or carbon steel. The bin body is designed to be cylindrical or U-shaped.

Agitator: The agitator is used to rotate and stir the material. It is usually made of high-strength steel. The paddle is installed at a certain angle to ensure that the material is evenly mixed during the mixing process.

Feed port and discharge port: The feed port is located at the top of the mixing bin to facilitate the rapid entry of materials. The discharge port is located at the bottom and is designed as a pneumatic or manual valve to facilitate rapid unloading.

PLC control system: It includes an electrical control cabinet and an operation panel, and supports manual or automatic operation modes.

Support frame: The support frame supports the stable operation of the equipment at the bottom of the whole machine. It can be adjusted according to user needs and is convenient for use with other equipment.

The mixing of feed ingredients is achieved through the rotation and pushing of the paddles. The machine usually consists of a mixing barrel and a motor drive system. When working, the motor transmits power to the paddle through the transmission device, causing it to start rotating. The paddle is located inside the mixing barrel and can rotate along the axis or push on the horizontal plane. When the paddle rotates, the feed ingredients are pushed to one side of the mixing barrel, then rise along the inner wall of the mixing barrel, and finally fall evenly from the top. During this process, the feed ingredients are continuously thrown and mixed by the push and rotation of the paddles.

It has high mixing uniformity, no dead angle in mixing, and mixing time is 3-5 minutes.

The bottom full-length door opening structure is adopted for discharging, and the discharging is fast and the residual amount is low.

The loading capacity has a large variable range. The machine can be equipped with a grease adding pipeline, and various liquids can be added in an appropriate amount.

Closed operation, stable operation, low noise, low dust concentration, no pollution to the environment.

Animal feed paddle mixers can be divided into the following three types:

Vertical animal feed paddle mixer: The paddle design of this mixer allows the mixed materials to be mixed in the vertical direction. It is suitable for small-scale production, simple operation, good mixing effect, and is suitable for mixing raw materials of different particle sizes and densities.

Horizontal animal feed paddle mixer: The paddle design allows the mixed materials to be mixed in the horizontal direction. This mixer is suitable for large-scale production, has a uniform mixing effect, and is suitable for mixing a variety of raw materials.

Double shaft animal feed paddle mixer: It has two shafts, each with paddles, making the mixing more thorough and uniform. This mixer has a more complex structure and is suitable for occasions that require more detailed mixing.

Paddle mixers and ribbon mixers are common feed mixing equipment. They have some differences in the way they mix raw materials and their working principles.

| Comparative Item | Paddle mixer | Ribbon mixer |

|

|

|

| Mixing principle | Mixes the feed ingredients through the rotation and push of the paddles | Uses spiral stirring blades to push the raw materials forward to achieve mixing |

| Structural design | Paddle mixers usually have a mixing barrel and a motor drive system, with the paddles located inside the mixing barrel. | The ribbon mixer consists of a spiral mixing blade, usually located in a rectangular or cylindrical mixing chamber. |

| Mixing effects | Because the mixing method of the paddle mixer is more vigorous, it can better achieve uniform mixing of feed ingredients and ensure better mixing effects. | During the mixing process of the ribbon mixer, the raw materials turn and move relatively little, and the mixing effect may be slightly inferior to that of the paddle mixer. |

| Scope of application | Commonly used in poultry breeding, household breeding, and large-scale feed processing plants. They are suitable for mixing various feed ingredients. | Suitable for feed processing, pellet processing, chemical industry and other industries, and is suitable for mixing powdery or granular materials. |

| Model | Volume(m³) | One-time mixing(kg) | Motor power(kw) | Weight(kg) |

| WZL-1 | 1 | 300-500 | 7.5-11 | 1600 |

| WZL-2 | 2 | 600-1000 | 11-15 | 2300 |

| WZL-3 | 3 | 1000-1500 | 18.5-22 | 2900 |

| WZL-4 | 4 | 1200-2000 | 22-30 | 4800 |

| WZL-5 | 5 | 1800-3000 | 30-37 | 6000 |

Xinxiang Dahan animal feed paddle mixer manufacturer is a professional manufacturer of animal feed paddle mixers. The company has many years of experience and expertise in developing and producing high-quality feed mixer equipment.

Xinxiang Dahan's paddle mixer adopts advanced design and manufacturing technology and is characterized by high efficiency, durability and stability. The machine is made of high-quality materials, has a compact structure and is easy to operate. It can achieve uniform mixing of different feed ingredients to ensure the quality and nutritional balance of the feed. Xinxiang Dahan animal feed paddle mixer manufacturer focuses on product quality and customer satisfaction. Its products undergo strict quality control and testing, and it provides comprehensive pre-sales consultation and after-sales services to meet customer needs.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.