Suitable for mixing various feed raw materials, including powders, granules, additives, etc.

![]()

![]()

Price:$300.00-$2,000.00/Set

Consult now and enjoy a 10% discount

Mixing time: 6-15min

Capacity: 50-5000L

Mixing speed: 0-15r/min

Swing height: 2850mm

Material: stainless steel

Application: corn meal, soybean meal, fish meal, bone meal, vitamins, amino acids, minerals, distillers grains, and brewer grains.

Commitment: Free Shipping/5 Days Delivery/30-Day Returns/Support Customization

Rotary drum feed mixer is a piece of equipment commonly used in the livestock and poultry breeding industry to evenly mix different types of feed ingredients. It mainly consists of a rotating drum, mixing device and transmission system. This mixing method effectively improves the uniformity and solubility of the feed, ensuring that animals receive a balanced supply of nutrients.

Rotary drum feed mixer is suitable for mixing various types of feed ingredients, including powders, granules, additives, etc. It has the advantages of good mixing effect, easy operation and convenient maintenance, and is widely used in farms and feed processing plants. By using a drum feed mixer, the quality of feed can be improved, feed waste reduced, and breeding efficiency improved.

The rotary drum feed mixer has a wide range of application scenarios in many industries. The following is a detailed description:

Livestock and poultry breeding industry: used to mix different types of feed raw materials and additives to prepare balanced and nutritious feed to promote the growth and health of livestock and poultry.

Aquaculture industry:used to mix aquatic feed and additives to ensure the uniformity and nutritional balance of the feed, and improve the output and quality of aquaculture.

Pet food industry: used to mix pet food raw materials to prepare balanced and nutritious pet food to meet the nutritional needs of pets.

Feed processing industry: used to uniformly mix feed raw materials of different ingredients to prepare high-quality feed products to meet the needs of different breeding industries.

Farms and farmers: used in small-scale farms and family farms to mix feed ingredients to provide balanced and nutritious feed for farm livestock and poultry.

Feed seller: Used by feed dealers and wholesalers to mix different types of feed raw materials and provide high-quality feed products to farmers and farmers.

Rotary drum feed mixer can be used to mix various types of feed ingredients:

Feed pellets: including feed pellets, granular additives, etc.

Feed powder: including feed powder, powdery additives, etc.

Feed raw materials:including grains, beans, fish meal and other feed raw materials.

Additives: ncluding vitamins, minerals, enzymes and other additives.

Feed formulation: Feed formulation including different ingredients.

Pet food:including dog food, cat food and other pet food.

The working principle of the rotary drum feed mixer is to uniformly mix the feed through the rotation of the drum and the action of the internal stirring device. Here's a brief description of how it basically works:

Drum rotation:Rotary drum feed mixer usually consists of a large cylindrical drum. The drum is driven by a motor, gear transmission or hydraulic system to rotate at a certain speed.

Feed input: Put the feed ingredients and additives to be mixed into the drum. These raw materials can be granular feed, powdered feed or other forms of feed ingredients.

Internal stirring device:Inside the drum, there are usually one or more stirring devices, such as stirring blades, stirring arms, etc. These devices move as the drum rotates, stirring the feed ingredients from one end of the drum to the other to achieve mixing.

Mixing process: hen the drum rotates, the internal stirring device will continuously throw the feed ingredients from the top to the bottom, or push them from one side to the other. In this way, the feed ingredients will be continuously turned, collided and mixed inside the drum to achieve a uniform mixing effect.

Mixing completion and discharge:After a period of mixing, after the feed raw materials meet the requirements of uniform mixing, the discharge port of the drum can be opened to discharge the mixed feed.

High mixing uniformity

Use a rotating drum and internal mixing device,so it has extremely high mixing efficiency and excellent mixing uniformity.

No residue

No cross contamination, no dead angle between the inside of the cylinder and the contact part of the material, the mixing process is mild, no segregation occurs, the material is discharged completely.

Stable and durable

There is no mechanical extrusion and strong wear, and the material particles can be kept intact. The inside and outside of the barrel are polished, and both are designed to have a smooth transition.

Long lasting

The whole machine is made of 304 stainless steel, corrosion resistance, long life, simple operation and convenient maintenance.

Convenient to add ingredients

The discharge port is equipped with a butterfly valve, which is convenient for feeding.

Low energy consumption

It adopts advanced transmission system and energy -saving design to reduce energy consumption and reduce production costs.

| Comparative Item | Rotary drum feed mixer | Spiral feed mixer | Paddle type feed mixer | Horizontal twin-shaft feed mixer |

| Photo |  |

|

|

|

| Features | Uniform mixing: Through the rotation of the drum and the internal stirring device, the feed ingredients can be evenly mixed. Easy to operate: simple structure, convenient operation, easy to master and operate. Wide adaptability: It is suitable for the livestock and poultry breeding industry and can handle feed materials of different compositions and forms. |

Efficient and fast: The feed ingredients are mixed through the rotation of the spiral blades. The mixing efficiency is high and the mixing process can be completed quickly. Simple structure: Simple structure, convenient operation, easy maintenance and cleaning. Strong adaptability: suitable for mixing granular feed ingredients. |

Uniform mixing: Use the rotation and stirring action of the paddle to evenly mix the feed ingredients. Simple structure: Simple structure, convenient operation, easy maintenance and cleaning. Wide adaptability: suitable for mixing granular and powdered feed ingredients. |

Uniform mixing: It has two horizontal shafts and mixing blades, which can fully mix the feed ingredients in the horizontal direction to ensure the uniformity of the feed. Efficient and fast: The rotation of the double-shaft mixing blades makes the mixing efficiency high and the mixing process can be completed quickly. Wide adaptability: suitable for mixing granular and powdered feed ingredients. |

| Applicable industry | the livestock breeding industry and feed processing industry. | feed production industry, agriculture and animal husbandry | aquaculture industry and feed processing industry. | large farms and feed processing enterprises |

| Application field | grain, feed powder, fish meal, bone meal and other feed raw materials | ranular feed materials such as granular feed, feed pellets, and corn flour | pellet feed, powdered feed, fish feed, protein powder and other feed raw materials | granular feed, powdered feed, fish meal, corn feed and other feed raw materials |

| Model | Full volume(L) | Loading factor(L) | Production capacity(kg) | Speed(r/min) | Motor power(kw) | Swing height(mm) | Dimensions(mm) |

| VH-20 | 20L | 30% | 6 | 15 | 0.37 | 1000 | 780*450*850 |

| VH-50 | 50 | 30% | 15 | 13 | 0.55 | 1350 | 1350*500*1150 |

| VH-100 | 100 | 30% | 30 | 13 | 0.75 | 1400 | 1530*650*1200 |

| VH-200 | 200 | 30% | 60 | 13 | 1.1 | 1750 | 1750*680*1550 |

| VH-300 | 300 | 30% | 120 | 13 | 1.1 | 1980 | 2150*710*1780 |

| VH-500 | 500 | 30% | 200 | 0-13 | 2.2 | 2150 | 2300*850*1900 |

| VH-1000 | 1000 | 30% | 400 | 0-12 | 4 | 2550 | 3020*1200*2350 |

| VH-1500 | 1500 | 30% | 600 | 0-11 | 5.5 | 2650 | 3300*1400*2400 |

| VH-2000 | 2000 | 30% | 800 | 0-10 | 5.5 | 2850 | 3500*1500*2650 |

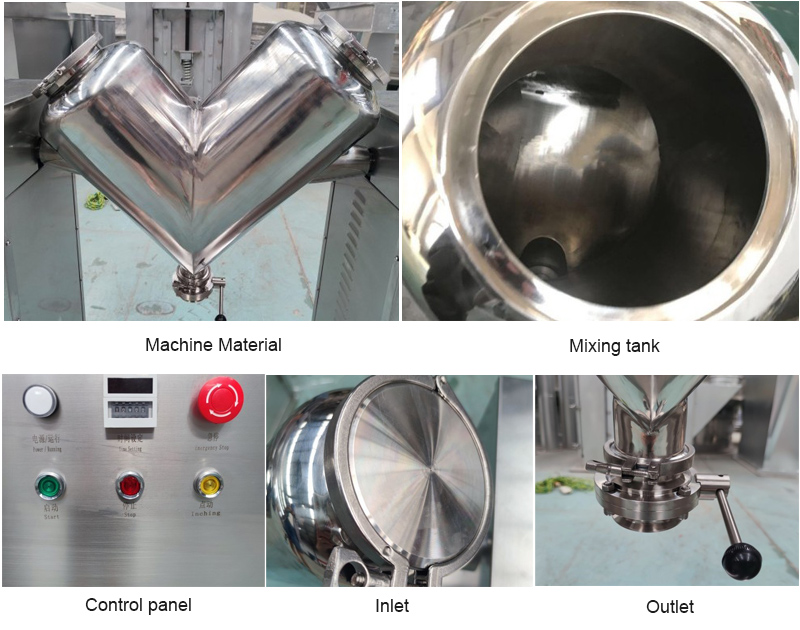

Machine Material

DZJX series V shape mixer machine is made of high quality 304 stainless steel, 316 stainless steel can be selected according to customer needs. Double feed port, feed more convenient, mix more quickly.

Mixing tank

Cylinder body wall is smooth, no dead Angle, no deposition, easy to clean. Agitator blade can be added according to customer requirements.

Control panel

The control panel is equipped with emergency stop and point switch, which is safer and easier to operate. The electronic components are all of high quality and more durable.

Inlet

Good sealing of feed port, no dust pollution.

Outlet

Discharge port can choose manual discharge or pneumatic discharge according to customer requirements, convenient and fast.

Drum feed mixers are usually made of the following main construction materials:

Stainless Steel: It is one of the materials commonly used in food and feed processing equipment. It has the advantages of corrosion resistance, easy cleaning, and high temperature resistance. It is suitable for parts that come into contact with food and feed.

Carbon Steel: Carbon steel is a common structural material used to manufacture the main structure and supporting parts of the mixer. It has good strength and durability.

Rubber: Rubber is used as a seal and shock-absorbing component of the mixer, which can effectively prevent material leakage and reduce vibration noise.

Coating Materials: The internal surface of the mixer is usually coated with special coating materials, such as polyurethane or ceramic coating, to increase wear resistance, reduce friction and extend the service life of the equipment.

Alloy Steel: Alloy steel is often used to manufacture the mixing blades and mixing shafts of the mixer. It has high strength and wear resistance and is suitable for processing various granular and powdery materials.

A livestock and poultry farm introduced a rotary drum feed mixer to solve the problems of low feed mixing efficiency and unstable feed quality. This feed mixer ensures nutritional balance and stable quality of feed through efficient mixing capabilities and stable operation. The feed production efficiency and quality of farms have been significantly improved, and the growth and health of livestock and poultry have also been improved. The rotary drum feed mixer provides a reliable feed processing solution for livestock farms.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.