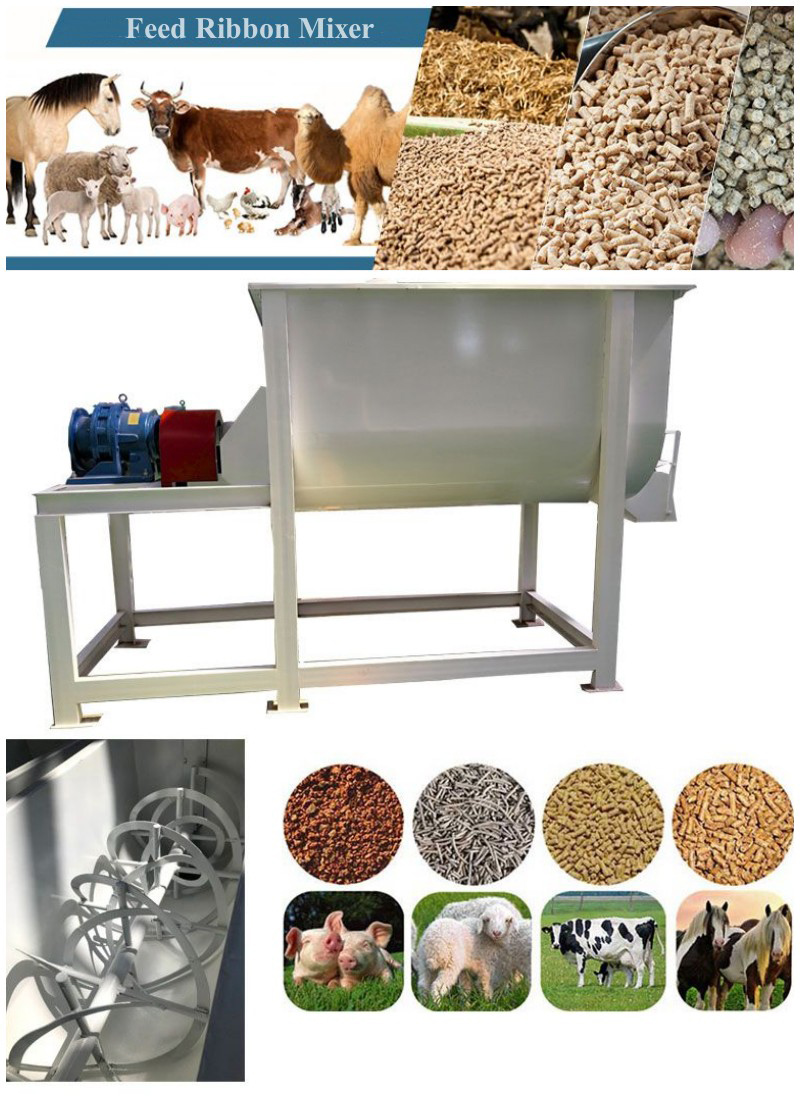

Mix feed ingredients of different compositions to achieve a homogeneous mix, from small farms to large feed mills.

![]()

![]()

Price::$300.00-$3,500.00/Set

Consult now and enjoy a 10% discount

Capacity: Up to 1000 Liter

Phase: Three Phase

Frequency (Hz): 50 Hz

Voltage: 380 Volt

One-time mixing: 100-6000 (kg)

Application: It is suitable for mixing and stirring aquaculture, poultry and fish feed pellets to ensure the uniformity and high quality of feed and meet the nutritional needs of livestock and poultry.

Commitment: Free Shipping/5 Days Delivery/30-Day Returns/Support Customization

Feed ribbon mixer is a piece of equipment used for feed processing. It is mainly used to mix and stir different types of feed raw materials to obtain uniform distribution and improve feed quality. It adopts a ribbon-type mixing structure. Through the rotation and pushing of the spiral ribbon, the feed raw materials are fully mixed to ensure the uniformity of various ingredients and improve the solubility and digestibility of the feed.

Feed ribbon mixer is suitable for various types of feed processing. Whether it is the production of aquaculture, poultry or fish feed pellets, the feed ribbon mixer can do the job. It can handle feed ingredients of different particle sizes and shapes, including powders, granules and solids. By adjusting the mixing time and speed, the mixing requirements of different types of feed can be met and the uniform distribution of various ingredients in the feed can be ensured.

The feed ribbon mixer realizes the mixing and stirring of feed raw materials through the rotation and pushing of the spiral ribbon. When the machine is started, the spiral ribbon begins to rotate, pushing the feed ingredients from one end to the other. The design of the spiral ribbon allows the feed ingredients to form a continuous circulation flow inside the machine, prompting the feed ingredients of different ingredients to flip and cross. In this way, the feed ingredients are thoroughly mixed together and evenly distributed. The feed ribbon mixer can also adjust the mixing time and speed as needed to meet the mixing requirements of different feeds. Its working principle is simple and efficient, and can improve the quality and solubility of feed. Feed ribbon mixers play an important role in the feed processing industry and provide reliable solutions for the production of high-quality feed.

Short mixing time

Usually each batch of materials is mixed in 8-20 minutes to achieve full mixing and stirring, which is 6-10 times more efficient than other mixers.

Safe and convenient

304 stainless steel is used for material contact parts, with good finish, convenient operation and maintenance, and meets food-grade hygiene requirements.

High mixing uniformity

The optimally designed two-way spiral-belt rotor has mild mixing process, high uniformity and no segregation.

Multifunctional mixing device

The inner and outer two-layer spiral belt has a unique structure, runs smoothly, and has a variety of agitator structures, it is a multifunctional mixing device.

High mixing efficiency

The ribbon mixer is reasonably designed and has fast mixing speed. It can quickly mix feed ingredients, improve production efficiency, and save time and labor costs.

Energy saving

Using an efficient power transmission system can reduce energy consumption and improve energy utilization efficiency. It also features low noise and low vibration.

| Model | LHY-0.25 | LHY-0.5 | LHY-1 | LHY-1.5 | LHY-2 | LHY-3 | LHY-4 | LHY-6 | LHY-8 | LHY-10 |

| One-time mixing (kg) | 100-150 | 200-300 | 400-600 | 600-900 | 800-1000 | 1200-1800 | 1600-2400 | 2400-3600 | 3200-4800 | 4000-6000 |

| Mixing time (min) | 8-20 | 8-20 | 8-20 | 8-20 | 8-20 | 8-20 | 8-20 | 8-20 | 8-20 | 8-20 |

| Mixing speed (r/min) | 60 | 55 | 45 | 40 | 35 | 25 | 25 | 20 | 15 | 15 |

| Motor power (kw) | 3-5.5 | 4-11 | 7.5-15 | 11-18.5 | 15-22 | 18.5-30 | 22-37 | 37-55 | 37-55 | 45-75 |

| Weight (kg) | 500 | 900 | 1800 | 2500 | 3200 | 4100 | 5100 | 6300 | 7500 |

Feed ribbon mixer is a common equipment in the field of feed processing, and it plays an important role in different scenarios. This kind of mixer is mainly used in feed processing plants, breeding farms and feed production enterprises.

In feed processing plants, feed ribbon mixers are used to mix various feed ingredients. It can evenly mix feed ingredients with different ingredients such as grains, protein powder, vitamins, minerals, etc. to ensure the balance and consistency of the feed. This is essential for producing high quality feed.

In farms, feed ribbon mixers are used to prepare various types of feed, such as chicken feed, pig feed, cattle feed, etc. It mixes different feed ingredients evenly to ensure animals receive balanced nutrition. This is very important for the growth and health of the animal.

In feed production enterprises, feed ribbon mixers are used to add drugs, additives, pigments, etc. It can evenly mix these substances into the feed to improve the nutritional value and functionality of the feed and meet specific needs.

Feed ribbon mixers are available in a variety of options to meet different feed processing needs and production scales. Here are some common options:

Capacity selection: The capacity of the feed ribbon mixer can be selected according to production needs. There are usually different specifications to choose from, such as 100 liters, 500 liters, 1000 liters, etc. Larger production scale usually requires larger capacity mixers.

Power selection: The feed ribbon mixer can be powered by electric or diesel power. Choose the appropriate power type according to the actual situation and use environment.

Material selection: The body and mixing part of the mixer are usually made of stainless steel or carbon steel. Stainless steel is corrosion-resistant and suitable for handling feed materials with high humidity.

Control system selection: The feed ribbon mixer can choose manual control or automatic control system. The automatic control system can achieve precise control and parameter adjustment of the mixing process, improving production efficiency and mixing quality.

Selection of supporting equipment: According to actual needs, the feed ribbon mixer can choose supporting equipment, such as screw conveyor, unloader, etc., to realize an automated feed production line.

Xinxiang Dahan Mixer Factory is a manufacturer specializing in the manufacturing of mixer equipment. As a manufacturer, the manufacturer has rich experience and technology and is committed to providing customers with high-quality feed ribbon mixers.

The products produced have advanced design and manufacturing processes and use high-quality materials to ensure the stability and durability of the equipment. In addition, manufacturers also provide customized services and provide personalized solutions according to customer needs and requirements. Xinxiang Dahan Factory has won widespread market recognition and trust for its reliable products and high-quality services.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.