strong>Apatite powder for Ribbon Mixer

is a mechanical equipment specially used for mixing apatite powder. It adopts a spiral ribbon stirring structure, with a spiral blade rotating around the central axis. It can quickly and evenly mix apatite powder with other raw materials in a closed container, playing a key role in the production process of apatite powder.

High mixing uniformity:The unique ribbon structure inside the ribbon mixer can form a complex material flow field during the rotation process. Under the action of this flow field, apatite powder can fully contact and interweave with other materials, thereby achieving a highly uniform mixing effect.

Prevent material stratification: Due to the high density of apatite powder, if ordinary mixing methods are used, stratification is prone to occur during the static process after mixing. The ribbon mixer can effectively break this stratification trend caused by density differences through continuous stirring, maintain the uniformity of the mixed materials, and ensure the stability of product quality.

High efficiency and energy saving: The design of the ribbon mixer makes it have low energy consumption during operation, and can quickly complete the task of mixing apatite powder with other materials.

Good sealing: The closed design of the ribbon mixer can avoid the flying of apatite powder during mixing.

Ribbon mixers are widely used in the following apatite powder mixing scenarios:

Phosphate fertilizer production: Apatite powder is mixed with nitrogen fertilizer, potassium fertilizer and other raw materials to produce compound fertilizers of various formulas.

Chemical raw material preparation: Apatite powder is mixed with other chemical raw materials for the production of chemical products such as phosphoric acid and phosphates.

Building material production: Apatite powder is mixed with cement, sand and gravel and other raw materials for the production of building mortar, concrete and other building materials.

When working, apatite powder and other raw materials are put into the mixing chamber in proportion, the drive device is started, and the ribbon blades begin to rotate. The outer ribbon pushes the material from both ends to the center, and the inner ribbon pushes the material from the center to both ends, while the material moves up and down under the action of gravity. Multiple movement modes work together to make the material continuously convect, shear and diffuse in the mixing chamber, and finally achieve the purpose of uniform mixing.

| Model | LHY-0.25 | LHY-0.5 | LHY-1 | LHY-1.5 | LHY-2 | LHY-3 | LHY-4 | LHY-6 | LHY-8 | LHY-10 |

| One-time mixing (kg) | 100-150 | 200-300 | 400-600 | 600-900 | 800-1000 | 1200-1800 | 1600-2400 | 2400-3600 | 3200-4800 | 4000-6000 |

| Mixing time (min) | 8-20 | 8-20 | 8-20 | 8-20 | 8-20 | 8-20 | 8-20 | 8-20 | 8-20 | 8-20 |

| Mixing speed (r/min) | 60 | 55 | 45 | 40 | 35 | 25 | 25 | 20 | 15 | 15 |

| Motor power (kw) | 3-5.5 | 4-11 | 7.5-15 | 11-18.5 | 15-22 | 18.5-30 | 22-37 | 37-55 | 37-55 | 45-75 |

| Weight (kg) | 500 | 900 | 1800 | 2500 | 3200 | 4100 | 5100 | 6300 | 7500 |

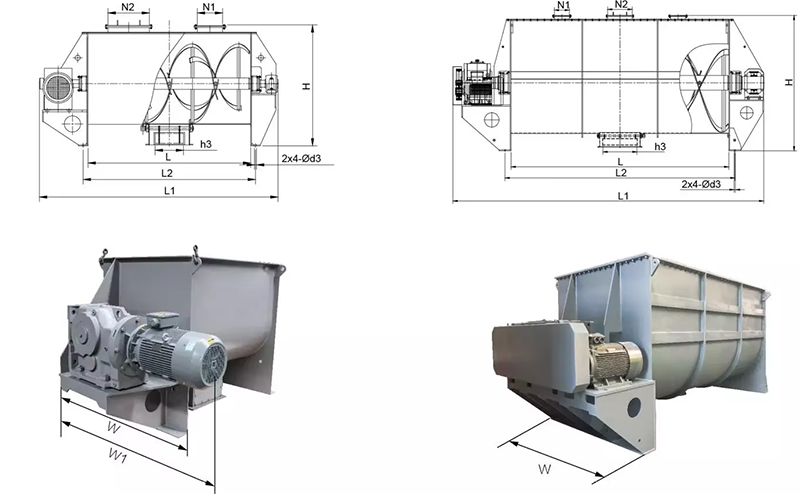

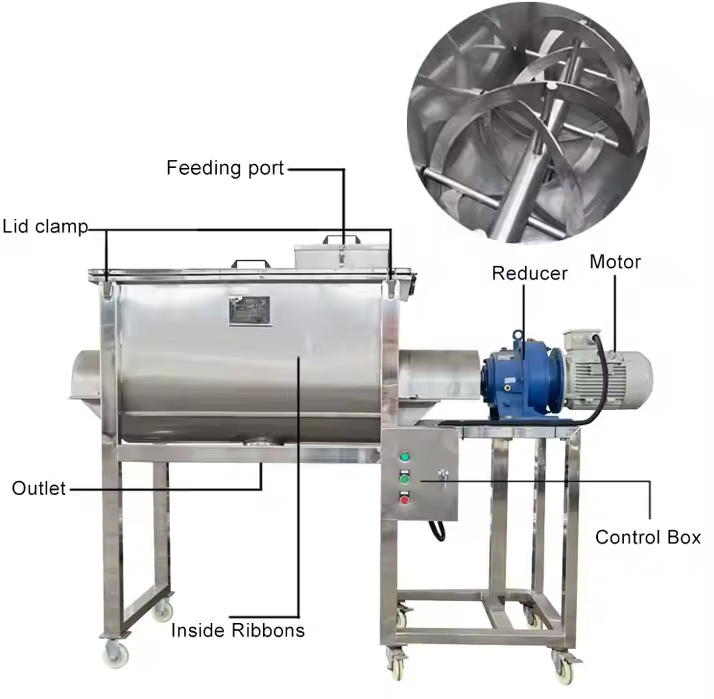

The apatite powder ribbon mixer is mainly composed of the following components:

Mixing chamber: Usually U-shaped, used to hold the materials to be mixed.

Spiral blade: It consists of two inner and outer spiral ribbons, which rotate along the inner wall and central axis of the mixing chamber respectively, and push the materials to move in multiple dimensions.

Drive device: Including motor, reducer, etc., to provide power for the ribbon blade.

Feed port and discharge port: Used for material input and discharge respectively.

Other accessories: Such as liquid spraying device, heating/cooling jacket, etc., which can be selected as needed.

Apatite powder has certain viscosity and abrasiveness, so the following requirements are put forward for the ribbon mixer:

Wear resistance: The agitator and barrel of the ribbon mixer need to have good wear resistance to extend the service life of the equipment.

Mixing uniformity: The mixing uniformity of apatite powder directly affects its application effect, so the ribbon mixer is required to achieve high uniformity mixing.

Easy to clean: The stickiness of apatite powder can easily lead to residual materials inside the equipment, so the ribbon mixer is required to be easy to clean.

Good sealing: Apatite powder is prone to generate dust during the mixing process, so the ribbon mixer is required to have good sealing to reduce dust pollution.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.