Achieve uniform mixing in a gravity-free environment, improve production efficiency, ensure product quality, simplify operating procedures, and create higher value.

![]()

![]()

Price:$500.00-$6,000.00/Set

Consult now and enjoy a 10% discount

Capacity: 5 - 120 cubic feet

Material: Stainless steel

One-time mixing: 100-6000 (kg)

Application: It is widely applied in mixing powder and powder, granule and granule, granule and powder and a bit liquid. It is used for food, chemical, pesticide, feeding stuff and battery etc.

Commitment: Free Shipping/5 Days Delivery/30-Day Returns/Support Customization

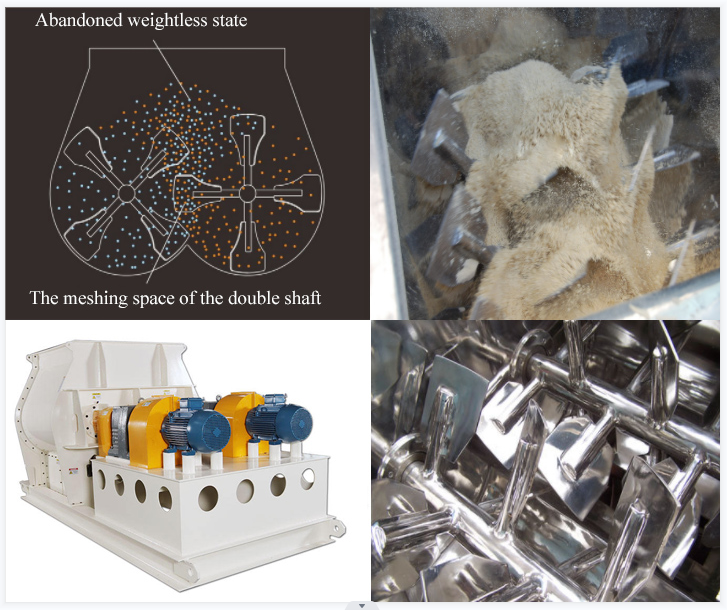

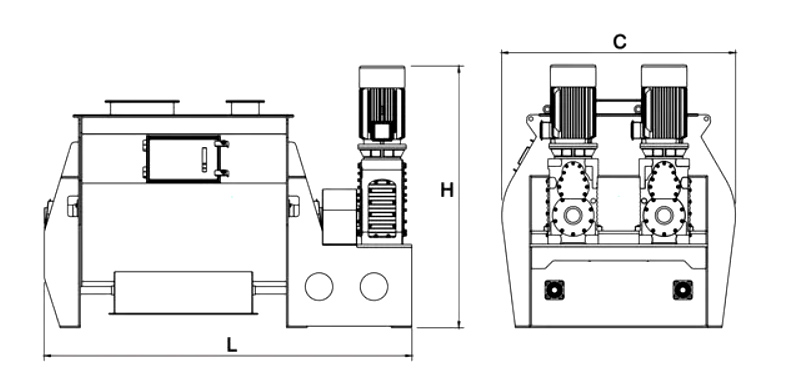

Gravityless twin shaft paddle mixer is an advanced mixing equipment used to uniformly mix powdery, granular and viscous materials. It adopts a dual-shaft paddle design and mixes in a gravityless environment to ensure uniformity and consistency of the mixing effect. The main components of the mixer include mixing cylinder, double-shaft blades, transmission device and control system.

The mixing cylinder is usually made of corrosion-resistant and wear-resistant stainless steel to ensure long-term and stable work. The twin-shaft paddles are installed inside the mixing cylinder, and the transmission device drives the rotation of the paddles to achieve mixing of materials. The control system can adjust the mixer's speed and mixing time as needed to obtain the ideal mixing effect. During the mixing process, creating a gravity-free environment is critical to the mixing effect. This is usually achieved by using inertial centrifugal force or a vacuum environment to keep the material suspended. This can effectively avoid settling and stratification of materials and ensure uniform mixing.

The blade design of gravityless twin shaft paddle mixer can be adjusted according to the characteristics and requirements of the mixed materials to achieve better mixing effects. Here are a few common paddle types:

Propeller Blade

A propeller blade is a common type of propeller blade that has a flat, spiral shape. It can generate powerful stirring and shearing forces and is suitable for mixing viscous materials.

Ribbon blade

A ribbon blade is a broad, flat blade with a spiral shape. It can provide a larger mixing area and stronger stirring effect, and is suitable for mixing powder and granular materials.

Anchor Blade

An anchor blade is a blade with multiple anchor-like arms shaped like an anchor. It can produce large shear force and stirring effect during the mixing process, and is suitable for mixing high viscosity and viscous materials.

Gravityless twin shaft paddle mixers are used in a wide range of industries and applications. The following is a detailed introduction to some common application scenarios and mixed materials:

Chemical industry: In the chemical industry, gravityless twin shaft paddle mixers are often used to mix powders, granules and viscous materials, such as fertilizers, plastic granules, rubber formulations, coatings, dyes and pigments, etc. It enables uniform mixing of different ingredients, ensuring product quality and consistency of chemical reactions.

Food processing industry: In the food processing industry, this mixer can be used to mix powdery and granular food raw materials, such as flour, protein powder, dairy powder, seasonings, feed, etc. It can ensure the even distribution of food ingredients and improve food quality and taste.

Pharmaceutical industry: In the pharmaceutical industry, gravityless twin shaft paddle mixers are widely used in the mixing of pharmaceutical formulas and preparations. It can mix different pharmaceutical ingredients evenly to ensure the effectiveness and stability of the medicine. In addition, it can also be used in the preparation of granules, dry blends and pharmaceutical coatings.

Powder metallurgy industry: In the powder metallurgy industry, this mixer can be used to mix metal powder, ceramic powder and other powder raw materials. It ensures uniform distribution of metal alloys, improving the strength and performance of materials.

Environmental protection industry: In the field of environmental protection, gravityless twin shaft paddle mixer can be used to mix waste and sludge for better handling and treatment of waste. It can mix waste of different components evenly to facilitate subsequent processing and recycling.

Efficient mixing

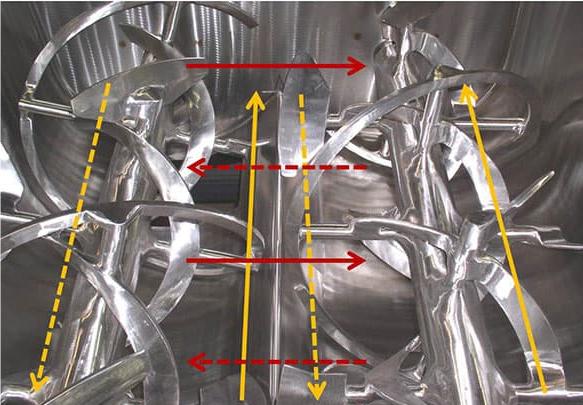

Gravityless twin shaft paddle mixer adopts a twin-shaft paddle design, which causes the material to form a three-dimensional circulation movement in the mixing chamber through rotation and cross action.

Uniform mixing

The materials are circulated and stirred along the axial and radial directions at a certain angle to make the mixing more uniform. The mixing uniformity is as high as 99%.

Multifunctional operation

It can be used to mix different types of materials, and it can also implement different mixing methods, such as shear mixing, folding mixing, and cross mixing.

Durable and reliable

Made of high-quality materials, it has good durability and reliability. They can withstand long periods of high-intensity work, reducing the frequency of equipment maintenance and replacement.

Short mixing time

The mixer only takes 3 minutes to mix powder and 5 minutes to mix liquid mud. An atomizing device can be installed on the cylinder cover to achieve solid-liquid mixing.

Large mixing capacity

Gravityless twin shaft paddle mixer has a large liquid addition range, and the maximum addition amount can reach 20%.

Gravityless twin shaft paddle mixer is equipped with a pair of shafts that rotate in opposite directions in the mixing chamber. Each shaft is installed with a certain angle, a certain number of paddles in an overlapping shape, and a fluid layer is formed in the mixing chamber with a certain peripheral speed. The materials in the layer are mixed under the action of the convective mixing principle, and are in a state of weightlessness in an instant, thus obtaining a uniform mixture.

| Model | Volume(m³) | One-time mixing(kg) | Motor power(kw) | Weight(kg) |

| WZL-1 | 1 | 300-500 | 7.5-11 | 1600 |

| WZL-2 | 2 | 600-1000 | 11-15 | 2300 |

| WZL-3 | 3 | 1000-1500 | 18.5-22 | 2900 |

| WZL-4 | 4 | 1200-2000 | 22-30 | 4800 |

| WZL-5 | 5 | 1800-3000 | 30-37 | 6000 |

The discharge method of gravityless twin shaft paddle mixer can vary according to the specific design and application requirements. The following are some common ways of discharging materials:

1.Bottom discharge: In the bottom discharge mode, the bottom of the mixer is equipped with a discharge port. By opening the discharge door or the movable bottom plate, the mixed material can be discharged from the bottom. This method is suitable for situations where the material needs to be discharged directly from the bottom of the mixer, for example, the mixed material needs to be sent to the next process step or collection container.

2. Side discharge: In the side discharge mode, the side of the mixer is equipped with a discharge port. By opening the side door or movable side plate, the mixed material can be discharged from the side. This method is suitable for situations where the mixed materials need to be discharged sideways, such as when the materials need to be transported to a specific location or equipment.

3. Upper discharge: In the upper discharge mode, the top of the mixer is equipped with a discharge port. The mixed material can be discharged from the top by opening the top cover or movable top plate. This method is suitable for situations where the mixed material needs to be poured from above into a container or equipment below.

4.Discharge materials straight up and down: The top and bottom of the mixer are equipped with corresponding discharge ports, and materials can be discharged by opening the doors or movable plates at the top and bottom. The straight up and straight down discharging method is suitable for situations where the mixed materials need to be poured vertically up or down into the container or equipment below.

1. Choose the batch working capacity from 0.1cbm to 20cbm, select mixer accordingly.

2. Choose raw material for the part contact with raw material, non-contact with raw material, other parts like motor and reducer,bearing material can not be chosen;

According to the material to be mixed, processing condition, health level, raw material can be chosen from mild steel, sus304, sus316L, sus321; And choose the surface treatment according to the raw material.3. Motor power is chosen according to the material gravity, fluidity, and operation.

4. Adding the auxiliary components like spraying, heating and cooling according to processing condition.

5. Mixer inlets: feeding ports, cleaning port, vent.

6. Chose discharging and driven mode: manual, pneumatic and electric.

Gravityless twin shaft paddle mixer is configured on the production process line, combining raw material warehouses, batching systems, conveying systems, finished product warehouses, and packaging equipment in various combinations to achieve large-scale industrial production.

Configuration 1: Use a vacuum feeder to transport materials, a gravityless twin shaft paddle mixer with a finished product bin, and then a packaging machine.

Configuration 2: Manual direct feeding, combined with forklift transportation, the gravityless twin shaft paddle mixer is connected to the ton belt packaging machine.

Configuration 3: Manual feeding into the gravityless twin shaft paddle mixer, secondary lifting and then into the finished product warehouse, and then packaging.

A food processing company encountered the problem of uneven mixing of raw materials during the production process, resulting in unstable product quality. They purchased a gravityless twin shaft paddle mixer to solve the problem. By adjusting the mixer's rotation speed, angle and time, they succeeded in achieving uniform mixing of the ingredients. The quality of the mixed products has been steadily improved, customer satisfaction with the product has been significantly improved, and production efficiency has also been significantly improved. Gravityless twin shaft paddle mixer has become an indispensable key equipment in the company's production process.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.