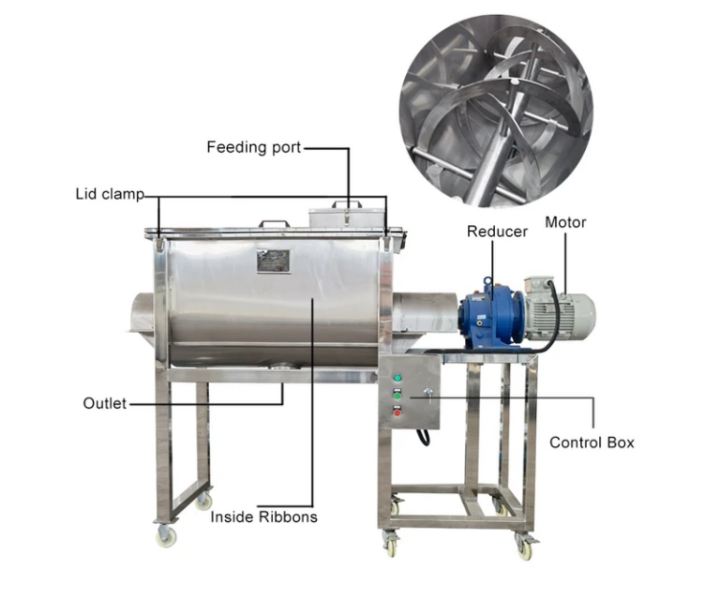

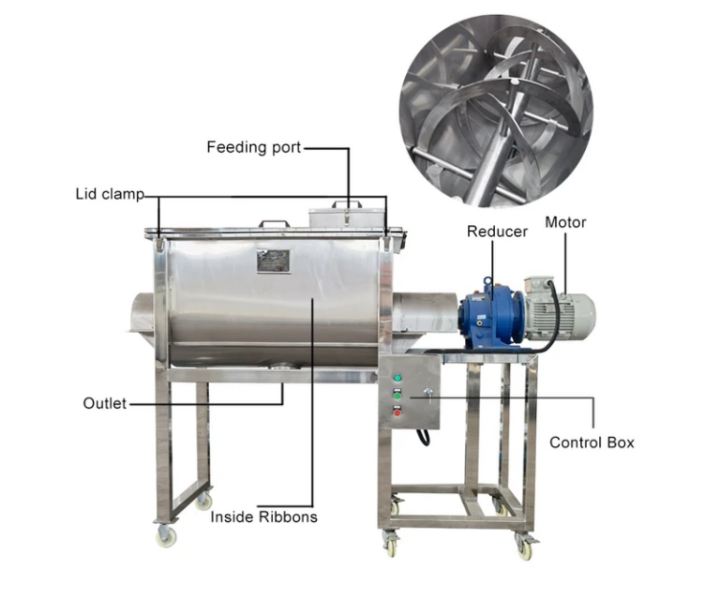

A device made of stainless steel that achieves uniform mixing of different materials through the movement of the ribbon stirrer

![]()

![]()

Price:$1000.00-$7,900.00/Set

Consult now and enjoy a 10% discount

Mixing time: 8-20min

One-time mixing: 100-6000 (kg)

Capacity: Up to 1000 Liter

Mixing speed: 15-60r/min

Power: 3.5-75kw

Application industries: food industry, chemical industry, pharmaceutical industry, agricultural industry, building materials industry, metallurgical industry, electronics industry, environmental protection industry and other fields.

Mixing materials: used to mix various powder and granular materials, including food additives, seasonings, dry powder beverages, food particles, chemical raw materials, pigments, dyes, plastic particles, pharmaceutical raw materials, medicinal powders, tablet granules, pesticides, fertilizers, Feed, cement, gypsum, metal powder, electronic components, waste disposal, etc.

Stainless Steel Ribbon Mixer is a kind of mixing equipment used in industrial production. It is mainly composed of a horizontal ribbon mixer and a container made of stainless steel. Through the rotation and shearing force of the ribbon mixer, it can mix different types of materials together quickly and evenly. Stainless steel ribbon mixers are widely used in chemical, pharmaceutical, food and other industries to mix powder, granular or liquid materials to improve product quality and production efficiency.

The stainless steel ribbon mixer is simple and intuitive to use. The operator only needs to put the materials to be mixed into the container and then start the ribbon mixer. The rotating motion of the ribbon mixer pushes the materials to both sides of the container, creating a shearing and folding effect, thereby achieving uniform mixing of the materials. The choice of stainless steel material makes the mixer have good corrosion resistance and hygiene, and meets the requirements of industrial production.

Stainless steel ribbon mixers have a wide range of applications. Here are some common uses:

Chemical industry: TIn chemical production, stainless steel ribbon mixers are used to mix and evenly disperse various powders, granules or liquid materials, such as dyes, pigments, plastic particles, rubber, resin, etc.

Pharmaceutical industry: In the pharmaceutical process, stainless steel ribbon mixers are used to mix pharmaceutical raw materials, excipients and preparations to ensure the uniformity and consistency of the drugs, such as preparing tablets, capsules and powders.

Food industry:Stainless steel ribbon mixers are widely used in food processing for mixing flour, seasonings, additives, paste materials, sauces, etc. to ensure the uniformity and taste of food products.

Cosmetics industry: In the cosmetics manufacturing process, stainless steel ribbon mixers are used to mix various cosmetic raw materials, such as lotions, creams, shampoos, perfumes, etc., to ensure product quality and stability.

Laboratory research: Stainless steel ribbon mixers are also commonly used in research work in laboratories to mix reagents, samples and experimental materials for reactions, analysis or testing.

The working principle of stainless steel ribbon mixer is as follows:

Structural description:The stainless steel ribbon mixer consists of a horizontal container with a spiral agitator. Spiral agitators usually consist of two or more spiral blades fixed on a central axis.

Stirring motion:: When the stainless steel ribbon mixer starts, the motor drives the central shaft to rotate, causing the spiral agitator to start rotating. The rotating motion of the spiral agitator pushes the material to the sides of the container, creating a shearing and folding effect.

Mixing process: The materials are sheared and folded by the spiral mixer in the stainless steel ribbon mixer, and are constantly cross-mixed. This mixing motion can quickly and evenly mix different types of materials together to achieve even distribution of the mixed materials.

Time control: The mixing time can be adjusted as needed to ensure that the material reaches the required mixing level. Normally, a shorter mixing time will result in a uniform mixing effect.

Uniform mixing

The stainless steel ribbon mixer can mix different types of materials together quickly and evenly through the shearing and folding effects of the spiral mixer to ensure uniform distribution of the mixed materials.

Efficient and fast

Due to the rotation and shearing force of the spiral mixer, the stainless steel ribbon mixer can complete the mixing process in a short time, improving production efficiency.

Strong adaptability

The stainless steel ribbon mixer is suitable for mixing a variety of materials, including powders, granules, liquids and other materials in different forms. It is widely used in chemical, pharmaceutical, food and other industries.

Sturdy and durable structure

The stainless steel ribbon mixer is made of stainless steel, has good corrosion resistance and structural solidity, can adapt to harsh working environments, and has a long service life.

Easy operation

The operation of the stainless steel ribbon mixer is relatively simple. You only need to control the rotation of the mixer by starting the motor, and the mixing time and speed can be adjusted as needed.

Easy to clean

Stainless steel material has a smooth surface and good cleanability, making the stainless steel ribbon mixer easy to clean and maintain, which is helpful to avoid cross-contamination and maintain product quality.

Stainless steel ribbon mixer and paddle mixer are two common industrial mixing equipment. They have some differences in mixing principle, structure and application.

| Comparative Item | Ribbon Mixer | Paddle Mixer |

|

|

|

| Mixing principle | Through the rotation and shearing force of the spiral agitator, the material can be mixed quickly and evenly. | It has a cylindrical or rectangular mixing chamber with a rotating paddle or agitator mounted on the shaft. |

| Structural features | It has a horizontal container and a spiral agitator, which is fixed on the central axis. | usually a vertical or horizontal structure with a container and one or more paddles fixed on a shaft. |

| Mixing effects | It can achieve fast and uniform mixing effect and is suitable for mixing various materials, especially for powder and granular materials. | Due to the driving force of the paddles, it can produce strong shear force and turbulence effect, and is suitable for mixing liquid and viscous materials. |

| Application areas | widely used in chemical, pharmaceutical, food and other industries, suitable for mixing powders, granules and other materials. | commonly used in chemical, pharmaceutical, food, coating and other industries, suitable for mixing, dissolving and homogenizing liquid and viscous materials. |

| Model | LHY-0.25 | LHY-0.5 | LHY-1 | LHY-1.5 | LHY-2 | LHY-3 | LHY-4 | LHY-6 | LHY-8 | LHY-10 |

| One-time mixing (kg) | 100-150 | 200-300 | 400-600 | 600-900 | 800-1000 | 1200-1800 | 1600-2400 | 2400-3600 | 3200-4800 | 4000-6000 |

| Mixing time (min) | 8-20 | 8-20 | 8-20 | 8-20 | 8-20 | 8-20 | 8-20 | 8-20 | 8-20 | 8-20 |

| Mixing speed (r/min) | 60 | 55 | 45 | 40 | 35 | 25 | 25 | 20 | 15 | 15 |

| Motor power (kw) | 3-5.5 | 4-11 | 7.5-15 | 11-18.5 | 15-22 | 18.5-30 | 22-37 | 37-55 | 37-55 | 45-75 |

| Weight (kg) | 500 | 900 | 1800 | 2500 | 3200 | 4100 | 5100 | 6300 | 7500 |

A pharmaceutical company is a satisfied customer of a stainless steel ribbon mixer. The company specializes in the pharmaceutical field, which requires the mixing and homogenization of various powdered raw materials. They chose a stainless steel ribbon mixer as their mixing solution. By using a stainless steel ribbon mixer, the pharmaceutical company achieved an efficient mixing process. The rotation and shearing force of the stainless steel ribbon mixer quickly mixes the powdered raw materials together, ensuring the uniformity and consistency of the mixed materials. In addition, the corrosion resistance and sturdy structure of stainless steel ribbon mixers are also very suitable for the requirements of the pharmaceutical industry. Pharmaceutical companies can safely use stainless steel ribbon mixers to process a variety of chemical raw materials without worrying about equipment damage or product contamination.

Xinxiang Dahan Stainless Steel Ribbon Mixer Manufacturer is a well-known enterprise specializing in the manufacturing of stainless steel ribbon mixers. They are known in the industry for their high-quality products and superior manufacturing processes. As a professional manufacturer, Xinxiang Dahan focuses on product quality and technological innovation. They have an experienced R&D team that is constantly committed to technological improvement and innovation to meet the changing needs of customers. They use advanced manufacturing equipment and precision processing techniques to ensure product accuracy and reliability. Xinxiang Dahan's stainless steel ribbon mixer has the advantages of solid structure and strong corrosion resistance. It is made of high-quality stainless steel materials, can adapt to various harsh working environments, and has a long service life. Their mixers use the rotation and shear force of the spiral mixer to achieve rapid and even mixing of different materials, ensuring the quality and uniformity of the mixed materials.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.