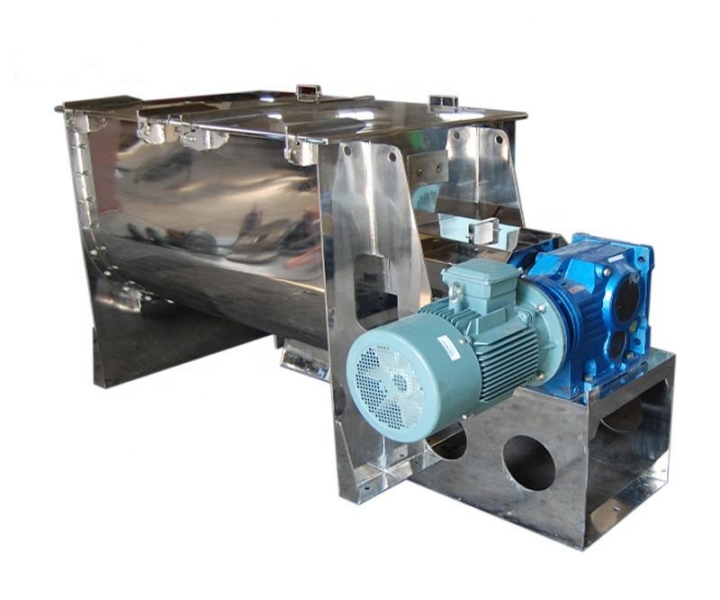

An efficient tool to crush and mix pig feed, and ensure uniform and nutritious feed through mixing and mixing.

![]()

![]()

Price::$1000.00-$7,900.00/Set

Consult now and enjoy a 10% discount

Mixing time: 8-20min

Each mixing amount: 100-6000kg

Capacity: 3000L-11000L

Mixing speed: 115-60r/min

Power: 13.5-75kw

Feeding method: manual feeding, automatic feeding or other methods

Discharging method: manual unloading, automatic unloading or other methods

Application: Animal husbandry, breeding industry, feed processing industry, poultry breeding industry, fishery, pet food industry, animal laboratory, biomass energy industry, agricultural waste treatment and feed additive industry

Commitment: Free Shipping/5 Days Delivery/30-Day Returns/Support Customization

Pig feed crushing mixer is a piece of equipment specially used for livestock and poultry feed processing. It has two main functions: crushing and blending. Through the crushing function, pig feed raw materials such as grains, soybean meal, fish meal, etc. can be effectively ground into particle sizes suitable for pigs to eat. This helps improve feed digestibility and absorption, allowing pigs to better utilize the nutrients in the feed. The stirring function can fully mix feeds with different ingredients to ensure the even distribution of various nutrients in the feed, so that pigs can obtain a balanced nutritional intake and promote their growth, development and health.

The use of pig feed crushing mixer can improve the efficiency of feed processing and ensure the uniformity and nutritional value of feed. It can crush raw materials into particle sizes suitable for pigs to eat, improving the digestibility and absorption rate of feed. At the same time, the stirring function can fully mix feeds with different ingredients to ensure the even distribution of various nutrients in the feed, thereby meeting the pigs' needs for a variety of nutrients. By using a pig feed crushing mixer, the consistency of the feed can be improved, allowing pigs to obtain a balanced nutritional intake, promoting their growth, development and health. This is of great significance to the breeding efficiency and feeding management of pigs.

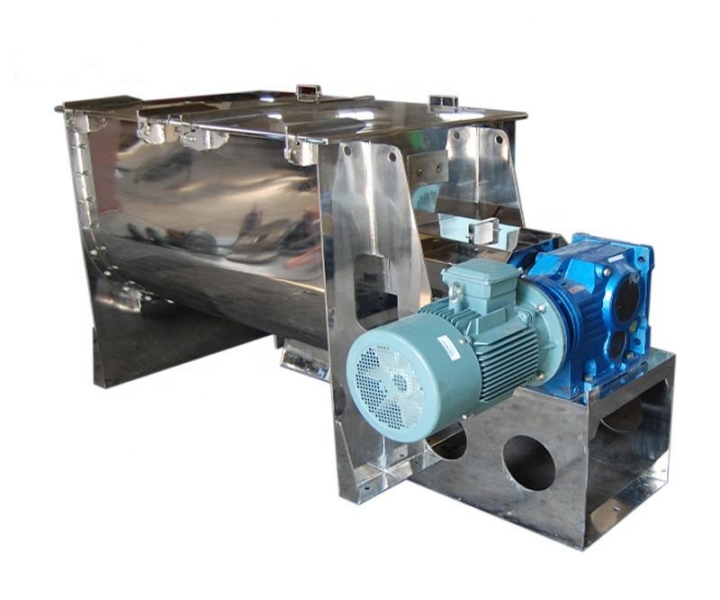

The two common types of pig feed crushing mixers are vertical and horizontal.

Vertical mixer: The way a stand mixer works is that it is arranged vertically. It usually consists of a vertical spindle and an upper pulverizer. The raw materials enter the machine through the upper feed port, and are then crushed into the required particle size by the high-speed rotating blade or hammer of the pulverizer. The crushed feed will automatically drop into the lower mixer for mixing to ensure the uniformity and consistency of the feed. Stand mixers generally have a smaller footprint and are suitable for use in locations with limited space.

Horizontal mixer: Horizontal mixers work in a horizontal arrangement. It usually consists of a horizontal main shaft and a pulverizer and agitator located on the shaft. The raw materials enter the machine through the feed port on the side or front, and are then crushed into the required particle size by the crusher on the horizontal spindle. The pulverized feed will be thoroughly mixed under the action of a mixer. Horizontal mixers usually have larger capacity and higher production efficiency, and are suitable for use in large-scale feedlots or feed processing plants.

Pig feed crushing mixer has a wide range of applications in pig breeding and feed processing industries. Here are some of the main uses:

Crush feed raw materials: The pig feed crushing mixer can crush various feed raw materials such as grains, soybean meal, fish meal, etc. into particle sizes suitable for pigs to eat. This helps improve feed digestibility and absorption, allowing pigs to better utilize the nutrients in the feed.

Mixing feed ingredients: The pig feed crushing mixer can fully mix feed ingredients of different ingredients to ensure the even distribution of various nutrients in the feed. This helps improve feed consistency so the pigs receive a balanced nutritional intake, promoting growth, development and health.

Improve the nutritional richness of the feed:Through the crushing and mixing functions, the pig feed crushing mixer can fully mix different types of feed ingredients, thereby improving the nutritional richness of the feed. This helps meet the pig's multi-nutrient needs and promotes growth and development.

Improve production efficiency: The pig feed crushing mixer can efficiently crush and mix feed, improving the efficiency of feed processing. It can quickly crush and mix large amounts of feed ingredients, reducing production time and labor costs.

Pig feed crushing mixer is usually used to crush and mix feed ingredients to provide balanced feed for pigs. Here is the general working principle of pig feed crushing mixer:

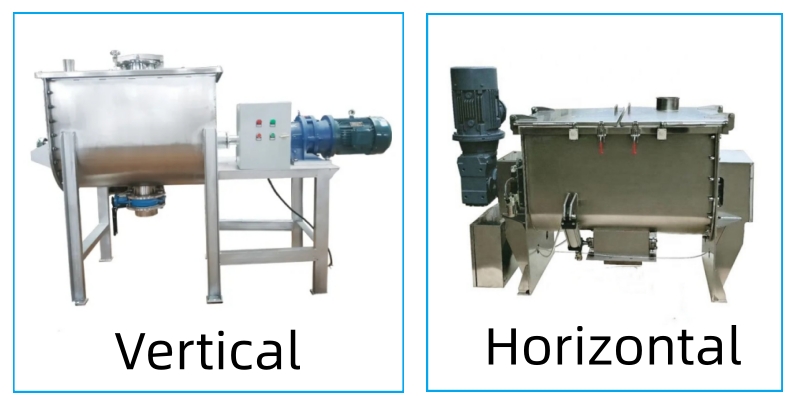

Crushing stage:First, the feed raw materials are put into the crushing tank or crusher. Mixers usually use devices such as hammers, blades or rollers to crush raw materials. When raw materials enter the mixer, these devices apply pressure and shear forces to break the raw materials into smaller particles or powders.

Stirring stage: Once the raw materials are crushed, they will enter the stirring stage. A mixer is usually equipped with a rotating agitator or mixer for mixing the pulverized feed ingredients. The mixer will continuously push and turn the ingredients to mix them evenly, ensuring that each particle contains various nutrients.

Discharge stage:After the mixing is completed, the feed will be discharged from the discharge port of the mixer. The outlet is usually located at the bottom or side of the mixer and is equipped with a door or switch to control the flow of feed. Some mixers can also control the particle size and flow rate of the feed by adjusting the position of the outlet.

Efficiency

The pig feed crushing mixer can efficiently complete the crushing and mixing process and improve production efficiency. It can quickly crush feed ingredients into the required particle size and fully mix feed with different ingredients, saving time and labor costs.

Uniformity

The mixing process ensures that the various ingredients in the feed are evenly distributed, giving the feed a better consistency. This helps the pigs to absorb balanced nutrition, improves feed utilization and the growth effect of the pigs.

Nutrient richness

Through the crushing and stirring process, the pig feed crushing mixer can fully mix different types of feed ingredients to improve the nutritional richness of the feed. This helps meet the nutritional needs of pigs at different growth stages and promotes their healthy growth.

Adjustable crushing effect

pig feed crushing mixer usually has an adjustable crushing effect, and the particle size of the feed can be adjusted as needed. This makes it suitable for pigs of different ages, sizes and health conditions to meet the feeding needs of different stages.

Easy to operate

Pig feed crushing mixer usually has a simple and easy-to-understand operating interface and is easy to operate. The operator only needs to follow the instructions to complete the crushing and mixing process without complicated technical requirements.

Improve feed safety

Through the crushing process, the pig feed crushing mixer can crush the feed ingredients into appropriate particle sizes, helping to improve the edibility and digestibility of the feed. This helps reduce feed waste and pigs' intake of undigested particles, improving feed safety and economic efficiency.

| Model | LHY-0.25 | LHY-0.5 | LHY-1 | LHY-1.5 | LHY-2 | LHY-3 | LHY-4 | LHY-6 | LHY-8 | LHY-10 |

| One-time mixing (kg) | 100-150 | 200-300 | 400-600 | 600-900 | 800-1000 | 1200-1800 | 1600-2400 | 2400-3600 | 3200-4800 | 4000-6000 |

| Mixing time (min) | 8-20 | 8-20 | 8-20 | 8-20 | 8-20 | 8-20 | 8-20 | 8-20 | 8-20 | 8-20 |

| Mixing speed (r/min) | 60 | 55 | 45 | 40 | 35 | 25 | 25 | 20 | 15 | 15 |

| Motor power (kw) | 3-5.5 | 4-11 | 7.5-15 | 11-18.5 | 15-22 | 18.5-30 | 22-37 | 37-55 | 37-55 | 45-75 |

| Weight (kg) | 500 | 900 | 1800 | 2500 | 3200 | 4100 | 5100 | 6300 | 7500 |

A pig farm is a large-scale modern pig breeding enterprise. In order to improve the quality and production efficiency of pig feed, they introduced an efficient pig feed crushing mixer. The application of this machine in pig farms has achieved remarkable results. First of all, through the crushing process, it can quickly crush various feed ingredients into particle sizes suitable for pigs to eat, improve the edibility and digestibility of the feed, and reduce feed waste. Secondly, the mixing process can fully mix feed ingredients of different ingredients to ensure even distribution of nutrients in the feed and improve feed utilization and growth effects of pigs. In addition, the machine is easy to operate, and the operator can complete the crushing and mixing process with simple operations, saving labor costs and time.

Xinxiang Dahan pig feed crushing mixer manufacturer is a company specializing in manufacturing vibration equipment and one of the pig feed crushing mixer manufacturers. The company has many years of industry experience and advanced production technology, and is committed to providing high-quality, reliable and efficient products. The pig feed crushing mixer adopts high-quality materials and precision processing technology, with stable performance and long life. This product has reasonable design, easy operation and excellent mixing effect. Xinxiang Dahan pig feed crushing mixer has won wide recognition from customers for its excellent manufacturing capabilities and good after-sales service. Is one of the trustworthy pig feed crushing mixer manufacturers.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.