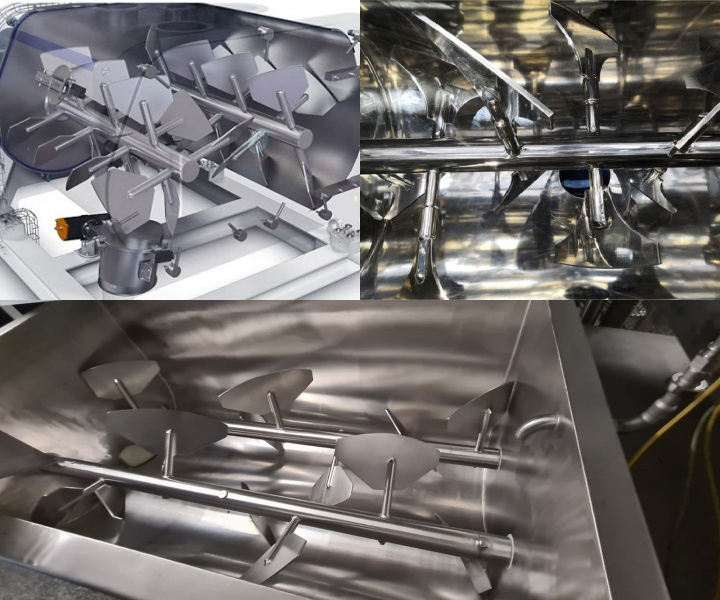

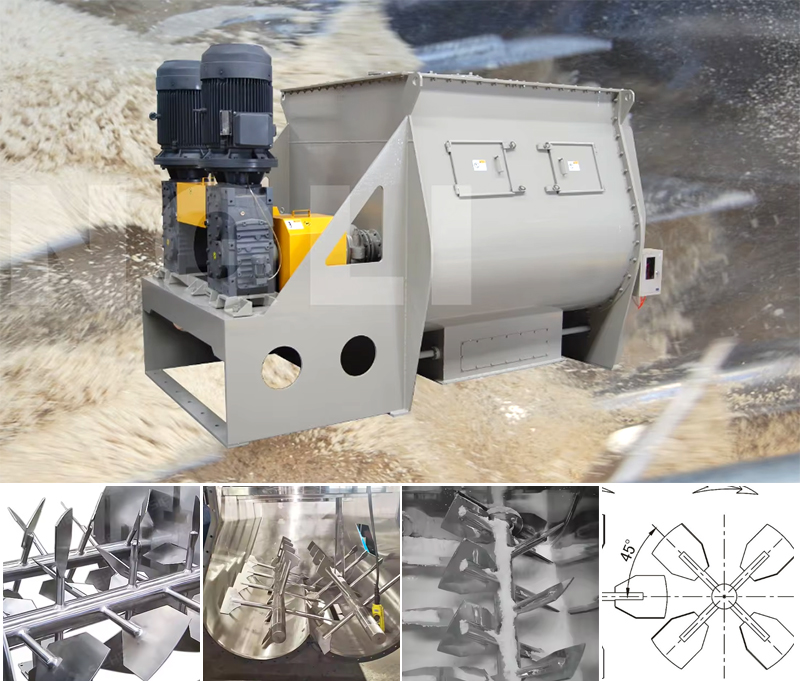

The high-speed rotating blades mix the materials evenly, improving mixing efficiency and product quality.

![]()

![]()

Price::$1000.00-$7,900.00/Set

Consult now and enjoy a 10% discount

Mixing time: 8-20min

One-time mixing: 300-3000kg (If it exceeds 3000kg, it can be customized according to needs)

Frequency: 50HZ、60HZ

Voltage: 380 Volt、Special customized 400v、 480v (Can be specially customized according to customer requirements)

Feeding method: manual feeding, automatic feeding or other methods

Discharging method: manual unloading, automatic unloading or other methods

Application: Can handle a variety of materials including powders, granules, pastes and viscous materials. They are used in industries such as food processing, pharmaceuticals, chemicals, plastics and construction.

Commitment: Free Shipping/5 Days Delivery/30-Day Returns/Support Customization

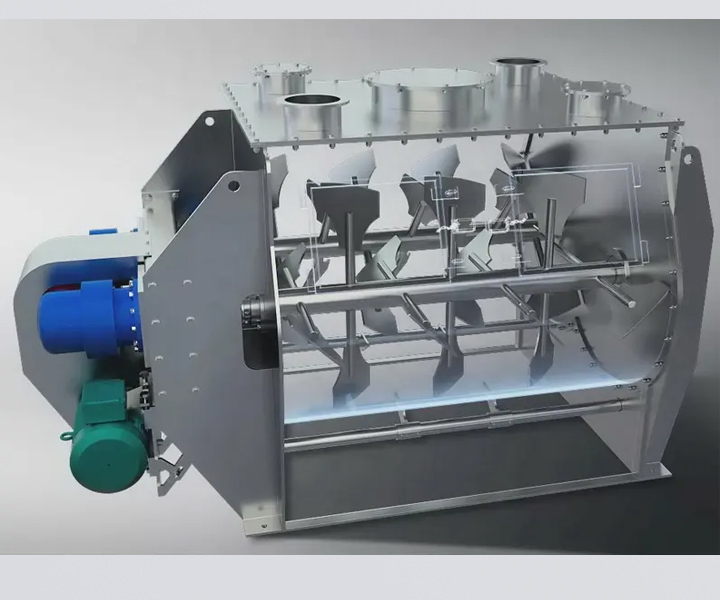

The paddle mixer is a commonly used mixing equipment used to uniformly mix different materials. It consists of one or more paddles fixed on a rotating shaft. When the mixer is started, the paddle rotates in the container and pushes the materials in different directions to achieve mixing of the materials. Paddle mixers are suitable for mixing solid, powder and granular materials.

The Paddle mixer is ideal for mixing powders, granules and pastes. It can handle a variety of materials, including dry powders, wet slurries and sticky substances, and can be customized with various features such as nozzles for adding liquids, heating or cooling jackets for temperature control, and variable speed drives for adjusting mixing intensity. It is available in batch and continuous configurations to provide flexibility in the production process.

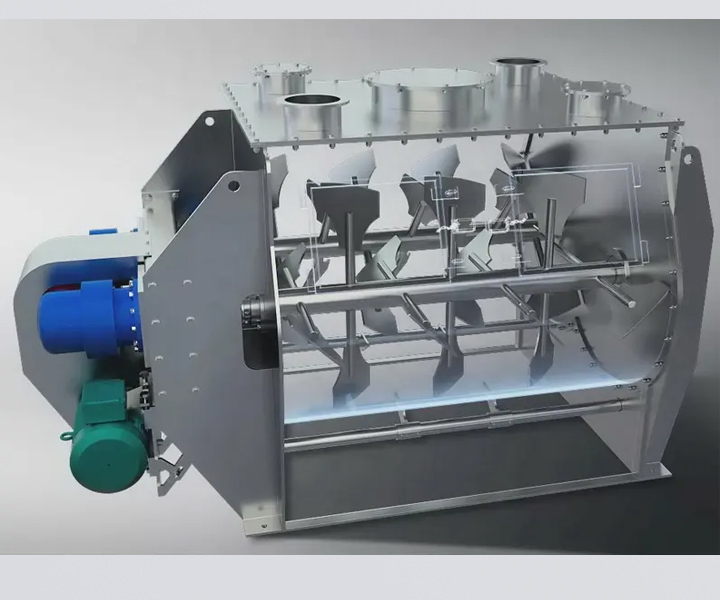

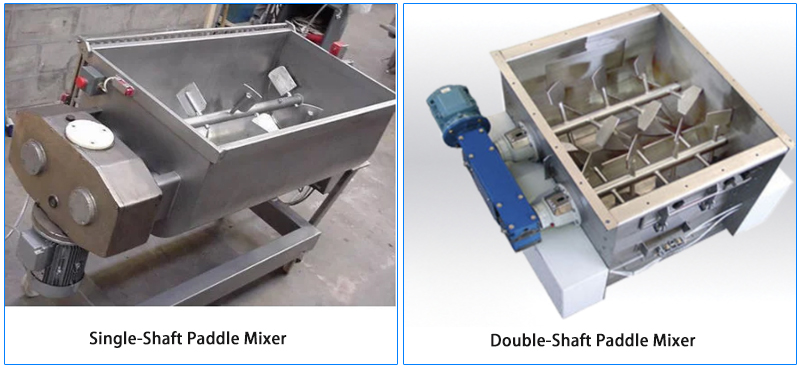

Paddle mixers can be classified into two main types: single-shaft and double-shaft paddle mixers. Here’s a brief overview of each type:

1. Single-Shaft Paddle Mixer: It has a single shaft with paddles installed on the shaft that can rotate to mix materials. It is often used to mix dry powders, granules and some liquids. It is suitable for smaller batches. Compared with double-shaft mixers, it has lower energy consumption and the mixing effect is not as uniform as double-shaft mixers.

2. Double-Shaft Paddle Mixer: It contains two parallel shafts, each equipped with paddles rotating in opposite directions. The counter-rotating paddles produce a more intense mixing action. It is suitable for large batches, heavy materials and more complex mixtures, including solids and liquids. It is more suitable for materials that are easy to agglomerate or need more thorough mixing.

In addition: Paddle mixer can be selected from carbon steel and stainless steel according to the material. Carbon steel is usually used for general dry powder and granule mixing, such as chemical and building materials industries. Stainless steel is suitable for occasions with higher requirements for hygiene and corrosion resistance, such as pharmaceutical, food and cosmetics industries, and can effectively prevent material contamination and oxidation.

Paddle mixer The gravity-free paddle mixer has multiple functions, mainly including the following aspects:

1. Solid-solid mixing: suitable for powders with a particle size of 300-2000 microns, such as uniform mixing of different drug powders, mixing of powders such as spices and seasonings, and uniform mixing of solids such as pigments and catalysts.

Chemical raw materials: uniform mixing of solids such as pigments and catalysts can effectively remove agglomerates in powders, improve mixing uniformity, ensure uniform distribution of different components in the mixture, and avoid component segregation.

2. Solid-liquid mixing: The mixer is equipped with a liquid spray port on the top for solid-liquid mixing (liquid content 15%), such as mixing solid drugs with solvents to prepare suspensions or emulsions, mixing dry powdered seasonings with water or oil to prepare sauces. It can ensure that solid particles are evenly dispersed in the liquid to avoid precipitation or stratification.

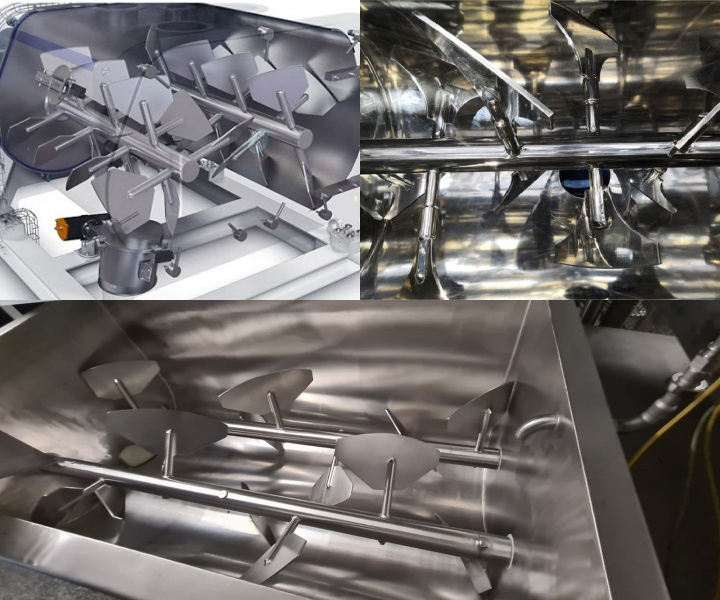

Straight blade

The straight blade is the most common type of blade. It usually consists of several straight blades and is installed on the shaft of the mixer. The straight blade can provide high mixing intensity and shearing force, and is suitable for materials that require strong mixing effect.

Inclined paddle

The paddle of the inclined paddle is installed on the shaft at an oblique angle, which can generate strong eddy current and shearing force, and is suitable for materials that require strong shearing and mixing effects.

Curved Blade

A curved blade has a curved blade, usually with a larger area and smaller angle. The curved blade can provide a larger mixing area and lower mixing shear force, and is suitable for materials that require a gentle mixing effect.

Propeller blades

The propeller blades are in a spiral shape and can generate strong eddy currents and shearing forces. They are suitable for materials that require strong shearing and stirring effects.

Special blades

According to different mixing requirements, some special-shaped blades, such as scraper blades, anchor blades, etc., can also be designed and manufactured to meet the mixing requirements of specific materials.

The paddle mixer mixes the materials through the rotation of the paddles. When working, the material is put into the mixing chamber, and then the motor is started to drive the paddle to rotate. The rotation of the paddle generates powerful stirring and shearing forces, causing the materials to be continuously cut, folded and mixed. At the same time, the rotation of the blades will also cause convection and turbulence effects, promoting uniform mixing of materials. During the mixing process, the paddle speed and mixing time can be adjusted as needed to achieve the desired mixing effect. Finally, the mixed materials can be taken out from the discharge port. The working principle of the paddle mixer is simple and effective, and it is suitable for material mixing needs in various fields.

As a type of paddle mixer, paddle mixers are widely used. The following are some common application scenarios:

Chemical industry: It can mix, dissolve, and disperse various liquid materials, such as mixing materials in reactors and mixing materials in storage tanks.

Pharmaceutical industry: It is used for mixing and batching of different types of pharmaceutical preparations, such as mixing materials in the production process of oral liquids and injections.

Food industry: It can mix and mix beverages, dairy products, and condiments in the food processing industry.

Uniform mixing

Through the rotation of the paddle, the materials are ensured to be evenly mixed to avoid unevenness.

Efficiency

Mix materials quickly, improve production efficiency, and shorten production cycle.

Wide applicability

It is suitable for mixing granular or powdery materials and can meet the needs of food, chemical, pharmaceutical and other industries.

Easy operation

It is easy to operate, easy to control and adjust the mixing process, and reduces the difficulty of operation.

Saving energy

Optimizing design saves energy consumption, reduces production costs, and improves economic benefits.

Easy maintenance

The equipment has a simple structure and is easy to clean and maintain, extending the service life of the equipment and reducing maintenance costs.

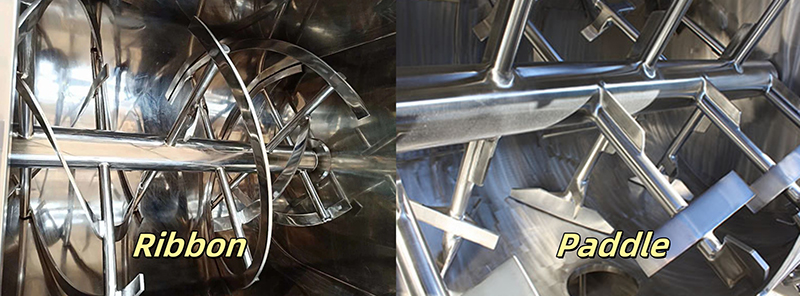

Paddle mixers and ribbon mixers are very different in many aspects such as structure and working principle. The following are the main differences.

| Feature Product | Paddle mixer | Ribbon mixer |

| Structure | Consists of a motor, gear reducer, mixing shaft, and paddles. | Consists of a motor, gear reducer, mixing shaft, and helical ribbons. |

| Working Principle | Paddles rotate to generate shear force and flow, mixing the materials. | Ribbons rotate to move materials along the axis, creating convective mixing. |

| Applicable Materials | Suitable for low-viscosity liquids, suspensions, and slurries. | Suitable for powders, granules, and high-viscosity liquids. |

| Mixing Effect | Effective for liquid materials but less effective for powdered materials. | Excellent for powdered materials, providing high mixing uniformity. |

| Energy Consumption | Relatively low. | Relatively high. |

| Applications | Used in chemical, pharmaceutical, and food industries for liquid mixing. | Used in chemical, pharmaceutical, food, and feed industries for powder mixing. |

| Model | Volume(m³) | One-time mixing(kg) | Motor power(kw) | Weight |

| WZL-1 | 1 | 300-500 | 7.5-11 | 1600 |

| WZL-2 | 2 | 600-1000 | 11-15 | 2300 |

| WZL-3 | 3 | 1000-1500 | 18.5-22 | 2900 |

| WZL-4 | 4 | 1200-2000 | 22-30 | 4800 |

| WZL-5 | 5 | 1800-3000 | 30-37 | 6000 |

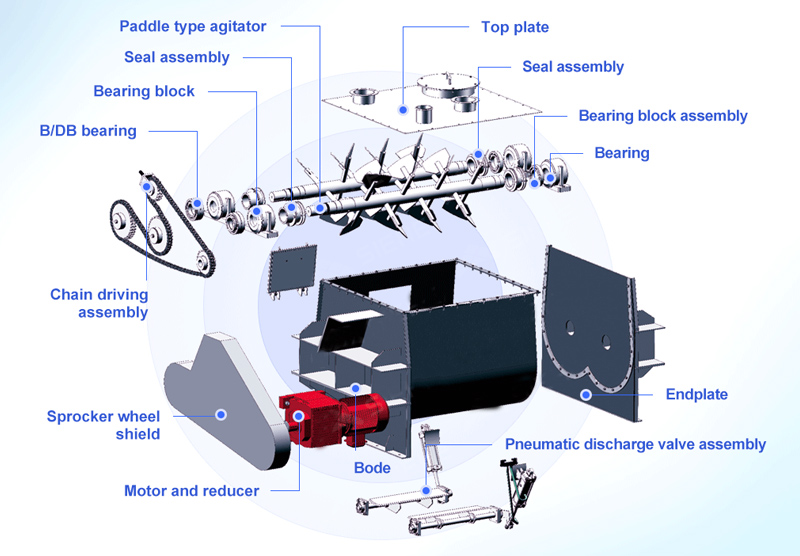

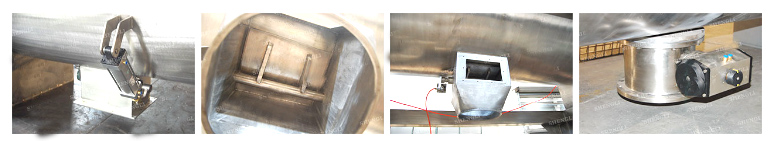

The paddle mixer consists of a mixing chamber, paddles, motor, support structure and control system. The mixing chamber is a space that accommodates the mixing of materials. The paddles are rotated by a motor, the support structure is used to support the equipment, and the control system is used to control the mixing process. These components work together to achieve uniform mixing of materials.

Mixing chamber: The mixing chamber is the space where materials are mixed. It is usually a cylindrical or elliptical cylindrical container with an inlet and outlet.

Paddle: The paddle is the core component of the paddle mixer. They are located in the mixing chamber and rotated by a motor. Blades can come in different shapes and numbers, with flat blades and curved blades being common.

Motor: The motor provides power to drive the rotation of the blades. An electric motor is usually used to drive the paddle mixer, and the power and speed of the motor can be selected according to the mixing needs.

Support structure: The support structure is used to support the mixing chamber and paddles to ensure the stability and safety of the equipment.

Control system: The control system is used to control parameters such as start and stop, speed, and running time of the paddle mixer to achieve precise control of the mixing process.

Paddle mixers are a commonly used mixing equipment that come in a variety of design and configuration options. Here are some common design elements:

Material selection: The materials of the paddle mixer can be carbon steel, manganese steel, 304 stainless steel, 316L stainless steel, 321 stainless steel, etc. According to needs, the parts in contact with the raw materials and the parts not in contact with the raw materials can be made of a combination of different materials. The surface treatment of stainless steel includes sandblasting, brushing, polishing and mirror polishing, etc., which can be used in different parts of the paddle mixer.

Drive unit: The drive device, power and speed vary according to the raw materials, starting method and processing technology. Dual-axis drive devices require synchronization capabilities, and the four different drive combinations launched by Shengli Company can meet different requirements, including two synchronous gearboxes, dual output gearboxes, dual synchronous planetary gearboxes, and combinations of reducers and chains. Among them, the SK series double synchronous gearbox is the best configuration for the double-shaft paddle mixer.

Stirring device: According to the nature of the raw materials, the paddles can be adjusted and designed accordingly. For example, wear plates, Teflon plates, or serrated paddles can be added. The twin-shaft paddle mixer can also add high-speed breaking rods inside the container to scatter the flowing material.

Discharging device: The standard discharging device of the double-shaft paddle mixer is a double pneumatic flat flap valve. When the valve is closed, the flat flap fits perfectly with the mixing barrel to avoid mixing dead zones, thus improving the mixing effect.

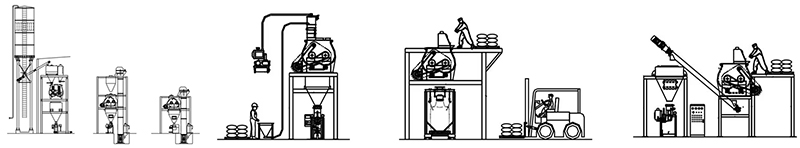

Placing in the production line, and combined with raw material silo, dosing system, conveying system, production silo, and packer,the non-gravity mixer can achieve the scale production. All equipments in the production line should be placed and coordinate with each other reasonably to realize the most efficient production.

Configuration 1: vacuum feeder, storage silo under the mixer, and a packer under silo.

Configuration 2: manually feed with the folk lift, bulk-bag packer under the mixer.

Configuration 3: manually feed, discharged to conveyed to storage silo, then packing.

When choosing a paddle mixer, you need to consider factors such as the viscosity, density, corrosiveness, etc. of the material, the purpose of mixing, the amount of mixing, and the mixing time. You can choose based on the following points.

Choosing a suitable paddle mixer requires comprehensive consideration of multiple factors to ensure that it meets the process requirements and operates efficiently. The following are key steps and considerations:

1. Determine process requirements

Mixing purpose: clarify whether it is mixing, suspending, dissolving, or reacting.

Material properties: Understand the viscosity, density, corrosiveness, etc. of the material.

2. Select the type of stirring paddle

Flat paddle: Suitable for low viscosity materials.

Inclined paddle: Suitable for medium viscosity materials.

Anchor type: Suitable for high viscosity materials to prevent sedimentation.

3. Determine the material of the equipment

Stainless steel: Suitable for corrosive materials.

Carbon steel: Suitable for non-corrosive materials.

4. Consider the sealing method

Mechanical seal: Suitable for high-demand occasions.

Packing seal: Suitable for general occasions.

A food processing company uses a paddle mixer to mix flour and seasonings. They found that after using the paddle mixer, the uniformity of the product was significantly improved, avoiding quality problems caused by uneven raw materials. At the same time, the mixing time is greatly shortened and production efficiency is improved. This enables companies to better meet market demands and improve competitiveness.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.