Ribbon Mixer For Instant Food Additives is a device specially used for mixing instant food additives (such as milk powder, coffee powder, seasoning powder, etc.). It adopts a unique ribbon stirring structure, which can evenly mix a variety of powders or powders with liquids in a short time, and is an indispensable key equipment in the food industry.

Ribbon mixer for instant food additives is an efficient and reliable equipment specially used for the mixing process of additive powders. It uses advanced technology and design to evenly mix different types of powder and granular additives to improve the quality and taste of the product.

Instant noodle production: Ribbon mixer for instant food additives can be used to mix seasoning powder, spices, food additives, etc. to ensure even distribution of seasonings and provide uniform taste and texture.

Instant rice production: In the production process of instant rice, ribbon mixer for instant food additives can be used to mix seasonings, vegetable powders, sauces, etc., so that the rice has rich taste and color.

Instant soup production: Instant soup usually requires mixing a variety of seasonings and powders. Ribbon mixer for instant food additives can evenly mix these materials to provide consistent taste and texture.

Convenient breakfast food production: For example, products such as breakfast cereals and oatmeal need to mix various cereals, dried fruits, honey and other ingredients. The ribbon mixer can ensure uniform mixing and provide rich taste and nutrition.

Convenient condiment production: Ribbon mixer for instant food additives can be used to mix various condiment powders, such as chicken essence, soy sauce powder, chili powder, etc., to make them evenly distributed and enhance the seasoning effect.

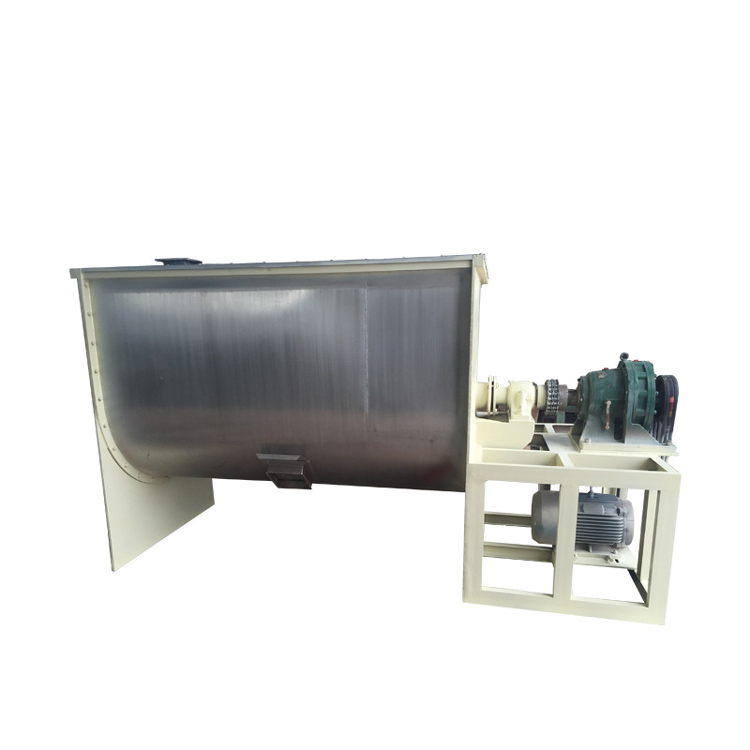

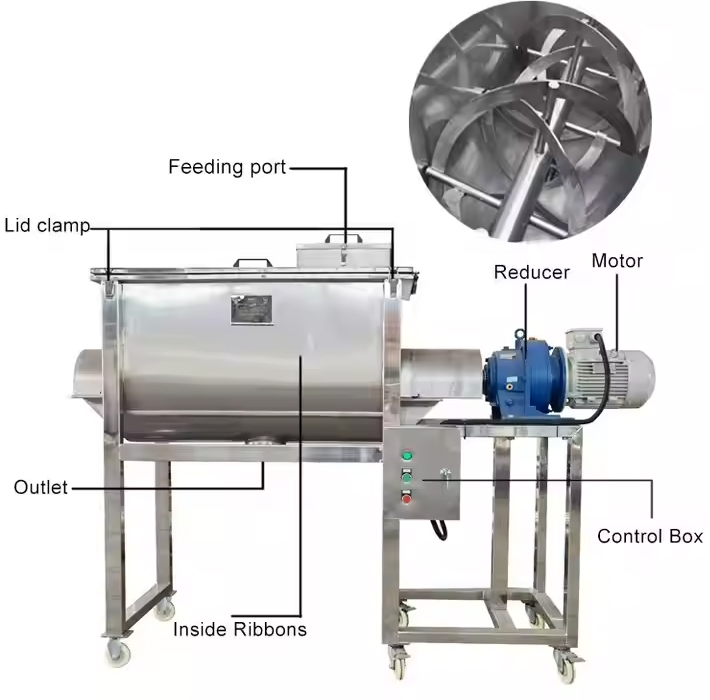

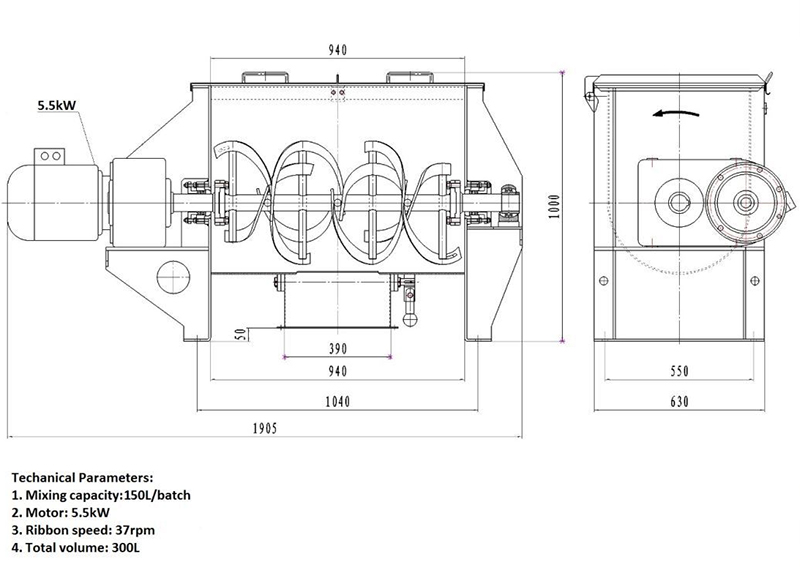

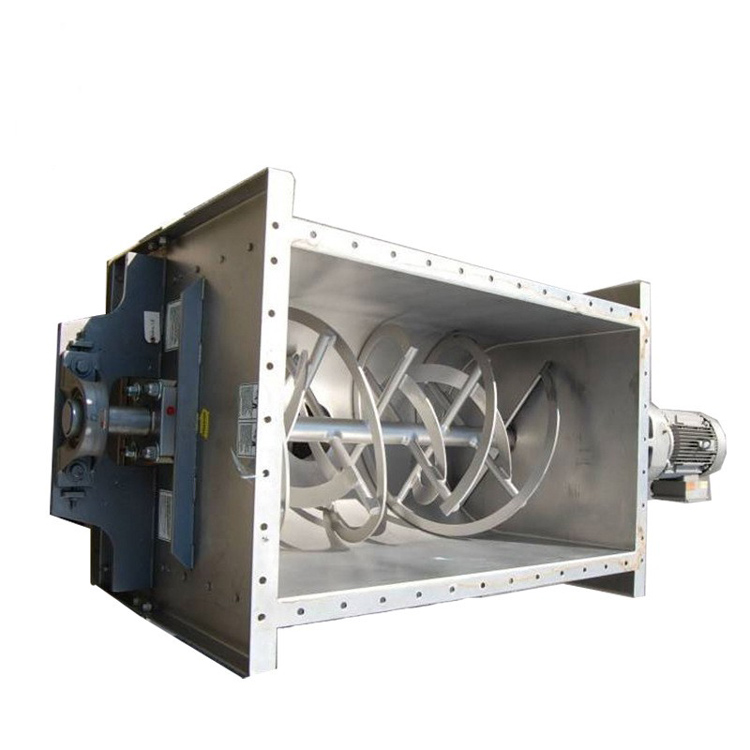

The equipment is mainly composed of a cylinder, a spiral agitator, a transmission device and an electronic control system.

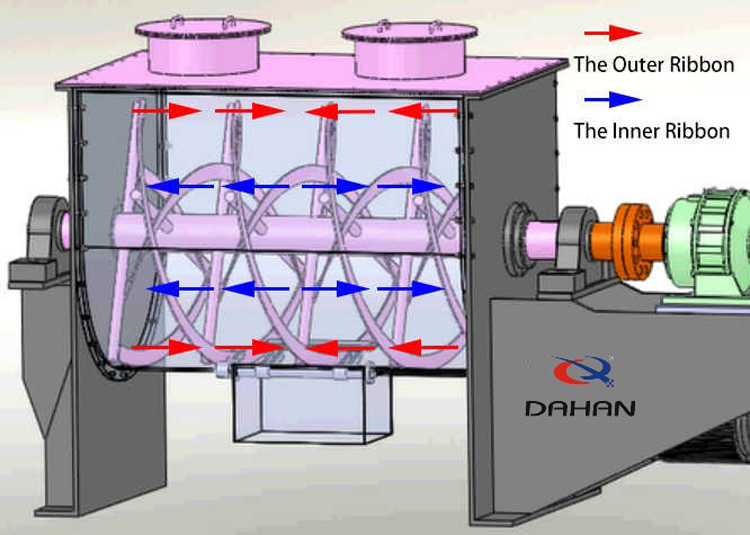

First, put the additive powder to be mixed into the cylinder through the feed port. Then, start the equipment, and the transmission device drives the spiral mixer to rotate. The design of the spiral mixer enables it to push and turn the additive powder along the axial and circumferential directions of the cylinder, thereby achieving uniform mixing of the powder. During the mixing process, friction and shearing occur between the additive powder and the stirrer and the cylinder wall, making the contact between the powder particles more complete, thereby achieving the purpose of mixing. After mixing is completed, open the discharge port and take out the mixed additive powder. The entire mixing process can be controlled and monitored through an electronic control system to ensure mixing time, speed and quality.

Stirring device: The core stirring component of the ribbon mixer consists of two layers of inner and outer ribbons. The inner ribbon is usually left-handed, which can push the material from the center of the mixer to both ends; the outer ribbon is right-handed, responsible for gathering the material from both ends to the center.

Mixing cylinder: The mixing cylinder is U-shaped or trough-shaped, providing ample space for material mixing. The inside of the cylinder is finely polished and has a smooth surface, which is convenient for the flow and cleaning of materials and effectively avoids material residue and cross contamination.

Drive system: The drive system is usually composed of a motor, a reducer, and a coupling.

Inlet and outlet device: The feed port is generally set at the top of the mixing cylinder to facilitate the input of various additives and raw materials. The outlet is located at the bottom of the cylinder and adopts a special valve design to quickly and smoothly discharge the mixed materials.

| Model | LHY-0.25 | LHY-0.5 | LHY-1 | LHY-1.5 | LHY-2 | LHY-3 | LHY-4 | LHY-6 | LHY-8 | LHY-10 |

| One-time mixing (kg) | 100-150 | 200-300 | 400-600 | 600-900 | 800-1000 | 1200-1800 | 1600-2400 | 2400-3600 | 3200-4800 | 4000-6000 |

| Mixing time (min) | 8-20 | 8-20 | 8-20 | 8-20 | 8-20 | 8-20 | 8-20 | 8-20 | 8-20 | 8-20 |

| Mixing speed (r/min) | 60 | 55 | 45 | 40 | 35 | 25 | 25 | 20 | 15 | 15 |

| Motor power (kw) | 3-5.5 | 4-11 | 7.5-15 | 11-18.5 | 15-22 | 18.5-30 | 22-37 | 37-55 | 37-55 | 45-75 |

| Weight (kg) | 500 | 900 | 1800 | 2500 | 3200 | 4100 | 5100 | 6300 | 7500 |

Efficient performance: Ribbon mixer for instant food additives adopts a spiral mixer and cylinder structure, which can quickly and evenly mix additive powders and improve production efficiency.

Uniform mixing: The design of the mixer enables the additive powder to fully contact and disperse during the mixing process, achieving uniform mixing and ensuring product consistency.

Energy saving: The mixer design of the Ribbon mixer for instant food additives results in lower energy consumption during the mixing process, saving energy costs.

Easy operation: The operator only needs to put the additive powder into the feed port, set the mixing time and speed, and then start the equipment. The operation is simple and convenient.

Easy to clean and maintain: The barrel and mixer of Ribbon mixer for instant food additives are made of stainless steel, which is easy to clean and meets food hygiene requirements. At the same time, the maintenance of the equipment is relatively simple.

Reliability and durability: Ribbon mixer for instant food additives uses high-quality materials and strict manufacturing processes, has high reliability and durability, and can run stably for a long time.

All in all, ribbon mixer for instant food additives is an indispensable tool in modern food production. It provides reliable mixing solutions for food production companies with its advantages of efficient performance, uniform mixing, energy saving, simple operation, easy cleaning and maintenance. Whether it is to improve product quality, improve taste, or meet market demand, ribbon mixer for instant food additives can become a powerful assistant for food production companies.

Instant food additive ribbon mixers are key equipment for mixing powder, granular or liquid materials in the food industry. In order to ensure that the equipment can operate efficiently and stably and meet production needs, selection and use maintenance are essential.

Capacity selection

Small production or laboratory: You can choose equipment with a smaller capacity (such as 100L, 200L, 500L).

Medium-sized production: It is suitable to choose equipment with a capacity of 500L-1000L.

Large-scale production: It is recommended to choose equipment with a capacity of 1000L-2000L or larger.

Consider material characteristics:

For materials with lighter specific gravity (such as milk powder, coffee powder), you can choose a slightly larger capacity equipment to improve efficiency.

For materials with larger specific gravity (such as seasoning powder, nutritional supplements), you need to choose the appropriate capacity according to actual needs.

Material selection

Food grade stainless steel:

304 stainless steel: Suitable for mixing most food additives, with good corrosion resistance and hygiene.

316L stainless steel: suitable for materials with high corrosiveness or high hygiene requirements (such as acidic seasoning powder, pharmaceutical raw materials).

Additional functions

Heating function: suitable for materials that need to be heated and mixed (such as chocolate powder, oil additives).

Cooling function: suitable for materials that need to be cooled and mixed (such as heat-sensitive food additives).

Vacuum function: suitable for materials that are easily oxidized or need to be degassed (such as nutritional supplements, health foods).

Address:China,Yanjin county forest park gate to the west 1000 meters north road.