Spiral ribbon dry powder mortar mixer is an important equipment for dry mortar production. It is widely used in the fields of building materials industry, chemical industry and food industry with its high efficiency, uniformity and energy saving, providing efficient and stable mixing solutions for the production process. It rolls and pushes the materials through the rotation of the spiral ribbon to achieve uniform mixing and produce dry mortar products that meet the standards. The following is a detailed introduction to the spiral ribbon dry powder mortar mixer:

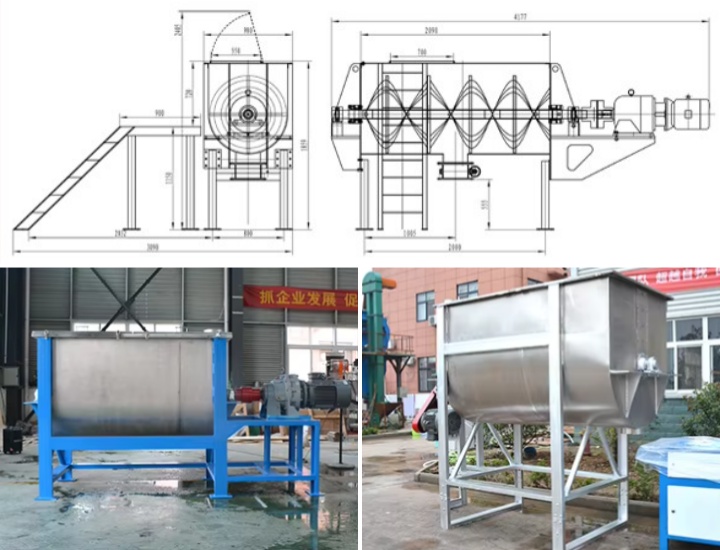

Spiral ribbon dry powder mortar mixer usually includes the following main parts:

Frame: structural frame supporting the entire equipment.

Spiral ribbon: a ribbon designed in a spiral shape for mixing raw materials.

Transmission device: including motor and transmission device, used to drive the rotation of the spiral ribbon.

Feed port and discharge port: used to put in raw materials and take out the mixed products.

Control system: used to control the start and stop, speed and other parameters of the mixer.

Raw material feeding: Dry powdered building materials are added to the spiral ribbon dry powder mortar mixer through the feed port.

Spiral ribbon mixing: Start the transmission device to drive the spiral ribbon to rotate, driving the raw materials to roll and rotate continuously on the spiral ribbon.

Mixing effect: The design of the spiral ribbon allows the raw materials to be fully mixed in the mixer to ensure that the various components are evenly distributed.

Discharging: After mixing, the evenly mixed dry powder mortar is transported to the downstream process through the discharge port.

Excellent mixing effect: The spiral ribbon design allows the raw materials to be fully mixed during the mixing process to ensure the uniformity and quality of the product.

Easy operation: The equipment operation is relatively simple, and the operator can adjust the mixing time and speed as needed.

Space saving: Spiral ribbon dry powder mortar mixer is usually compact and suitable for production and use in limited space.

Wide range of application: In addition to building materials, it can also be used to mix dry powder materials such as chemical raw materials and food additives.

Building materials industry: Spiral ribbon dry powder mortar mixer is mainly used to mix dry powder building materials such as cement, lime, gypsum, etc., and produce concrete, mortar and other products.

Chemical industry: Spiral ribbon dry powder mortar mixer can be used to mix powdered chemical raw materials, such as pigments, pharmaceutical raw materials, etc.

Food industry: Spiral ribbon dry powder mortar mixer can also be used to mix dry powder raw materials such as food additives and seasonings.

Check whether the equipment is intact and whether all parts are in normal condition.

Turn on the power and start the control system.

Convey the raw materials into the mixer through the feeding device respectively.

Set the speed of the spiral ribbon and start the mixing process.

Observe the mixing process to ensure that the materials are mixed evenly.

After mixing, turn off the power and stop the mixing process.

Clean the mixer to ensure that the equipment is clean.

Spiral ribbon dry powder mortar mixer is widely used in building materials and other industries for its excellent mixing effect, simple operation and space saving. Through the scientific and rational use of this equipment, production efficiency can be improved, product quality can be guaranteed, and the production needs of different industries can be met.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.