Horizontal dry powder mixer uses a rotating agitator to forcefully mix the materials to achieve a fast and uniform mixing effect.

![]()

![]()

Price:$2,000.00-$10,000.00/Set

Consult now and enjoy a 10% discount

One-time mixing:100-6000kg

Mixing time: 8-20min

Capacity: Up to 1000 Liter

Weight: 100kg-7500kg

Voltage: 380 Volt

Mixed materials: chemical raw materials, feed, food additives, pharmaceutical raw materials, pesticides, dyes, pigments, building materials, metallurgical powders, etc.

Application industries: It is widely used in chemical, pharmaceutical, food processing, feed, agriculture, building materials and other industries.

Commitment: Free Shipping/5 Days Delivery/30-Day Returns/Support Customization

Horizontal dry powder mixer is a device used to mix dry powder materials. It adopts a horizontally placed structure and uses the rotational motion of the mixer to forcefully mix the materials to achieve a fast and uniform mixing effect. The horizontal dry powder mixer has the characteristics of efficient mixing, good stability and multi-functional application. It is widely used in chemical, pharmaceutical, food and other industries to improve production efficiency and product quality.

The horizontal dry powder mixer can mix dry powder materials quickly and evenly through its horizontal design and forced mixing principle. It has stable working performance and large mixing capacity, which can meet the mixing needs of different materials. Horizontal dry powder mixers are widely used in chemical, pharmaceutical, food and other industries. They are suitable for mixing various dry powder materials and can be used in conjunction with other equipment to improve the efficiency and automation of the production line.

The material selection for horizontal dry powder mixers usually includes two common options: carbon steel and stainless steel. Carbon steel is suitable for general industrial scenarios and is economical and practical; while stainless steel is suitable for industries that require high hygiene standards and can maintain the purity of materials. Based on comprehensive considerations such as material characteristics, process requirements, and budget, selecting the appropriate material can ensure the performance and service life of the horizontal dry powder mixer.

Carbon Steel: Carbon steel is a commonly used material that has good strength and durability. Horizontal dry powder mixers made of carbon steel are suitable for general industrial applications and can handle the mixing needs of a variety of dry powder materials. Carbon steel has a lower cost and is an economical and practical choice.

Stainless Steel:Stainless steel is a corrosion-resistant material with excellent durability and hygienic properties. Horizontal dry powder mixers made of stainless steel are suitable for industries that require high hygiene standards, such as food, pharmaceuticals, etc. Stainless steel has anti-corrosion properties, which can prevent the material from reacting with the surface of the equipment and ensure the purity of the mixed material./p>

Horizontal dry powder mixers have important applications in many industries and are used for mixing, stirring and even dispersion of dry powder materials to improve product quality and production efficiency. Specific uses depend on the needs of different industries and material characteristics. Here are some common application areas and uses:

Food processing: Horizontal dry powder mixers can be used in the food processing industry to mix and stir food raw materials, such as flour, powdered sugar, seasonings, dried fruits and nuts, etc., to ensure the uniformity and quality of the product.

Pharmaceutical industry:In the pharmaceutical field, horizontal dry powder mixers are often used for mixing and stirring in the pharmaceutical process. They are used to mix pharmaceutical powders, pharmaceutical raw materials, additives, etc. to ensure uniform distribution and quality stability of the medicine.

Chemical industry: Horizontal dry powder mixers are widely used in the chemical industry for mixing and stirring powdered materials, such as pigments, dyes, catalysts, powder coatings, plastic particles, etc., to obtain a uniform mixture.

Metallurgical industry:Horizontal dry powder mixers can be used in the metallurgical field to mix and stir metal powders, alloy powders, etc. to prepare metal materials or powder metallurgy products.

Environmental protection engineering: In the field of environmental protection, horizontal dry powder mixers can be used to mix and stir environmentally friendly materials, such as sludge, waste disposal, etc.

The horizontal dry powder mixer mixes and stirs dry powder materials through the rotation of the mixing drum and the pushing, throwing and turning functions of the mixing device to achieve uniformity and quality requirements. The working principle is as follows:

Structure: Horizontal dry powder mixer usually consists of a mixing drum and a driving device. The mixing drum is a horizontal cylindrical container with a stirring device inside that can be rotated by a driving device.

Mixing process: First, put the dry powder materials to be mixed into the mixing drum. Then, start the drive device to cause the mixing drum to start rotating. The mixing device usually consists of mixing blades or mixing arms, which continuously push, throw and turn the materials to mix and stir them in the mixing drum.

Time and speed control: The mixing time and stirring speed can be adjusted as needed. Generally, longer mixing time and appropriate stirring speed can achieve a more uniform mixing effect.

Uniformity testing: During the mixing process, the uniformity of the mixture can be verified through sampling testing. If uneven areas are found, the mixing time can be appropriately adjusted or the rotation speed of the mixing drum can be changed to improve the mixing effect.

Discharge: After mixing is completed, the mixture can be taken out of the mixing drum through the discharge port. The unloading method can vary according to the specific design and requirements. Common methods include manual unloading and automatic unloading.

Uniform mixing

The horizontal dry powder mixer can effectively mix and stir the dry powder materials to ensure the uniformity of the materials. The design of the mixing device and the rotation of the mixing drum enable the materials to fully contact and intersect, thereby achieving better mixing effects.

High efficiency and energy saving

Horizontal dry powder mixers are usually driven by power, and the rotation speed and mixing time of the mixing device can be adjusted as needed to achieve efficient mixing effects. In addition, the structural design of the mixing drum also helps reduce energy loss and improve energy utilization efficiency.

Handle a variety of materials

Horizontal dry powder mixers are suitable for processing a variety of different dry powder materials, including food raw materials, chemical materials, building materials, metallurgical powders, etc. It has strong adaptability and can meet the mixing requirements of different industries and products.

Easy to operate

The operation of the horizontal dry powder mixer is relatively simple. You only need to put the dry powder materials into the mixing drum and start the driving device to start the mixing process. Some advanced horizontal dry powder mixers are also equipped with automatic control systems, which can realize automated operation and monitoring.

Easy maintenance

The maintenance of horizontal dry powder mixers is relatively convenient. Usually, the mixing drum and mixing device only need to be cleaned regularly, and lubricated and inspected. The design of the mixing drum and mixing device makes cleaning and maintenance easier.

Save space

The horizontal dry powder mixer has a compact structure and usually occupies a relatively small area, which can save production space. This is very advantageous for factories or workshops with limited space.

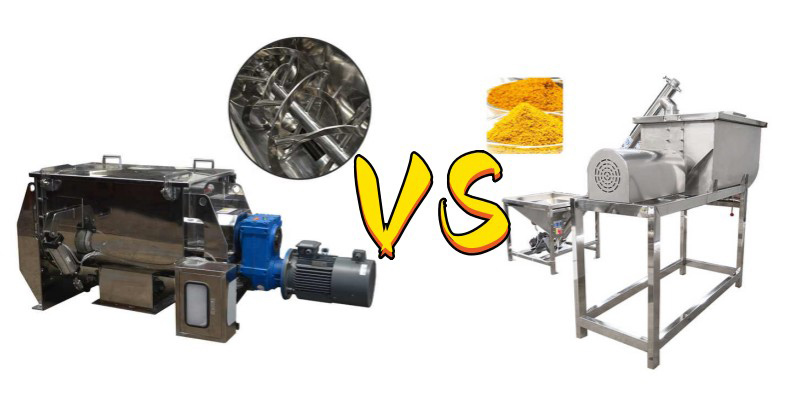

Horizontal dry powder mixer and vertical dry powder mixer are two common mixing equipment. They have some differences in structure and working principle.

Horizontal dry powder mixer:

Structure: The mixing barrel of a horizontal dry powder mixer is usually placed horizontally, and the mixer rotates in the barrel to mix the materials.

Features: The horizontally placed structure allows the material to receive more uniform force and shear during the mixing process, which is conducive to achieving better mixing effects.

Mixing effect: It can evenly mix dry powder materials with different ingredients to ensure that the mixed products have consistent quality and ingredients.

Scope of application: Suitable for mixing a variety of dry powder materials, widely used in chemical, pharmaceutical, food processing, building materials and other industries.

Vertical dry powder mixer:

Structure: The mixing barrel of a vertical dry powder mixer is usually placed vertically, and the mixer rotates the materials from above to downwards.

Features: The vertically placed structure allows the material to move up and down during the mixing process, which is conducive to rapid mixing.

Mixing speed: usually has a high mixing speed, which can quickly mix the materials evenly.

Scope of application: Suitable for some applications that require high mixing time, such as scenes in the pharmaceutical industry that require high mixing of drugs.

| Model | LHY-0.25 | LHY-0.5 | LHY-1 | LHY-1.5 | LHY-2 | LHY-3 | LHY-4 | LHY-6 | LHY-8 | LHY-10 |

| One-time mixing (kg) | 100-150 | 200-300 | 400-600 | 600-900 | 800-1000 | 1200-1800 | 1600-2400 | 2400-3600 | 3200-4800 | 4000-6000 |

| Mixing time (min) | 8-20 | 8-20 | 8-20 | 8-20 | 8-20 | 8-20 | 8-20 | 8-20 | 8-20 | 8-20 |

| Mixing speed (r/min) | 60 | 55 | 45 | 40 | 35 | 25 | 25 | 20 | 15 | 15 |

| Motor power (kw) | 3-5.5 | 4-11 | 7.5-15 | 11-18.5 | 15-22 | 18.5-30 | 22-37 | 37-55 | 37-55 | 45-75 |

| Weight (kg) | 500 | 900 | 1800 | 2500 | 3200 | 4100 | 5100 | 6300 | 7500 |

A building materials company is a company specializing in the production of ceramic tile adhesive. They are faced with the challenge of how to effectively mix and stir dry powder materials to ensure product quality and production efficiency.In order to solve this problem, the company decided to introduce a horizontal dry powder mixer. They chose a well-known equipment manufacturer with extensive experience and technical expertise. After the introduction of a horizontal dry powder mixer, the company's production efficiency has been significantly improved. They can mix dry powder raw materials for ceramic tile adhesive more quickly and evenly, improve product quality stability, and meet customer requirements for consistency. In addition, the mixer's energy-efficient features save the company energy costs and improve the sustainability of production.

Selecting the appropriate mixing blade and mixing speed requires comprehensive consideration of factors such as the particle size, humidity and viscosity of the powder. The following are selection suggestions.

Coarse-grained powder: It is suitable to choose paddle or ribbon stirring blades, which can generate strong axial and radial flow to fully mix the coarse-grained powder.

Fine-grained powder: You can choose turbine or shear stirring blades, which help to disperse and mix fine-grained powder.

Dry powder: Most types of stirring blades are applicable, but you need to pay attention to choosing blades with smooth surfaces to reduce powder adhesion.

Wet powder: It is suitable to choose paddle or ribbon stirring blades, which can generate greater thrust and shear force to overcome the sticky resistance of wet powder.

Low-viscosity powder: You can choose turbine or shear stirring blades, which can generate strong shear force through high-speed rotation to promote powder mixing.

High-viscosity powder: It is suitable to choose paddle or ribbon stirring blades, which can generate greater thrust and shear force to overcome high viscosity resistance.

As a source manufacturer, we have many years of production experience and provide one-stop services including pre-sales, sales and after-sales. The price of our horizontal dry powder mixer varies from $2,000.00 to $10,000.00 per set depending on the model, specification and material. The specific price will be quoted to you based on your production needs. If you need it, you can contact us at any time to get a free quote!

Address:China,Yanjin county forest park gate to the west 1000 meters north road.