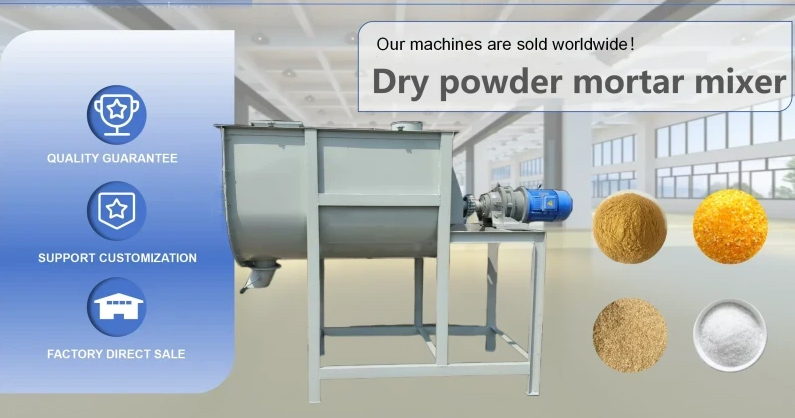

Can be used to mix dry sand, cement, gypsum powder, lime powder and other dry powder raw materials

![]()

![]()

Price:$500.00-$5,000.00/Set

Consult now and enjoy a 10% discount

Capacity: Up to 1000 Liter

Frequency (Hz): 50 Hz

Voltage: 380 Volt

Mixing time of mixer: 3-5min / batch

One-time mixing: 100-6000 (kg)

Application: Dry powder mortar mixers are widely used in the construction industry and engineering fields. It is mainly used to mix various dry powder materials, such as cement, gypsum, lime, sand, etc.

Commitment: Free Shipping/5 Days Delivery/30-Day Returns/Support Customization

Dry powder mortar mixer is a kind of equipment specially used for mixing dry powder materials and is widely used in the construction industry and engineering fields. Its main function is to fully mix dry powder raw materials such as cement, gypsum, lime, and sand to prepare building materials such as mortar, putty, and tile adhesive.

Dry powder mortar mixer has efficient mixing capabilities, thanks to its professionally designed mixing device. In addition, the dry powder mortar mixer has flexible operation and maintenance features. It is usually equipped with a simple and easy-to-understand operating interface, allowing users to conveniently operate and control the equipment. Dry powder mortar mixers are also available in a variety of models and specifications. According to different production needs and scale, users can choose suitable mixer models and specifications. This ensures the best match of production efficiency and product quality to meet the needs of various construction projects.

Type 1: Double Shaft Paddle Dry Powder Mortar Mixer

Working principle: The double shaft paddle dry powder mortar mixer fully mixes the dry powder mortar raw materials through the rotation of the double shaft paddles. The paddle design allows the raw materials to be continuously stirred and turned in the mixing chamber to achieve a uniform mixing effect.

Advantages: Good mixing effect, which can fully mix the dry powder mortar raw materials. Easy operation, easy control system operation. Stable structure, wear-resistant and durable, suitable for long-term use.

Type 2: Ribbon Dry Powder Mortar Mixer

Working principle: The ribbon dry powder mortar mixer effectively mixes the dry mortar raw materials through the rotation of the spiral ribbon. The spiral ribbon design allows the raw materials to be continuously stirred and turned in the mixing chamber to achieve a uniform mixing effect.

Advantages: Excellent mixing effect, ensuring uniform mixing of dry mortar raw materials. Easy operation, convenient parameter setting. Compact structure, small footprint, suitable for production and use in limited space.

Selection suggestions:

For production that requires fast mixing speed and good mixing effect, you can choose a double shaft paddle dry powder mortar mixer.

For production that requires uniform mixing, low noise and low energy consumption, you can choose a ribbon dry powder mortar mixer.

In addition, it is also necessary to consider the capacity, power, material, price and other factors of the mixer for comprehensive consideration.

Adding materials: Add dry powder mortar raw materials (such as sand, cement, additives, etc.) into the hopper or feed port of the mixer according to a certain proportion.

Mixing: After starting the mixer, depending on the type of equipment, the mixing blades inside the mixer begin to rotate or cut, and the dry powder raw materials are stirred, sheared, thrown and other actions to fully mix them.

Mixing time: Set a certain mixing time according to the mortar formula and mixing requirements to ensure that the dry powder raw materials are fully mixed evenly.

Discharge: After mixing is completed, open the discharge port of the mixer and discharge the mixed mortar materials.

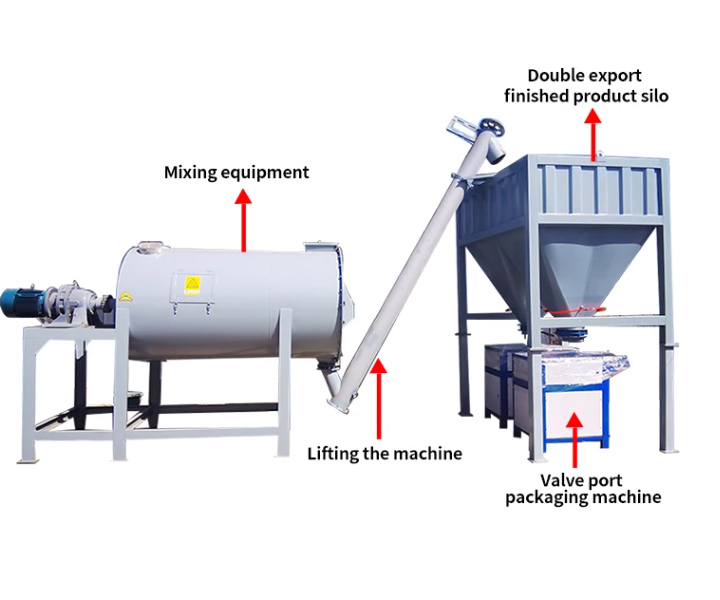

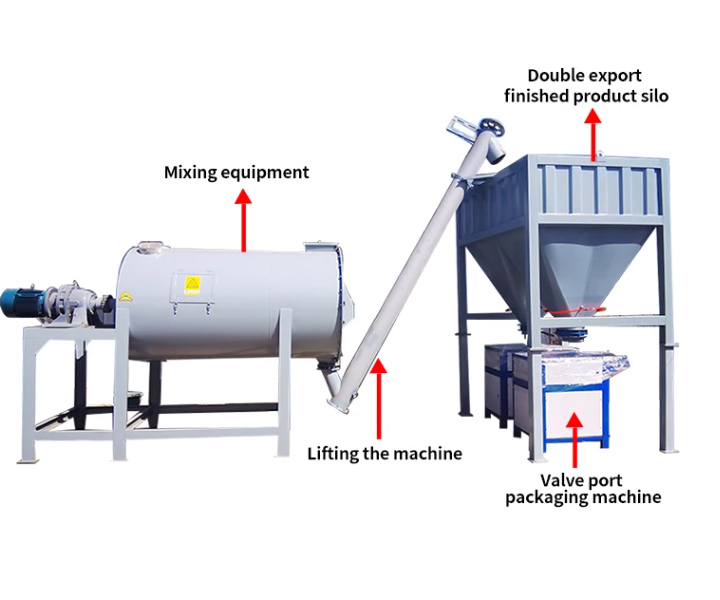

The production line of dry powder mortar mixer usually consists of the following main parts:

1. Raw material handling system: The raw material handling system is used to process and prepare dry powdered materials. It includes raw material storage bins, conveying equipment and weighing equipment.

2. Dry mortar mixer: The dry powder mortar mixer is the core equipment of the production line and is used to mix dry powder materials. According to the specific production needs and requirements, you can choose a suitable mixer type, such as single-shaft spiral type, double-shaft spiral type, etc.

3. Conveying system: The conveying system is used to transport the mixed mortar from the mixer to the next process or storage container. Common conveying equipment includes screw conveyors, belt conveyors, pneumatic conveying systems, etc.

4. Storage and packaging system: The storage and packaging system is used to store and package the mixed mortar. According to production scale and demand.

5. Control system: The control system is used to monitor and control the entire production line. The control system can realize automatic control and regulation of raw material supply, mixing process, transportation and packaging.

Good mixing effect

The use of professional mixers and mixing mechanisms can effectively mix dry mortar materials and additives evenly.

Strong adaptability

It can adapt to different types and formulas of dry mortar materials, as well as the mixing needs of various additives.

Easy to operate

Using automated control system, the operation is simple and convenient. Just set the mixing parameters and start the device for automatic mixing.

Short mixing time

Using an efficient mixer and mixing structure, the mixing process can be completed in a short time.

High mixing uniformity

The mixer is reasonably designed and can fully mix materials, so that the mixed mortar has high uniformity and consistency.

Energy saving

The use of efficient power transmission system and energy-saving design can effectively save energy consumption and reduce production costs.

| Model | LHY-0.25 | LHY-0.5 | LHY-1 | LHY-1.5 | LHY-2 | LHY-3 | LHY-4 | LHY-6 | LHY-8 | LHY-10 |

| One-time mixing (kg) | 100-150 | 200-300 | 400-600 | 600-900 | 800-1000 | 1200-1800 | 1600-2400 | 2400-3600 | 3200-4800 | 4000-6000 |

| Mixing time (min) | 8-20 | 8-20 | 8-20 | 8-20 | 8-20 | 8-20 | 8-20 | 8-20 | 8-20 | 8-20 |

| Mixing speed (r/min) | 60 | 55 | 45 | 40 | 35 | 25 | 25 | 20 | 15 | 15 |

| Motor power (kw) | 3-5.5 | 4-11 | 7.5-15 | 11-18.5 | 15-22 | 18.5-30 | 22-37 | 37-55 | 37-55 | 45-75 |

| Weight (kg) | 500 | 900 | 1800 | 2500 | 3200 | 4100 | 5100 | 6300 | 7500 |

Application materials:

Dry powder mortar mixer is widely used for mixing chemical materials, pharmacy, compound fertilizer, rubber, food, building materials, milk powder, health care products, fodder, additive, breeding industry, bioengineering, fine chemical engineering, cement, gypsum, lime, ceramics, fireproofing, rare earth, plastic, puffing , etc.

Application industries of dry powder mortar mixers are very wide, mainly including the following aspects:

1. Building construction: In building construction, dry powder mortar mixers are widely used in wall masonry, plastering, ceramic tile pasting, putty construction and other processes.

2. Building decoration: In indoor and outdoor decoration, dry powder mortar mixers are often used to prepare wall putty, tile adhesive, waterproof coating and other materials.

3. Engineering repair: In engineering maintenance and repair, dry powder mortar mixer can be used to prepare repair mortar, caulking agent and other materials.

4. Preparation of special materials: Dry powder mortar mixer can also be used to prepare some special materials, such as refractory mortar, thermal insulation mortar, chemical corrosion-resistant mortar, etc.

Xinxiang Dahan Machinery Factory is a company specializing in the production and manufacturing of dry powder mortar mixers. As a well-known manufacturer, Xinxiang Dahan Machinery Factory focuses on product quality and technological innovation. Our dry powder mortar mixer adopts advanced production technology and high-quality materials, with stable performance and reliable operation.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.