Used in the feed processing industry to mix and evenly distribute various feed raw materials and pelleted feed ingredients

![]()

![]()

Price:$500.00-$4,500.00/Set

Consult now and enjoy a 10% discount

Capacity: 500L-9000L

Production time: 10-15 seconds

Work efficiency: 12 batches of work per hour, fully automatic

Orientation: Horizontal

Weight: 1600kg-6000kg

Application: It can be used to mix various pelleted feed ingredients, including grains, soybean meal, fish meal, protein powder, vitamins, minerals, etc.

Commitment: Free Shipping/5 Days Delivery/30-Day Returns/Support Customization

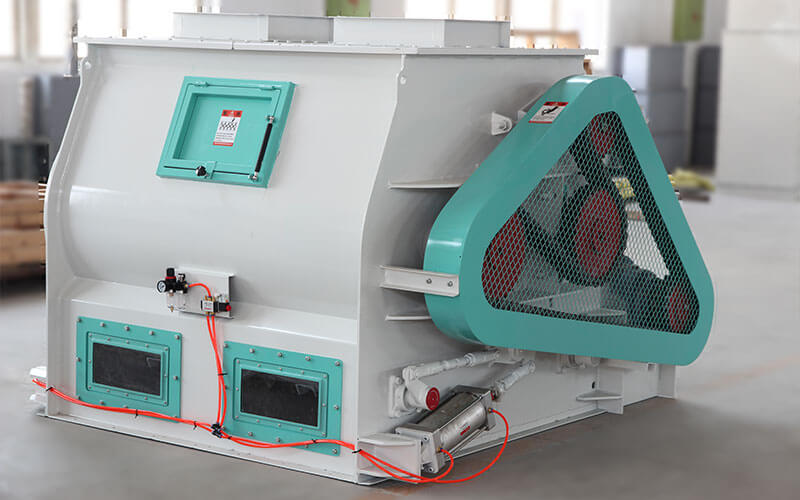

Double Shaft Paddle Feed Mixer is a mixing equipment specially used in the feed processing industry. It consists of two rotating shafts and multiple paddles, and is used to uniformly mix different types of feed ingredients. Double shaft paddle feed mixer is mainly made of carbon steel and adopts a horizontal design.

The first feature of this mixer is the double shaft design. Through the two rotating shafts, the feed ingredients can be fully turned and stirred in the mixer to achieve better mixing effects. Secondly, the blade design of the double shaft blade feed mixer is also very important. The shape and arrangement of the paddles can affect the mixing effect.

The common types of blades in feed hybrid are:

Paddle

A paddle is a common type of blade, usually in the shape of a paddle, used for stirring and mixing feed ingredients. It can push feed ingredients to the mixing area to achieve uniform mixing and ensure even distribution of various ingredients in the feed.

Spiral blades

The spiral blades are in a spiral shape and can effectively propel and mix feed ingredients. It can generate strong shearing and propulsion forces, allowing the feed ingredients to rotate and move quickly in the mixing chamber to achieve better mixing effects.

Blade

Blades are usually used for cutting and mixing feed ingredients and have strong cutting and crushing capabilities. It is able to cut larger feed particles into smaller particles, making them easier to mix and digest.

Mixing blade

The mixing blade is used to stir and mix feed ingredients, and can evenly mix particles of different ingredients. It can push the feed ingredients to the mixing area and mix them thoroughly through the stirring motion to ensure the uniformity of the feed.

Curved blades

Curved blades are curved or twisted in shape, which can effectively push feed ingredients to the mixing area to achieve uniform mixing. It can generate large stirring force and shearing force to promote the mixing and uniformity of feed ingredients.

V-shaped blade

The shape of the V-shaped blade is similar to the letter "V", which can provide a larger mixing area and promote the mixing and uniformity of feed ingredients. It can push feed ingredients to the mixing area and mix them thoroughly through stirring motion.

The double shaft paddle feed mixer is a common feed mixing equipment. Its working principle is as follows:

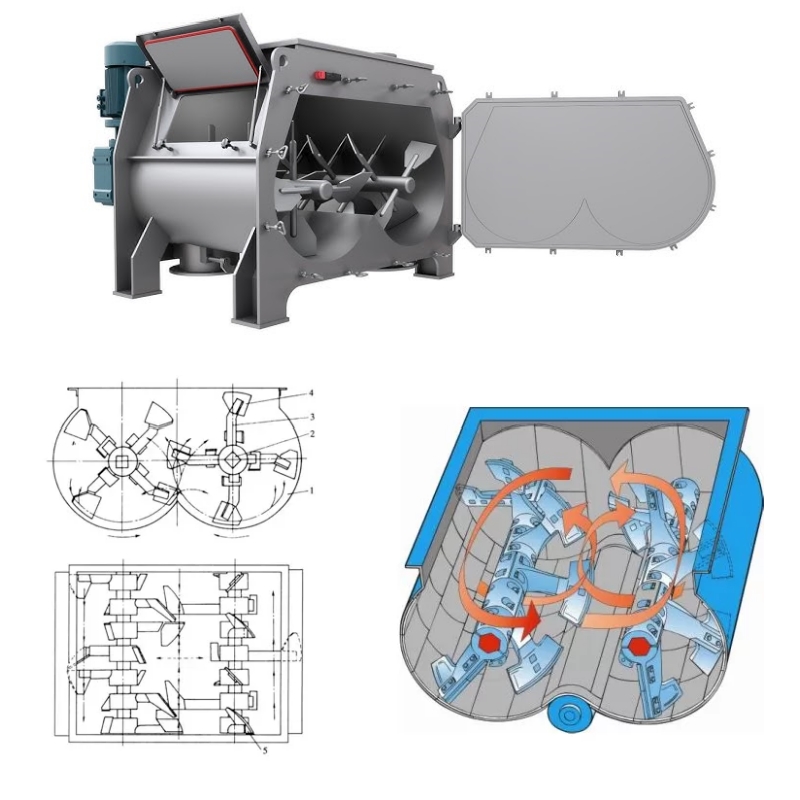

Structure: Double shaft paddle feed mixers usually consist of two parallel main shafts, with paddles installed on each main shaft. The two spindles are parallel and staggered to form a mixing chamber.

Mixing process: When the mixer starts, the main shaft begins to rotate at high speed. The rotation of the paddle generates strong centrifugal force and shear force, pushing the feed ingredients to the surroundings of the mixing chamber.

Reverse movement: Due to the relative movement of the two spindles, the feed ingredients continuously move up and down, left and right in the mixing chamber. This reverse movement allows the feed ingredients to fully contact and mix, thereby achieving a uniform mixing effect.

Mixing time: Mixing time is usually set according to the nature and requirements of the feed. During the mixing process, the feed ingredients undergo multiple reverse movements and paddle stirring to gradually achieve uniform mixing.

Discharge: After the mixing is completed, the mixed feed can be taken out through the discharge port of the equipment for feeding use.

| Model | Volume(m³) | One-time mixing(kg) | Motor power(kw) | Weight(kg) |

| WZL-1 | 1 | 300-500 | 7.5-11 | 1600 |

| WZL-2 | 2 | 600-1000 | 11-15 | 2300 |

| WZL-3 | 3 | 1000-1500 | 18.5-22 | 2900 |

| WZL-4 | 4 | 1200-2000 | 22-30 | 4800 |

| WZL-5 | 5 | 1800-3000 | 30-37 | 6000 |

The double shaft paddle feed mixer is an efficient mixing equipment suitable for a variety of feed mixing scenarios. Its application scenarios include but are not limited to the following aspects:

Feed processing industry: The double shaft paddle feed mixer is one of the common equipment in the feed processing process. It can be used to mix feed raw materials with different ingredients, prepare feed formulas, and improve the uniformity and nutritional value of feeds. Feed mixers are required in feed processing plants, feed ingredients plants and other industries.

Breeding industry: In the breeding industry, double shaft paddle feed mixers are widely used in poultry breeding (such as chickens, ducks, geese) and livestock breeding (such as pigs, cattle, sheep) and other fields. It can mix different types and specifications of feed ingredients together to make feed that meets the nutritional needs of animals.

Mixed fertilizer production: The double shaft paddle feed mixer can also be used in the production process of mixed fertilizer. It can evenly mix different types of fertilizer raw materials to produce compound fertilizers that meet the nutritional needs of plants.

Chemical industry: In the chemical industry, double shaft paddle feed mixers can be used to mix and stir different types of powder or granular materials. It is widely used in processes such as mixing of chemical raw materials, stirring of reactors, and preparation of granular materials.

Grain processing industry: In the grain processing industry, the double shaft paddle feed mixer can be used to mix different types of grain raw materials to produce mixed feed or processed food that meets specific requirements.

Double shaft stirring paddle, adjustable distance, higher efficiency and better stirring effect.

It is especially suitable for adding liquid mixing or granular wet particles, the size is between 0.3-3mm.

It only takes 3 minutes to mix powder and 5 minutes to mix liquid mud.

The coefficient of variation is less than 5%, which can be used to mix materials with large differences in specific gravity and particle size without stratification and segregation.

Closed operation, stable operation, low noise, low dust concentration, no pollution to theenvironment.

Adopting an automated control system, the operation is simple and convenient. Only need to set the parameters such as mixing time and speed.

| Comparative Item | Double Shaft Paddle Feed Mixer | Single Shaft Paddle Feed Mixer |

| Structural design | two shafts and blades | only one shaft and blades |

| Mixing effect | better cut, disperse and mix feed ingredients | relatively weak and is suitable for general feed mixing needs |

| Handling Capacity | handle larger batches of feed ingredients | processing capacity is relatively small. |

| Applicable materials | feed raw materials with different particle sizes and material characteristics | more suitable for general granular and powdery feed materials |

A breeding farm needs to produce high-quality feed, and they chose a twin-shaft paddle feed mixer as the mixing equipment. Because the twin-shaft paddle feed mixer has the characteristics of uniform mixing and efficient mixing, it can ensure the nutritional balance and stable quality of the feed. At the same time, the equipment’s large-capacity processing and structural stability can also meet the production needs of farms. By using a twin-shaft paddle feed mixer, this farm has successfully improved the quality of feed and met the nutritional needs of livestock and poultry.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.