Mainly used for dry and wet mixing of feed ingredients to achieve uniform mixing of different ingredients

![]()

![]()

Price:$1,000.00-$7,900.00/Set

Consult now and enjoy a 10% discount

Mixing time: 8-20min

One-time mixing:100-6000 (kg) (If it exceeds 6000kg, it can be customized according to needs)

Mixing speed: 15-60r/min

Frequency: 50HZ、60HZ

Voltage: 380 Volt、Special customized 400v、 480v

Feeding method: manual feeding, automatic feeding or other methods

Discharging method: manual unloading, automatic unloading or other methods

Application: Livestock and poultry breeding, pet food and feed processing industries

Commitment: Free Shipping/5 Days Delivery/30-Day Returns/Support Customization

Feed dry and wet mixer is a piece of equipment specially used for mixing feed raw materials. It can evenly mix dry and wet feed ingredients of different types and proportions to achieve the purpose of improving feed quality and production efficiency.

Feed dry and wet mixers usually consist of a mixing cylinder, a transmission system and a control system. There is a stirrer inside the mixing cylinder, which can fully mix and turn the feed ingredients to ensure that the various raw materials are fully integrated. The transmission system drives the rotation of the mixer through the motor, making the mixing process more uniform and efficient. The control system can adjust mixing time, speed and proportion to meet the requirements of different feed formulas. The use of feed dry and wet mixers can improve the uniformity, digestibility and nutritional value of feed, and improve the growth efficiency and health of animals.

Wet and dry feed mixers are widely used in multiple industries, including:

Feed dry and wet mixers are widely used in the feed processing industry and are mainly used to fully mix dry feed powder and wet feed powder.

Application industries:

Livestock and poultry breeding: Feed dry and wet mixers are widely used in the livestock and poultry breeding industry. It can mix different types and proportions of feed ingredients evenly to ensure that animals receive balanced nutrition. Through the mixer, the digestibility of feed can be improved, nutrient absorption can be increased, and the growth and health of animals can be promoted.

Pet food: Feed dry and wet mixers are also used in pet food manufacturing. It can mix various pet food raw materials (such as meat, grains, vegetables, etc.) to make balanced and nutritious pet food. Through the mixer, you can ensure that pets receive comprehensive nutrition and improve the taste and edibility of food.

Feed processing: Feed dry and wet mixers play an important role in the feed processing industry. It can mix different types of feed raw materials (such as grains, soybean meal, fish meal, etc.) to produce feed products that meet the nutritional needs of different animals. Through the mixer, the uniformity and stability of the feed can be improved, and the production efficiency and product quality can be improved.

Aquaculture: For the aquaculture industry, the feed dry and wet mixer is also one of the important equipment. It can mix fish feed ingredients, including fish meal, shrimp meal, algae, additives, etc., to meet the feeding needs of aquatic animals and promote their healthy growth.

Mixing ingredients:

Dry powder feed: Feed dry and wet mixer is mainly used to mix dry powder feed raw materials, such as grain powder, protein powder, additives, etc. Through the operation of the mixer, these dry powder feed ingredients can be mixed evenly to ensure a balanced distribution of various ingredients in the feed.

Wet powder feed: In addition to dry powder feed, the feeddry and wet mixer is also suitable for mixing wet powder feed ingredients. Wet meal feed usually contains a certain amount of water, such as fish meal, shrimp meal, vegetable meal, etc. The mixer can mix wet powder feed raw materials and dry powder feed raw materials to ensure even distribution of water and improve the edibility of the feed.

The working principle of the feed dry and wet mixer is as follows:

Adding materials: First, add the feed ingredients to be mixed into the mixing cylinder through the feeding port. These raw materials can be dry granular materials, or wet powdery or slurry materials.

Mixing:Once the feed ingredients enter the mixing drum, the mixer starts rotating. The rotating motion of the mixer causes the feed ingredients to continuously flip and cross in the mixing barrel to achieve mixing with each other. This can ensure that different types and proportions of feed ingredients are fully integrated to achieve a uniform mixing effect.

Mixing time and speed adjustment: Mixing time and speed can be adjusted as needed. Different types of feed ingredients may require different mixing times and speeds to achieve optimal mixing results. The control system can adjust the mixer rotation speed and mixing time to meet specific feed formulation requirements.

Discharge: After mixing is completed, the mixed feed will be discharged through the discharge port. The discharge port is usually located at the bottom of the mixing barrel and can be switched on and off through the control system to ensure smooth discharge of feed.

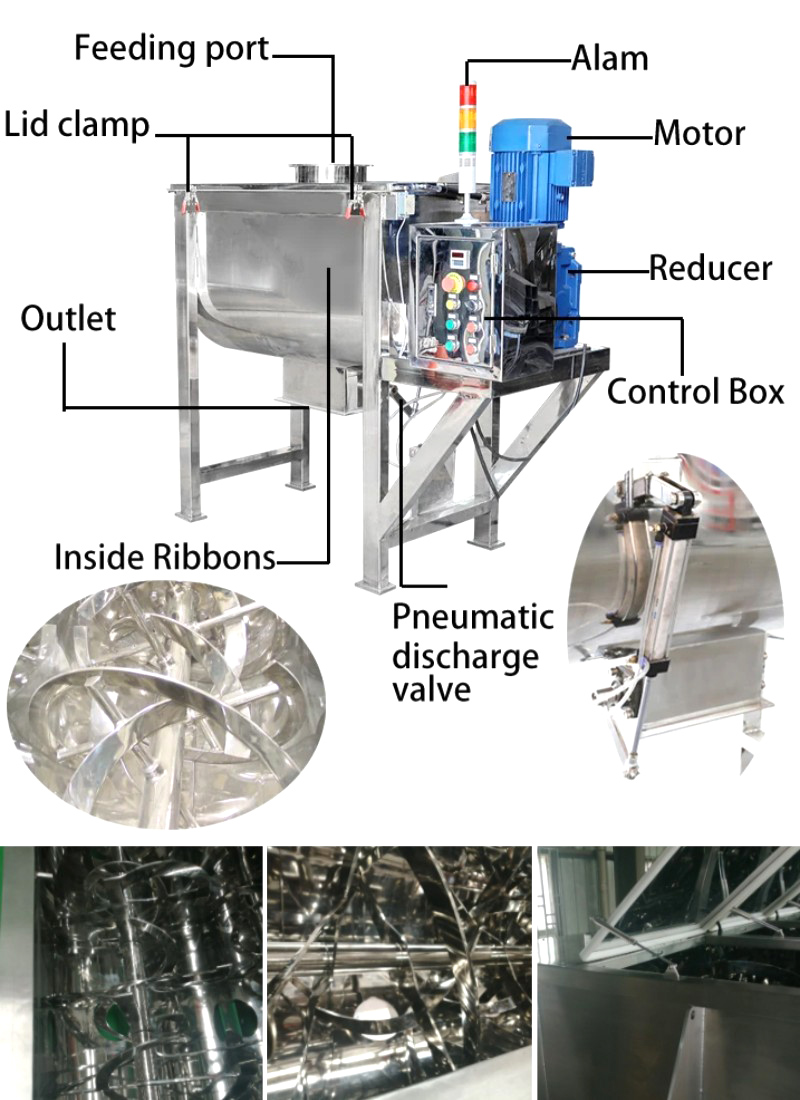

Feed dry and wet mixer has a relatively simple structure but powerful functions. A complete feed dry and wet mixer mainly consists of the following parts:

Mixing barrel: the part used to contain and mix feed raw materials.

Agitator: the part used to mix feed raw materials. Usually, there are agitators of different shapes and structures to choose from, such as spiral agitators, double-shaft agitators, etc.

Motor: provides power to drive the agitator to mix feed raw materials.

Transmission system: transmits the power provided by the motor to the agitator to achieve the mixing of mixed feed raw materials.

Feed inlet and discharge port: the feed inlet is used to put in feed raw materials, and the discharge port is used to take out the mixed feed.

Control system: controls the start and stop, speed and other parameters of the feed dry and wet mixer to ensure safe operation and mixing effect.

Uniform mixing

The feed dry and wet mixer can evenly mix different types and proportions of feed ingredients to ensure that the nutrients in each feed are evenly distributed. This helps improve the animal's digestion and absorption of feed, promoting growth and health.

Improved feed quality

Feed mixed through wet and dry feed mixers has better quality control. The mixing process can ensure the full integration of various raw materials, reduce stratification and separation in the feed, and improve the stability and consistency of the feed.

Cost savings

The feed dry and wet mixer can effectively utilize feed raw materials and reduce waste. Through uniform mixing, unnecessary loss of raw materials can be reduced and the utilization rate of feed can be improved, thereby saving production costs.

Improve production efficiency

The wet and dry feed mixer can mix large quantities of feed ingredients quickly and efficiently. It has efficient stirring and mixing capabilities, can complete the mixing process in a short time, and improves production efficiency.

Flexibility and adaptability

The wet and dry feed mixer can adapt to different types and proportions of feed ingredients. It can handle dry granular materials as well as wet powdery or slurry materials, and has strong adaptability and flexibility.

Automated control

Modern feed dry and wet mixers are usually equipped with advanced automated control systems that can achieve precise control of the mixing process. It is easy to operate, and the mixing time, speed and other parameters can be adjusted as needed to improve the convenience and accuracy of operation.

Based on the different structures and functions, feed dry and wet mixers can be divided into the following types:

Vertical mixer: The mixing barrel is vertical, suitable for small and medium-sized farms, with simple structure and easy operation.

Horizontal mixer: The mixing barrel is horizontal, suitable for large-scale farms, with large mixing capacity and good mixing effect.

Spiral mixer: It uses spiral blades for mixing, with uniform mixing effect, suitable for mixing viscous materials.

Double-shaft mixing feed dry and wet mixer: There are two mixing shafts inside the equipment, which can achieve more complete mixing and stirring, suitable for medium-sized feed manufacturers.

Feed dry and wet mixer can mix both dry feed and wet feed, providing more choices and flexibility for the breeding industry.

| Dry Feed Mixing | Wet Feed Mixing | |

|

|

|

| Raw material features | Dry feed usually includes powdered or granular feed materials, such as corn meal, soybean meal, etc. | Wet feed contains moisture, such as silage, fermented feed, etc. |

| Advantages | Easy to store, transport and use, relatively low cost, good mixing effect. | Moisture helps mixing and shaping, improves the edibility and nutritional utilization of feed. |

| Challenges | Dust is easy to generate, and dust prevention measures need to be taken; some raw materials may absorb moisture, affecting the mixing effect. | It is necessary to pay attention to controlling the moisture content. Too high or too low will affect the mixing effect; it is easy to cause problems such as mold and deterioration. |

| Model | LHY-0.25 | LHY-0.5 | LHY-1 | LHY-1.5 | LHY-2 | LHY-3 | LHY-4 | LHY-6 | LHY-8 | LHY-10 |

| One-time mixing (kg) | 100-150 | 200-300 | 400-600 | 600-900 | 800-1000 | 1200-1800 | 1600-2400 | 2400-3600 | 3200-4800 | 4000-6000 |

| Mixing time (min) | 8-20 | 8-20 | 8-20 | 8-20 | 8-20 | 8-20 | 8-20 | 8-20 | 8-20 | 8-20 |

| Mixing speed (r/min) | 60 | 55 | 45 | 40 | 35 | 25 | 25 | 20 | 15 | 15 |

| Motor power (kw) | 3-5.5 | 4-11 | 7.5-15 | 11-18.5 | 15-22 | 18.5-30 | 22-37 | 37-55 | 37-55 | 45-75 |

| Weight (kg) | 500 | 900 | 1800 | 2500 | 3200 | 4100 | 5100 | 6300 | 7500 |

A pet food manufacturer is a company focusing on pet food manufacturing. In order to improve product quality and production efficiency, they introduced an advanced wet and dry feed mixer. The mixer has efficient mixing capabilities and an automated control system, which can evenly mix pet food ingredients of different types and proportions to ensure product consistency and stability. By using this feed dry and wet mixer, the company successfully improved the quality of pet food, reduced waste of raw materials, greatly improved production efficiency, met the market demand for high-quality pet food, and achieved good economic benefits and Market reputation.

Xinxiang Dahan feed dry and wet mixer manufacturer is a company specializing in manufacturing vibration equipment and one of the feed dry and wet mixer manufacturers. The company has many years of industry experience and advanced production technology, and is committed to providing high-quality, reliable and efficient products. The feed dry and wet mixer adopts high-quality materials and precision processing technology, with stable performance and long life. This product has reasonable design, easy operation and excellent mixing effect. Xinxiang Dahan feed dry and wet mixer has won wide recognition from customers for its excellent manufacturing capabilities and good after-sales service. is one of the trustworthy feed dry and wet mixer manufacturers.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.