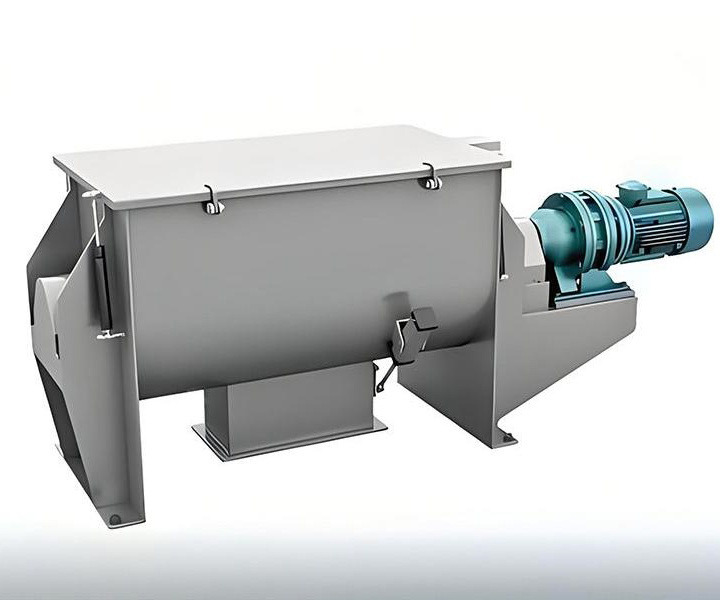

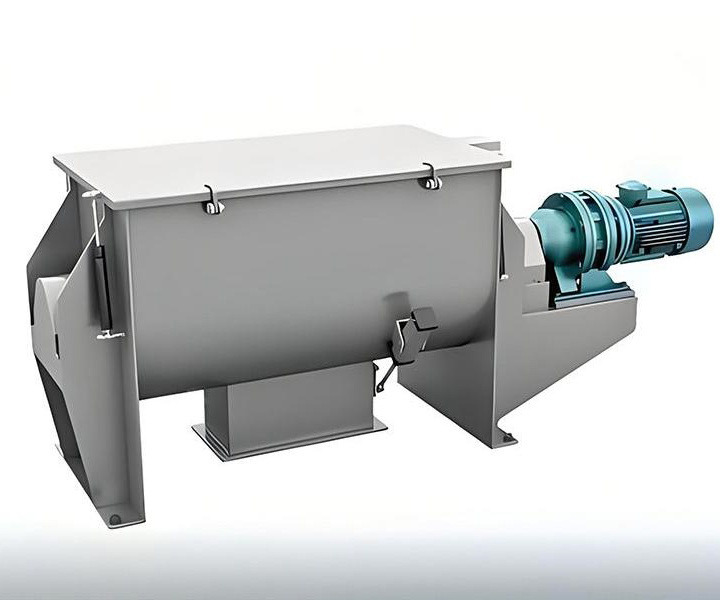

Horizontal concrete mixer is a horizontally placed equipment that mixes cement, aggregate, water, etc. into concrete through a mixing device.

![]()

![]()

Price:$1,099.00-$6,000.00/Set

Consult now and enjoy a 10% discount

One-time mixing:100-6000kg (If it exceeds 6000kg, it can be customized according to needs)

Mixing time: 8-20min

Weight: 100kg-7500kg

Frequency: 50HZ、60HZ

Voltage: 380 Volt、Special customized 400v、 480v (Can be specially customized according to customer requirements)

Application: Horizontal concrete mixers are widely used in construction sites and concrete precast plants to produce various concrete products, such as concrete slabs, concrete pipes, concrete bridges, etc.

Commitment: Free Shipping/5 Days Delivery/30-Day Returns/Support Customization

Horizontal concrete mixers are common equipment used in construction projects for the production of concrete. It usually consists of a frame, mixing system, feeding system, unloading system and control system. In a horizontal concrete mixer, cement, aggregate, water and other additives are input into the mixing system through the feeding system.

The mixing system consists of a horizontal mixing shaft and a mixer. The rotation of the mixer mixes the raw materials evenly to ensure the quality of the concrete. Concrete mixers can efficiently mix various raw materials to produce concrete that meets the requirements. They are widely used in various construction projects, such as house construction, road construction, bridge projects, etc. It is easy to operate and has stable concrete quality. It is one of the indispensable and important equipment in the construction industry.

Horizontal concrete mixers are widely used in construction engineering fields. It plays an important role in various construction projects, including house construction, road construction, bridge projects, water conservancy projects, etc. In these projects, concrete is an essential construction material, and the horizontal concrete mixer is one of the key equipment for producing high-quality concrete.

Horizontal concrete mixers can effectively mix cement, aggregates, water and additives to ensure the uniformity and stability of concrete. It can produce concrete with various strength levels and mix ratios to meet the needs of different engineering projects. Whether it is a small construction project or a large infrastructure project, horizontal concrete mixers provide reliable concrete production solutions.

Horizontal concrete mixers can be divided into different types according to different characteristics and working methods. The following are three common types:

Forced horizontal concrete mixer:

Equipped with a forced mixer, the forced stirring function of the mixer can more thoroughly mix cement, aggregate, water and additives. Suitable for producing high strength and high performance concrete.

Automatic horizontal concrete mixer:

Equipped with an automatic control system, it can realize automated production and improve production efficiency and stability of concrete quality. Suitable for engineering projects that require mass production of concrete.

Mobile horizontal concrete mixer:

It is portable and usually mounted on wheels, making it easy to move and arrange flexibly between construction sites. Suitable for projects that require frequent movement or transfer between different construction sites.

Horizontal concrete mixers achieve mixing through a horizontally placed mixing shaft and agitator. Raw materials include cement, aggregate, water and additives, which are input into the mixing system through the feeding system. The mixer rotates to throw ingredients up and down to mix them. The cement particles are fully mixed with aggregates and water under the action of the mixer to form uniform concrete.

Uniform mixing

The mixer is placed horizontally and can evenly mix cement, aggregate, water and additives to ensure stable concrete quality.

Efficient production

The equipment is easy to operate and has high production efficiency. It can quickly produce large amounts of concrete and improve construction efficiency.

Versatility

Able to produce concrete of various strength levels and mix ratios to meet the needs of different engineering projects.

Cost savings

By precisely controlling the concrete proportions and production process, material waste can be reduced and costs can be saved.

Wide application

Widely used in various construction projects, including house construction, road construction, bridge projects, etc., to provide reliable concrete production solutions for engineering construction.

Reliability

The equipment has a solid structure, stable and reliable operation, ensures concrete quality, and reduces construction risks.

| Model | LHY-0.25 | LHY-0.5 | LHY-1 | LHY-1.5 | LHY-2 | LHY-3 | LHY-4 | LHY-6 | LHY-8 | LHY-10 |

| One-time mixing (kg) | 100-150 | 200-300 | 400-600 | 600-900 | 800-1000 | 1200-1800 | 1600-2400 | 2400-3600 | 3200-4800 | 4000-6000 |

| Mixing time (min) | 8-20 | 8-20 | 8-20 | 8-20 | 8-20 | 8-20 | 8-20 | 8-20 | 8-20 | 8-20 |

| Mixing speed (r/min) | 60 | 55 | 45 | 40 | 35 | 25 | 25 | 20 | 15 | 15 |

| Motor power (kw) | 3-5.5 | 4-11 | 7.5-15 | 11-18.5 | 15-22 | 18.5-30 | 22-37 | 37-55 | 37-55 | 45-75 |

| Weight (kg) | 500 | 900 | 1800 | 2500 | 3200 | 4100 | 5100 | 6300 | 7500 |

A construction company selected a horizontal concrete mixer when working on a large residential development. This equipment provides them with an efficient concrete production solution, ensuring the stability and uniformity of concrete quality. By using horizontal concrete mixers, they are able to produce various proportions of concrete on demand to meet the needs of different stages of the project. This helped them improve construction efficiency, save time and costs, and ultimately successfully complete the project.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.