Stainless steel paddle mixers can be used to mix various materials, including powders, granules, liquids, etc.

![]()

![]()

Price:$500.00-$4,500.00/Set

Consult now and enjoy a 10% discount

Mixing time: 3-4min

Each mixing amount: 300-3000kg

Capacity: Up to 1000 Liter

Orientation: Horizontal

Application: It is widely used in food processing, chemical industry, pharmaceuticals, metallurgy, environmental protection and other fields. It can be used to mix food raw materials, chemical products, pharmaceutical formulas, coatings, adhesives, pigments and other materials.

Commitment: 1Free Shipping/5 Days Delivery/30-Day Returns/Support Customization

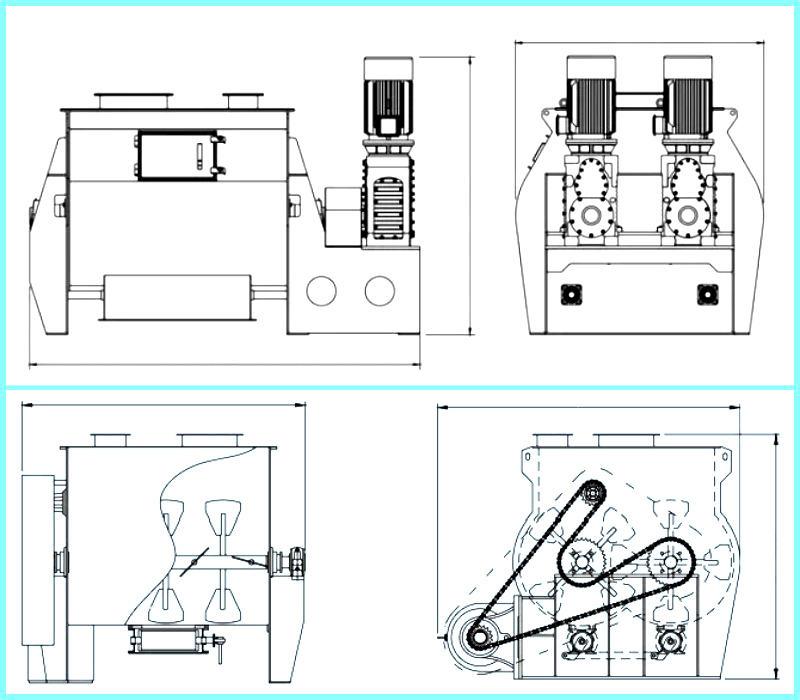

Stainless steel paddle mixer is made of stainless steel, stainless steel paddle mixer is suitable use for powder and powder, granule and granule or add a little liquid to mixing. It is widely applied in nuts, beans, feed or other kinds of granule material, inside of the machine have different angle of blade thrown up the material thus cross mixing. The barrel is equipped with two paddles that rotate in opposite directions. The strong reverse speed can shorten the mixing time, and the critical parabolic speed can make the materials evenly mixed.

This series machine overcomes the drawback of horizontal mixer to clean up inconveniently. The gear reducer and mixer rotor are direct transmission, higher reliability and longer service life. It has the advantages of corrosion resistance and easy cleaning.

Stainless steel paddle mixer is a common mixing equipment suitable for multiple industries and application scenarios. The following are some application scenarios described in detail:

Food processing: In the food industry, stainless steel paddle mixers are widely used to mix flour, condiments, sauces, jams, cake batter and other food raw materials. It can evenly mix food materials with different ingredients to ensure the consistency of product quality and taste.

Chemical industry: Stainless steel paddle mixers play an important role in the chemical industry. It can be used to mix chemical raw materials, coatings, adhesives, pigments, dyes, cosmetics and other chemical products. The mixer's efficient mixing capability ensures that various ingredients are fully mixed, improving production efficiency and product quality.

Pharmaceutical industry:In the pharmaceutical field, stainless steel paddle mixers are used to mix pharmaceutical raw materials, pharmaceutical formulas, preparations, granules, capsules and other pharmaceutical products. It enables uniform mixing and homogenization, ensuring drug stability and consistency.

Metallurgical industry: Stainless steel paddle mixers are used in the metallurgical industry to mix ores, metallurgical raw materials, smelting agents, alloys and other metallurgical materials. It can evenly mix materials with different components to meet the requirements of metallurgical processes.

Environmental protection industry: Stainless steel paddle mixers play an important role in the field of environmental protection. It can be used to mix wastewater treatment chemicals, sludge, solid waste and other environmentally friendly materials. Through mixing, waste treatment efficiency and environmental protection effects can be improved.

Scientific research and laboratories: Stainless steel paddle mixers are also widely used in scientific research institutions and laboratories. It is used to mix experimental samples, reagents, solutions and other scientific research materials to support the conduct of experiments and research work.

High safety

Made of SUS304 stainless steel, it will not contaminate the mixed materials and complies with food and drug hygiene standards.

Good mixing effect

low mixing speed, soft, smooth operation, no separation; high uniformity (CV≤3-5%).

Easy operation

The stainless steel paddle mixer is easy and convenient to operate. Just add the materials into the mixer, start the equipment and start mixing.

Large mixing volume

The effective mixing volume is increased, the filling coefficient variable range is large, and the effective volume and filling volume are increased by 40% compared with similar models.

Short mixing time

Compared with other mixing equipment, the stainless steel paddle mixer has a short mixing time (3-5 minutes) and fast discharging.

High mixing uniformity

For materials with large physical differences in specific gravity, particle size, shape, etc., segregation is less likely to occur during the mixing process.

The working principle of the stainless steel paddle mixer is to drive the paddles to rotate through an electric motor to generate powerful mixing force. The materials are driven by the paddles and circulated along the mixing tank or mixing cylinder inside the mixer to achieve mixing and uniform dispersion of the materials.

The main difference between a stainless steel paddle mixer and a carbon steel paddle mixer is the material used. It should be noted that the choice of mixer should be determined based on the specific application scenario and material characteristics. For some industries with special requirements, such as food, pharmaceuticals, etc., stainless steel paddle mixers are often the more common and recommended choice.

| Comparative Item | Stainless steel paddle mixer | Carbon steel paddle mixer |

| Material | The stainless steel paddle mixer is made of stainless steel, which is corrosion-resistant, can resist the erosion of chemical substances, and is easy to clean. | Carbon steel paddle mixers are made of carbon steel and are relatively non-corrosive. |

| Durability | Since stainless steel has good corrosion resistance, it can be used in some special environments, such as scenes where highly corrosive substances are used in the chemical industry. | Carbon steel is a strong material that can withstand large forces and pressures. It can maintain good performance in long-term use. |

| Scope of application | Due to differences in materials, stainless steel paddle mixers are more suitable for processing materials in the food, pharmaceutical, chemical and other industries, especially in scenarios with high hygiene requirements. | Carbon steel paddle mixers are more suitable for mixing needs in some general industrial fields. |

| Model | Volume(m³) | One-time mixing(kg) | Motor power(kw) | Weight |

| WZL-1 | 1 | 300-500 | 7.5-11 | 1600 |

| WZL-2 | 2 | 600-1000 | 11-15 | 2300 |

| WZL-3 | 3 | 1000-1500 | 18.5-22 | 2900 |

| WZL-4 | 4 | 1200-2000 | 22-30 | 4800 |

| WZL-5 | 5 | 1800-3000 | 30-37 | 6000 |

1. Choose the batch working capacity from 300kg to 3000kg, select mixer accordingly.

2. Choose raw material for the part contact with raw material, non-contact with raw material, other parts like motor and reducer,bearing material can not be chosen; According to the material to be mixed, processing condition, health level, raw material can be chosen from sus304, sus316L, sus321; And choose the surface treatment according to the raw material.

3. Motor power is chosen according to the material gravity, fluidity, and operation.

Operation is divided as: Start mixer when it is empty (normal duty); Start mixer with load (heavy duty)

4. Adding the auxiliary components like spraying, heating and cooling according to processing condition.

5. Mixer inlets: Feeding ports, cleaning port, vent.

6. Chose discharging and driven mode: Manual, pneumatic and electric.

Note: mixer selection is a very important step, your detailed material information, processing and factory arrangement is very helpful to get professional technical support from us.

Xinxiang Dahan stainless steel paddle mixer manufacturer is a manufacturer specializing in the production of stainless steel paddle mixers. As an industry-leading company, it has advanced production equipment and technical teams. The stainless steel paddle mixer produced is made of high-quality stainless steel materials, which is corrosion-resistant, wear-resistant and easy to clean. The product design is reasonable and the blade types are diverse, which can meet the mixing needs of different industries. Xinxiang Dahan stainless steel paddle mixer manufacturer focuses on product quality and performance and strictly implements quality control standards to ensure product stability and reliability. In addition, it also provides personalized customization services, designing and manufacturing according to customer needs. Through continuous innovation and improvement, Xinxiang Dahan stainless steel paddle mixer manufacturer is committed to providing customers with efficient and reliable stainless steel paddle mixer solutions.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.