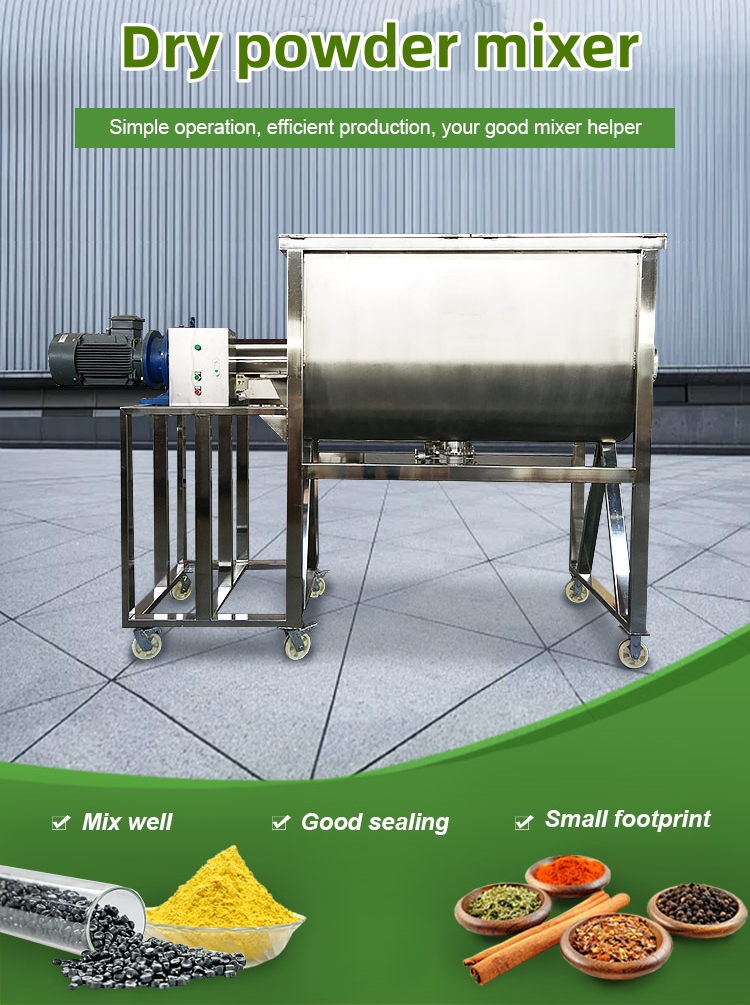

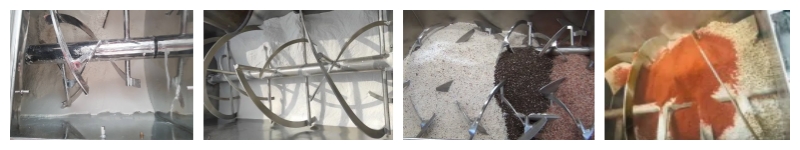

For mixing and uniform distribution of dry powdered or granular materials

![]()

![]()

Price::$1000.00-$7,900.00/Set

Consult now and enjoy a 10% discount

Mixing time: 8-20min

One-time mixing: 100-6000 (kg)

Mixing speed: 15-60r/min

Voltage: 380V

Power: 3-75kw

Feeding method: manual feeding, automatic feeding or other methods

Discharging method: manual unloading, automatic unloading or other methods

Application: Manufacturing Plant, Food & Beverage Factory, Construction works , Food & Beverage Shops

Commitment: Free Shipping/5 Days Delivery/30-Day Returns/Support Customization

Dry powder mixers are essential pieces of equipment in various industries, including pharmaceuticals, food processing, chemicals, and cosmetics. They are designed to efficiently blend and homogenize different dry powders into a uniform mixture.

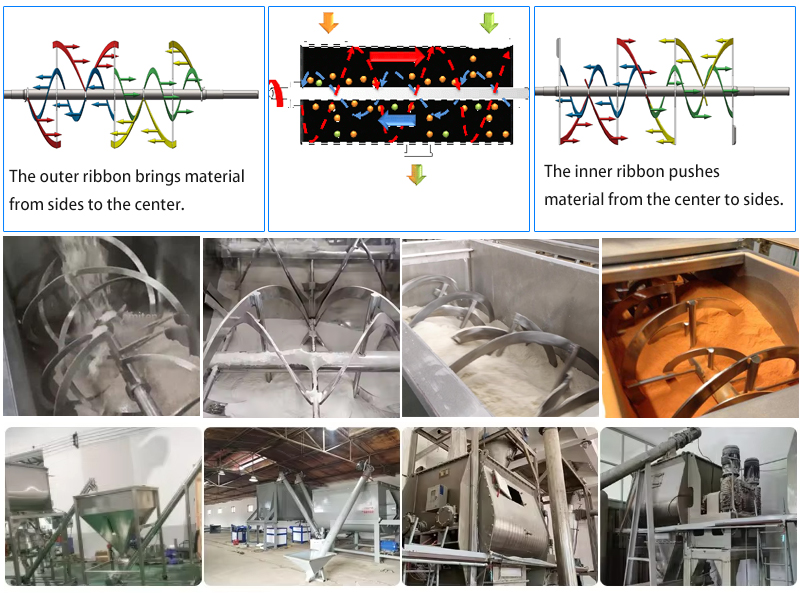

Dry powder mixers are commonly used in the dairy, food and beverage industries and can be either batch or continuous. And, they rely on two different mixing technologies, depending on the physical characteristics of the powder being mixed. For relatively non-cohesive powders (i.e., without particles that tend to stick together), a convection mixing process (such as that found in a ribbon mixer) can be used to thoroughly mix the dry ingredients. However, when the material is cohesive (such as fine powders and wet materials that tend to stick together), a more intensive mixing process using impact or shear forces is required to thoroughly mix the ingredients.

The main functions of dry powder mixers include:

1. Uniform mixing: uniformly mix dry powder or granular materials of different ingredients to ensure the quality consistency of the final product.

2. Improve material fluidity: through mixing, the fluidity of certain materials can be improved, which is convenient for subsequent transportation and packaging.

3. Convenient to add other ingredients: other ingredients such as liquid additives, spices, etc. can be conveniently added during the mixing process.

Dry powder mixers can usually be used to mix various types of powders, including but not limited to:

Fine-grained powder: Some powders with relatively light and delicate specific gravity can be mixed, including flour, powdered sugar, medicinal powder, etc.

Coarse-grained powder: Some powders with relatively large particle sizes include granular seasonings and fertilizers, edible salt, etc.

Mixed powder: Spice powders of different flavors can be mixed together, as well as powder mixtures of various different ingredients such as laundry detergent and chemical powder.

Medicinal powder: In order to achieve a certain use effect, different types of Chinese medicine powders and chemical powders will be mixed together for use.

Food additive powder: Spice powders and edible salt that we eat in life can be mixed with a mixer.

Dry powder mixers include vertical dry powder mixers, horizontal dry powder mixers, V-shaped dry powder mixers and drum dry powder mixers. Here is a brief introduction to the four types:

Horizontal dry powder mixer

It is a mixing equipment designed with a horizontal structure. Its mixing container is usually a rectangular or cylindrical container. The dry powder materials are mixed by the rotation of the main shaft. It is suitable for mixing tasks in small and medium batches, and is easy to operate and clean.

Dry Powder Paddle Mixer

Paddle mixers use paddles or blades that rotate or move through the material to mix it effectively. Due to the strong shearing effect, the mixing time is relatively short, which improves production efficiency and is suitable for mixing pigment powder, gypsum powder, cement powder, putty powder, etc.

V-type dry powder mixer

Its mixing container is V-shaped, with agitators on the upper and lower parts. The V-shaped dry powder mixer mixes dry powder materials through the rotation of the agitator. It is suitable for mixing tasks with high material requirements, and has the advantages of good mixing effect and easy cleaning.

Rotary drum dry powder mixer

Its mixing container is a cylindrical drum with a stirrer installed inside. The dry powder materials are mixed through the rotation of the drum and the movement of the agitator. It is suitable for large-volume mixing tasks and has the characteristics of good mixing effect and short mixing time.

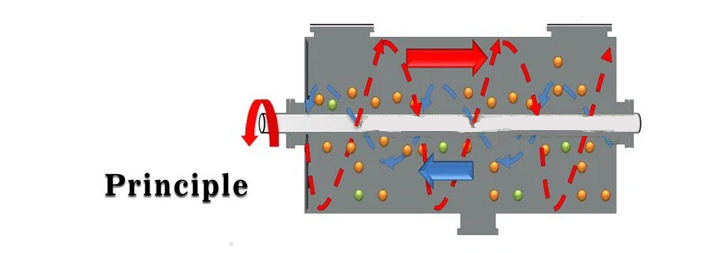

The mixer is equipped with a stirring device, such as a stirring blade, a spiral stirrer, etc. When the mixer is started, the stirring device starts to rotate, pushing the materials from different directions to the center, achieving rapid mixing and uniform distribution of the materials. The movement of the stirring device generates shear force and folding effect, causing the materials to constantly exchange positions inside the container, thereby achieving a mixing effect.

Efficient and fast

The dry powder mixer can quickly mix dry powder materials, greatly improving production efficiency. Its rotational stirring and shearing force make the mixing process faster, saving time and labor costs.

Uniform mixing

Dry powder mixer can achieve uniform mixing of powder materials. Through the action of rotational stirring and shearing force, materials with different components can fully contact and exchange positions, ensuring uniform mixing and improving product quality.

Wide scope of application

Dry powder mixer is suitable for many industries, such as chemical industry, pharmaceutical, food, pesticide, etc. Dry powder materials from different industries can be mixed through dry powder mixers to meet the production needs of different industries.

Easy to operate

The operation of the dry powder mixer is relatively simple, just put the dry powder material into the container and start the mixer. The operation process is not complicated and easy to master and operate.

Energy saving

Dry powder mixers are usually electric-driven, which can save a lot of manpower and energy consumption compared to traditional manual mixing methods.

Improve product quality

Dry powder mixers can achieve uniform mixing of powder materials and ensure full contact and exchange of positions of different ingredients. This helps improve product consistency and quality and reduces batch-to-batch variation.

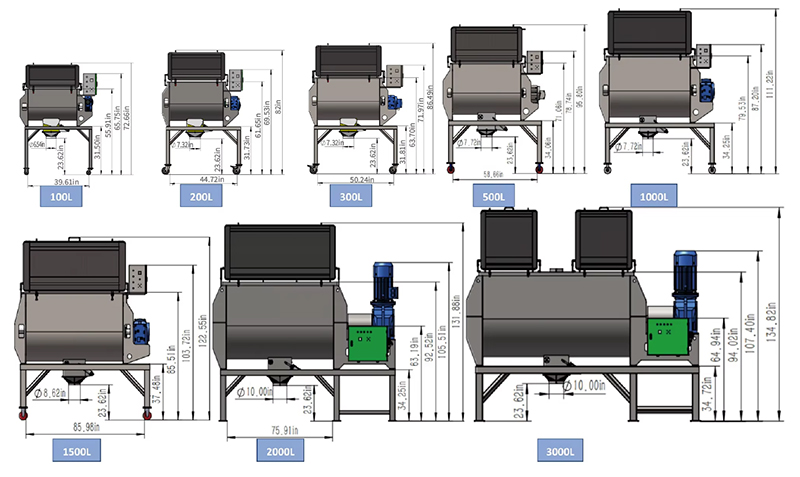

| Model | LHY-0.25 | LHY-0.5 | LHY-1 | LHY-1.5 | LHY-2 | LHY-3 | LHY-4 | LHY-6 | LHY-8 | LHY-10 |

| One-time mixing (kg) | 100-150 | 200-300 | 400-600 | 600-900 | 800-1000 | 1200-1800 | 1600-2400 | 2400-3600 | 3200-4800 | 4000-6000 |

| Mixing time (min) | 8-20 | 8-20 | 8-20 | 8-20 | 8-20 | 8-20 | 8-20 | 8-20 | 8-20 | 8-20 |

| Mixing speed (r/min) | 60 | 55 | 45 | 40 | 35 | 25 | 25 | 20 | 15 | 15 |

| Motor power (kw) | 3-5.5 | 4-11 | 7.5-15 | 11-18.5 | 15-22 | 18.5-30 | 22-37 | 37-55 | 37-55 | 45-75 |

| Weight (kg) | 500 | 900 | 1800 | 2500 | 3200 | 4100 | 5100 | 6300 | 7500 |

The selection of dry powder mixers needs to be considered comprehensively based on factors such as material characteristics, mixing requirements and production scale, among which the humidity of the material is an important influencing factor.

Low humidity dry powder (water content < 5%): good fluidity, easy to disperse, and not easy to agglomerate.

Recommended mixer types:

Double helix cone mixer: high mixing uniformity, suitable for occasions with high requirements for mixing uniformity.

Three-dimensional motion mixer: high mixing efficiency, suitable for occasions with high requirements for mixing efficiency.

V-type mixer: simple structure, easy operation, suitable for small batch and multi-variety mixing.

Medium humidity dry powder (water content 5%-15%): general fluidity, certain viscosity, and slight agglomeration.

Recommended mixer types:

Horizontal ribbon mixer: high mixing uniformity, suitable for occasions with high requirements for mixing uniformity.

Double-shaft paddle mixer: suitable for mixing viscous materials, which can effectively prevent agglomeration.

High humidity dry powder (water content > 15%): poor fluidity, high viscosity, easy to agglomerate.

Recommended mixer types:

Double-shaft paddle mixer: Suitable for mixing high humidity and high viscosity materials, which can effectively prevent agglomeration.

Powerful mixer: High mixing intensity, suitable for occasions with high requirements for mixing uniformity and efficiency.

Additional configuration:

1. Driven unit: Many worldwide famous brands are for option: SEW, ABB, Siemens and so on.

2. Bearings: NSK/SKF and so on

3. Heating/cooling jacket

4. Spraying system

5. Heavy duty type ( loading your material into the mixer first and then start the mixer)

6. Platform: we build the platform for you or we design it and you build it locally

7. Mixing system: including packing machine, bucket elevator, Sieve, screw conveyor and so.

Customizing according to client's specific requirement

Dry powder mixers usually do not work alone. In order to achieve a complete powder material processing process, they are often used in conjunction with vacuum loaders, screw conveyors, vibrating screens and other equipment to form an efficient and complete production line. The following is a detailed introduction to the combination of these equipment and their respective functions:

1. Dry powder mixer with vacuum loaders: extract powder materials from silos or bags and transport them to the mixer through pipes. It can effectively prevent dust from flying.

2. Dry powder mixer with screw conveyors: transport materials from one station to another, such as transporting mixed materials to packaging machines.

3. Dry powder mixer with vibrating screen: sieve the sieved and mixed materials to effectively remove impurities in the materials. The vibrating screen can choose screens with different apertures according to different screening requirements.

A chemical company needs to mix a variety of dry powder materials during the production process to meet product formula requirements. In order to improve mixing efficiency and product quality, they chose an advanced dry powder mixer. This dry powder mixer is efficient and fast, and can quickly and evenly mix powder materials with different ingredients. Through the rotation of the mixer and the action of shear force, the material forms a circular motion in the container, achieving rapid and uniform mixing. This allows the chemical company to increase production efficiency, reduce mixing time, and ensure product consistency and quality. They are very satisfied with the performance and ease of operation of the dry powder mixer, which provides an efficient and reliable mixing solution for their production process, further strengthening their competitiveness in the market.

The following is a dry powder mixer customer case table:

| Client Name | Mixed materials (powders) |

Uses | Mixing time (min) |

Mixing quantity per batch (kg) |

Other instructions |

| Australia ** Pharmaceutical Company | Chinese medicine powders, auxiliary materials | Herbal medicines | 30 | 50 | The mixing uniformity needs to be strictly controlled |

| Bahrain ** Food Company | Milk powder, maltodextrin, vitamins | Infant formula milk powder | 20 | 1000 | A sterile environment is required, and the mixing process needs to be low temperature |

| Vietnam ** Chemical Co., Ltd. | Pigment powder, fillers | Paint production | 45 | 2000 | Material density varies greatly, and it needs to be fully mixed |

| Singapore ** Feed Pte Ltd | Grain powder, soybean meal, additives | Livestock and poultry feed | 15 | 5000 | The mixing uniformity requirement is high, and dust must be prevented from flying |

| Thailand ** Cosmetics Company | Mineral powder, pigments, spices | Foundation liquid raw materials | 10 | 100 | The mixing process needs to be kept at a low temperature to prevent material deterioration |

Xinxiang Dahan is a manufacturer specializing in the production of dry powder mixers with many years of industry experience and technical accumulation. The products produced by the manufacturer include ribbon dry powder mixers, paddle dry powder mixers, drum dry powder mixers, horizontal dry powder mixers, double cone dry powder mixers, V-type dry powder mixers, etc., which are widely used in chemical, pharmaceutical, food and other fields. Xinxiang Dahan pays attention to product quality and technological innovation, and is committed to providing customers with high-quality and high-efficiency dry powder mixing equipment to meet the production needs of different industries.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.