It can effectively mix different types of fertilizer raw materials evenly, including organic fertilizers, inorganic fertilizers, compound fertilizers, etc.

![]()

![]()

Price:: $300.00-$3,500.00/Set

Consult now and enjoy a 10% discount

Capacity: Up to 1000 Liter

Frequency: 50HZ、60HZ

Voltage: 380 Volt、Special customized 400v、 480v (Can be specially customized according to customer requirements)

One-time mixing: 100-6000 (kg) (If it exceeds 6000kg, it can be customized according to needs)

Application: Fertilizer ribbon mixers are widely used in fertilizer production factories, farms, and planting industries to mix chemical fertilizers, organic fertilizers, trace element fertilizers, and additives.

Commitment: Free Shipping/5 Days Delivery/30-Day Returns/Support Customization

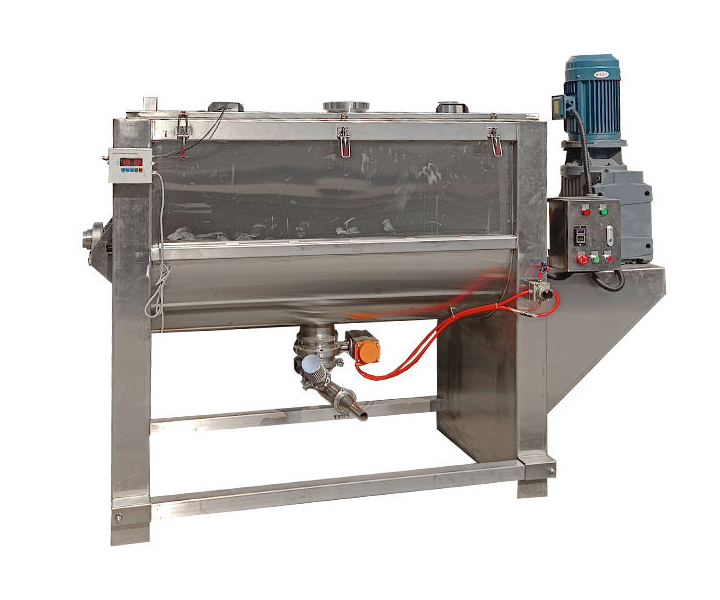

Fertilizer ribbon mixer is a piece of equipment specially used for mixing fertilizer raw materials. Fertilizer ribbon mixer is suitable for mixing and stirring powder or granular fertilizer materials. It can mix fertilizer raw materials of different types and particle sizes, including chemical fertilizers, organic fertilizers, trace element fertilizers and additives, etc.

It has the advantages of fast mixing, uniform mixture, convenient operation and easy cleaning. In addition, fertilizer raw materials are generally corrosive, so fertilizer ribbon mixer is made of 304 stainless steel. The mixer of this material is resistant to acid and alkali and will not react chemically with the raw materials, and can be specially used for mixing various fertilizers, organic fertilizers and chemical raw materials.

Fertilizer ribbon mixer is mainly used to mix different types of fertilizer raw materials to achieve uniform mixing. It has a wide range of applications in the production and use of fertilizers.

Here are some of the main uses for fertilizer ribbon mixers:

1. Fertilizer production plant: In fertilizer production plants, mixers are used to mix different types of fertilizer raw materials to produce uniform compound fertilizer products.

2. Breeding farms: In breeding farms, mixers are used to mix feed raw materials, including various ingredients in feed formulas, such as powders, pellets, additives, etc., to provide a nutritionally balanced feed supply.

3. Planting: In the planting industry, the mixed machine is used for mixed with different types of fertilizer raw materials, including fertilizers, organic fertilizers, trace element fertilizers, etc. to provide comprehensive nutrition required by plants.

Fertilizer ribbon mixers can be used to mix different particles of chemical fertilizers. Common mixed particles include the following:

1. Mixed fertilizer: Particles made by mixing different types of fertilizer particles in a certain proportion, which can provide a variety of nutrients to crops. Common mixed fertilizers include compound fertilizers, compound fertilizers, etc.

2. Slow-controlled release fertilizer: This kind of granules is made of a mixture of different types of fertilizer granules. Through special coating or wrapping technology, nutrients are slowly released over a period of time to meet the needs of crops.

3. Multi-element fertilizer: The mixer can mix different types of fertilizer particles together to form granular fertilizer containing multiple elements, so that crops can obtain a supply of multiple nutrients.

4. Customized fertilizer: The mixer can also mix different types of fertilizer particles in a certain proportion according to the needs of specific crops and soil characteristics to form customized fertilizer particles suitable for specific crops and soil.

Fertilizer ribbon mixer is to put the raw materials into the mixer according to the proportion through the ribbon, start the mixer, the raw materials are stirred and mixed under the push of the spiral blades, the outer ribbon pushes the raw materials to the other side, and the inner ribbon pushes the raw materials to the opposite direction. Pushing, so repeatedly, the raw materials are stirred and mixed evenly under the action of convection. During this process, water, liquid, and spray can be added. Finally, the raw material is discharged through the control valve at the bottom.

| Model | LHY-0.25 | LHY-0.5 | LHY-1 | LHY-1.5 | LHY-2 | LHY-3 | LHY-4 | LHY-6 | LHY-8 | LHY-10 |

| One-time mixing (kg) | 100-150 | 200-300 | 400-600 | 600-900 | 800-1000 | 1200-1800 | 1600-2400 | 2400-3600 | 3200-4800 | 4000-6000 |

| Mixing time (min) | 8-20 | 8-20 | 8-20 | 8-20 | 8-20 | 8-20 | 8-20 | 8-20 | 8-20 | 8-20 |

| Mixing speed (r/min) | 60 | 55 | 45 | 40 | 35 | 25 | 25 | 20 | 15 | 15 |

| Motor power (kw) | 3-5.5 | 4-11 | 7.5-15 | 11-18.5 | 15-22 | 18.5-30 | 22-37 | 37-55 | 37-55 | 45-75 |

| Weight (kg) | 500 | 900 | 1800 | 2500 | 3200 | 4100 | 5100 | 6300 | 7500 |

In fertilizer production enterprises, fertilizer ribbon mixers mix different types and particle sizes of fertilizer raw materials, including chemical fertilizers, organic fertilizers, trace element fertilizers and additives, etc. It can improve the uniformity and nutritional balance of fertilizers.

Fertilizer ribbon mixers are available in a variety of options to meet different fertilizer processing needs and production scales. Here are some common options:

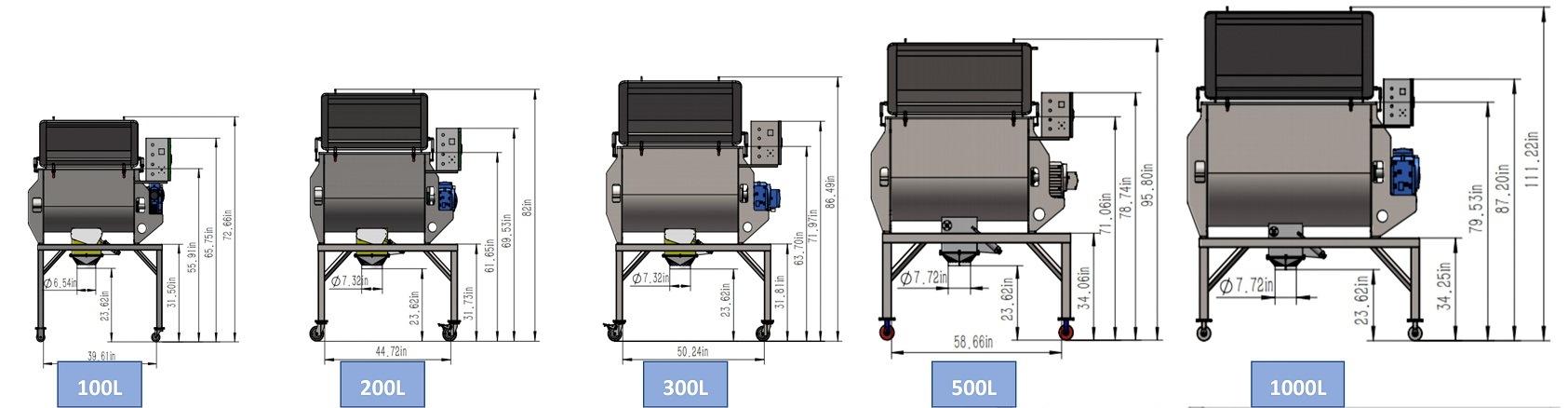

Capacity selection: The capacity of the fertilizer ribbon mixer can be selected according to production needs. There are usually different specifications to choose from, such as 100 liters, 200liters, 300liters, 500 liters, 1000 liters, etc. Larger production scale usually requires larger capacity mixers.

Power selection: The fertilizer ribbon mixer can be powered by electric or diesel power. Choose the appropriate power type according to the actual situation and use environment.

Material selection: The body and mixing part of the mixer are usually made of stainless steel or carbon steel. Stainless steel is corrosion-resistant and suitable for handling feed materials with high humidity.

Control system selection: The fertilizer ribbon mixer can choose manual control or automatic control system. The automatic control system can achieve precise control and parameter adjustment of the mixing process, improving production efficiency and mixing quality.

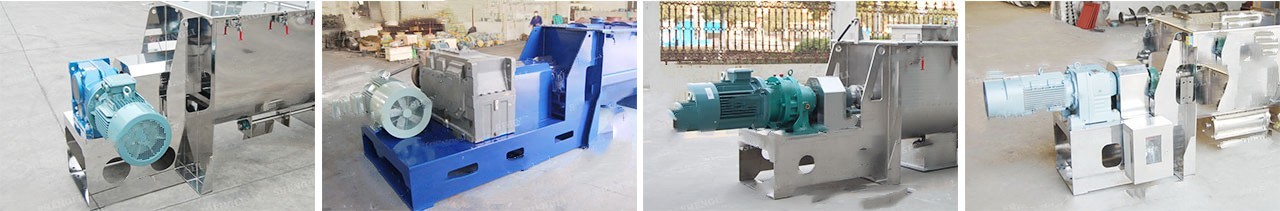

Mixing unit: Different main shaft agitators can be equipped according to the properties of raw materials. The main shaft agitator could be: inner and outer ribbon, paddle and ribbon, disconnected ribbon, and shaver-shaped agitator.

Selection of supporting equipment: According to actual needs, the fertilizer ribbon mixer can choose supporting equipment, such as screw conveyor, unloader, elevator, belt conveyor,etc., to realize an automated feed production line.

Corrosion resistant

The fertilizer raw materials are corrosive, so the mixer is generally made of 304 stainless steel, which is not easy to corrode.

High mixing uniformity

The positive and negative rotating ribbons are installed on a unified horizontal axis to form a low-power mixing environment, which increases the mixing average.

Strong mixing force

On the basis of the original, the motor power, stirring shaft and mixing blade of the ribbon mixer are enlarged to meet the mixing and stirring of fertilizers with high viscosity.

Fast mixing speed

The design of the discharge port adopts the butterfly valve to open the door to discharge the material, so that the viscous fertilizer is easily discharged from the mixer, the discharge is fast.

Simple operation

The operation is relatively simple, just put the raw materials into the mixer, set the mixing time and speed, and start the mixer.

Space-saving

The fertilizer ribbon mixer has a compact structure and a small footprint, saving production space.

Fertilizer ribbon mixers play a key role in fertilizer production. Its main functions include:

Uniform mixing: The fertilizer ribbon mixer can evenly mix different types of fertilizer raw materials to ensure the even distribution of various nutrients in the fertilizer and improve the quality and effect of the fertilizer.

Improve mixing efficiency and production capacity: The ribbon mixer has high mixing efficiency and can quickly complete the mixing process, improve production efficiency and capacity, and save time and labor costs.

Save energy and space: The ribbon mixer has a compact structure, small footprint, and saves production space. The spiral blade movement during the mixing process is relatively energy-saving and reduces energy consumption.

Easy operation: The ribbon mixer is easy to operate. You only need to set the mixing time and speed and start it. No complicated operating skills are required, which improves the convenience and speed of operation.

Wide range of applications: The ribbon mixer is not only suitable for the fertilizer industry, but can also be used for mixing raw materials and finished products in other industries, with a wide range of applications.

Durable and reliable: The ribbon mixer adopts high-quality materials and manufacturing processes, has high durability and reliability, and can adapt to harsh working environments and long-term continuous production.

An agricultural company uses a fertilizer ribbon mixer to handle their fertilizer production. Their fertilizer raw materials include organic fertilizers, inorganic fertilizers and compound fertilizers, each with different compositions and particle sizes. By using a ribbon mixer, they were able to evenly mix different types of fertilizer raw materials, improving the quality and uniformity of the fertilizer. This makes it easier for their fertilizer to be spread evenly during application, improving fertilizer effectiveness. At the same time, the efficient processing capabilities of the mixer also helped them improve production efficiency and reduce production costs.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.