Dry powder mortar mixer is a device used to mix and stir dry powdered mortar materials. It mixes dry powder materials with additives through a rotating mixer and special structural design to obtain a uniform mortar-like material. The following is a detailed introduction to the working principle of dry powder mortar mixer:

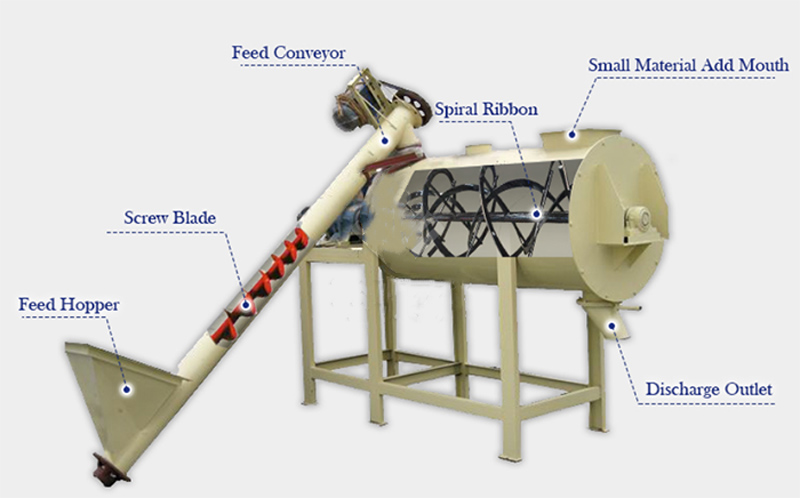

Dry powder mortar mixer usually adopts a vertical structure, with a stirrer at the bottom of the equipment and an inlet and outlet at the top. Agitators usually consist of multiple paddles or spiral blades that can be adjusted and replaced as needed.

Adding materials: First, add dry mortar materials and corresponding additives to the feed port of the mixer in a certain proportion. Additives can be modifiers, thickeners, waterproofing agents, etc., used to improve the performance and stability of the mortar.

Stirring: After starting the mixer, the stirrer starts to rotate, producing strong shear and convection effects. The mixer mixes the dry powder materials and additives together so that they are fully contacted and exchanged to achieve the purpose of mixing.

Mixing time: The mixing time can be adjusted according to specific requirements, generally between a few minutes and tens of minutes. A mixing time that is too long may result in overmixing, affecting the performance of the mortar; a mixing time that is too short may result in uneven mixing, affecting the quality of the mortar.

Discharge: After mixing is completed, the uniform mortar material is discharged through the discharge port. The discharge port is usually equipped with a valve or gate to control the flow and speed of the material.

Dry powder mortar mixer achieves efficient mixing effects through the rotating motion of the mixer and special structural design. The shear and convection effects generated by the mixer enable the dry powder materials and additives to be fully exchanged and mixed, thereby achieving a fast and uniform mixing effect. The mixed mortar material has high uniformity and stability and can meet the requirements of building construction.

The operation of Dry powder mortar mixer is relatively simple and convenient. Just add the dry powder materials and additives into the mixer, start the equipment and start mixing. Equipment is usually equipped with safety protection devices, such as overload protection, limit protection, etc., to ensure the safety of operation. At the same time, the maintenance of the equipment is relatively simple, and routine cleaning and lubrication maintenance can be performed.

To sum up, the dry powder mortar mixer uses a rotating mixer and special structural design to mix dry powder mortar materials and additives to achieve a fast and uniform mixing effect. It plays an important role in construction projects and improves the quality and production efficiency of mortar.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.