The stainless steel animal feed horizontal ribbon mixer is a mixing equipment specially designed for animal feed production. It is made of stainless steel, which is corrosion-resistant and hygienic, and is suitable for food-grade and pharmaceutical-grade feed production. The equipment adopts a horizontal structure and uses the pushing, turning and stirring functions of the spiral blades and spiral belts to evenly mix different types of feed raw materials.

Stainless steel animal feed horizontal ribbon mixer has the advantages of uniform mixing, high efficiency and corrosion resistance, and is widely used in the following animal feed processing scenarios:

Multiple raw material mixing: In large-scale feed production, multiple raw materials such as corn, soybean meal, fish meal, minerals, vitamins, etc. need to be accurately mixed. Horizontal ribbon mixers can efficiently mix a large number of different raw materials in a large volume.

Additive mixing: For some trace additives, such as drugs, enzyme preparations, probiotics, etc., horizontal ribbon mixers can evenly disperse them in a large amount of feed raw materials to ensure that the content of additives in each feed is accurate and consistent.

Customized feed production: Large farms usually prepare feed according to the breed, growth stage and health status of their own breeding animals. Stainless steel mixers are corrosion-resistant and can adapt to the processing of various feed raw materials.

Experimental research: In the field of feed research, various feed formulas need to be developed and experimented. Horizontal ribbon mixers can be used to accurately prepare feed samples for experiments.

New feed research and development: When developing new animal feeds, such as environmentally friendly feeds and functional feeds, researchers need to mix some special raw materials or additives with conventional feed raw materials. Stainless steel animal feed horizontal ribbon mixer can meet the mixing needs of new feed ingredients.

1. Stainless steel material: The stainless steel animal feed horizontal ribbon mixer is made of stainless steel and is corrosion-resistant and hygienic. Stainless steel material can prevent chemical reactions between feed raw materials and equipment, ensuring the purity and safety of the feed.

2. Uniform mixing: This equipment achieves uniform mixing of feed raw materials through the pushing, turning and stirring functions of the spiral blades and spiral belts. The mixed feed has a uniform distribution of ingredients, avoiding stratification between particles and improving the quality and nutritional balance of the feed.

3. Stable structure: The stainless steel animal feed horizontal ribbon mixer adopts a horizontal structure design, which is stable and durable. It can withstand the mixing work of large quantities of feed ingredients, ensuring the stability and reliability of the equipment in long-term operation.

4. Easy to operate: The equipment adopts an automatic control system and is easy to operate. Users only need to set parameters such as mixing time and speed, and the equipment can automatically complete the mixing process, reducing the workload of the operator.

5. High efficiency and energy saving: The stainless steel animal feed horizontal ribbon mixer adopts low-speed operation and continuous pushing of the spiral blades, which can reduce energy consumption and achieve energy saving. At the same time, the equipment has good mixing effect, can complete the mixing process in a short time, and improves production efficiency.

1. Feeding: Feed raw materials enter the feed port of the stainless steel animal feed horizontal ribbon mixer through a feeder or other conveying equipment.

2. Spiral blade pushing: The spiral blade is located inside the mixer and fixed on the spiral shaft. When the screw shaft rotates, the screw blades push the feed materials forward. The pushing effect causes particles to collide and flip over each other, promoting the mixing effect.

3. Ribbon movement: The ribbon is located outside the spiral blades and moves in cooperation with the spiral blades. The movement of the ribbon increases the mixing degree of the particles, making the particles more evenly distributed inside the mixer.

4. Discharge: The mixed feed is discharged from the discharge port of the mixer. The discharge speed can be controlled by adjusting the opening and closing of the discharge port.

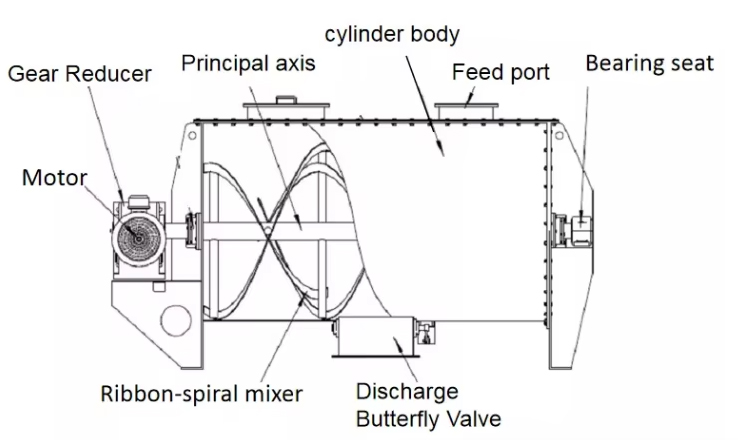

Stainless steel animal feed horizontal ribbon mixer mainly consists of the following parts:

Mixing tank: usually a long U-shaped or cylindrical cylinder structure, generally made of stainless steel. This structural design can ensure the small resistance movement of the mixed material in the cylinder. At the same time, the stainless steel material has good corrosion resistance and wear resistance, and the inner surface is hard and smooth.

Mixing shaft and ribbon blade: The mixing shaft runs through the mixing tank, and spiral ribbon blades are installed on the shaft, which are generally made into double or triple layers. The outer spiral gathers the material from both sides to the center, and the inner spiral transports the material from the center to both sides.

Transmission parts: including motors, reducers and couplings. The motor provides power, and the high-speed rotation of the motor is reduced to a speed suitable for mixing through the reducer. The coupling is used to connect the motor, reducer and mixing shaft to ensure the effective transmission of power.

Feeding port and discharging port: The feeding port is located at the upper part of the mixing tank and is used to put in various feed raw materials. The discharging port is located at the bottom or side of the mixing tank and is used to discharge the mixed feed. The discharge port is usually equipped with a gate or valve to control the speed and flow of the discharge.

| Model |

Power (KW) |

Capacity (L/Volume) |

Max Mixing Powder Weight (kg/batch ) |

Mixing time (mins/batch) |

Size L*W*H (cm) |

| THMR100 | 3 | 280 | 100 | 180*70*150 | |

| THMR300 | 4 | 480 | 300 | 6--8 | 240*80*190 |

| THMR500 | 5.5 | 700 | 500 | 8--10 | 270*90*200 |

| THMR1000 | 7.5 | 1500 | 1000 | 8--10 | 310*110*200 |

| THMR1500 | 11 | 2100 | 1500 | 8--12 | 310*110*200 |

| THMR2000 | 15 | 3200 | 2000 | 8--12 | 350*130*240 |

| THMR3000 | 18.5 | 4300 | 3000 | 10--16 | 375*135*240 |

| THMR5000 | 22 | 6400 | 5000 | 10--16 | 390*165*270 |

The following are some optional equipment related to stainless steel animal feed horizontal ribbon agitator:

Batching scale: It can automatically complete the measurement and addition of raw materials according to the set weight, improve the accuracy and stability of the feed formula, and ensure the balanced nutritional components of animal intake.

Liquid addition system: If liquid ingredients such as oil, vitamin solution, and drug solution need to be added to the feed, the liquid addition system can accurately control the amount of liquid added and spray it evenly on the feed raw materials.

Dust removal equipment: A large amount of dust will be generated during feed processing, which will not only pollute the environment, but may also affect the health of operators and the normal operation of equipment. Dust removal equipment such as pulse bag dust collectors, cyclone dust collectors, etc. can effectively collect dust.

Electronic control system: It can set parameters such as mixing time, speed, feeding and discharging order, and can also perform fault diagnosis and protection on the equipment to improve the stability and reliability of the feed processing process.

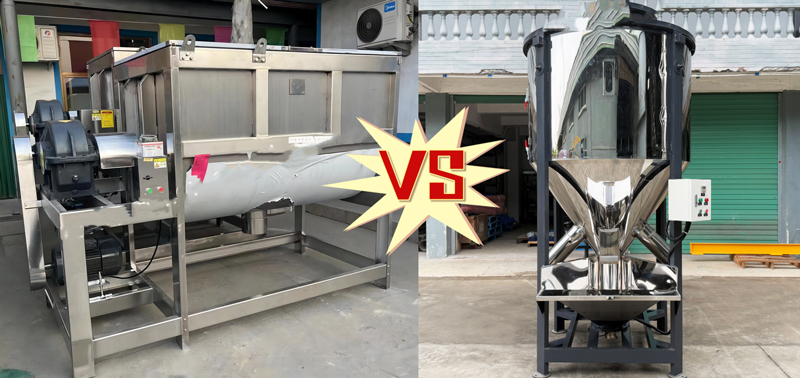

| Comparison Items | Horizontal Ribbon Blender | Vertical Blender |

| Structural Design | Has a horizontally placed mixing shaft with spiral ribbon blades. Generally a horizontal cylindrical structure, and materials are mixed in the cylinder by the ribbon blades. | The material is fed from the lower feed port, lifted by the lifting screw and enters the vertical screw conveyor. After reaching the top, it is thrown out in an umbrella shape, falls around the mixing barrel, and then re-enters the vertical screw conveyor from the notch at the bottom of the sleeve. |

| Working Principle | The rotating spiral blades push the material to flow horizontally, forming convection and shear in the mixing chamber to achieve the purpose of uniform mixing. | Through the rotating shaft and blades to lift the materials to a certain height, and then the materials fall freely and mix with the lower materials. Mainly use the up - down circular motion of the materials to achieve mixing. |

| Application Scenarios | It is suitable for large-scale and efficient feed mixing operations, such as large feed processing plants, where a large number of different raw materials can be quickly mixed in a short time. | More suitable for small - scale and refined feed mixing. Often used in rural farmers, small - scale farms, and small - and medium - sized feed mills. |

| Mixing Efficiency | Strong mixing ability and short mixing time, generally only 3 - 4 minutes per batch. | The mixing time is relatively long, generally 10 - 20 minutes per batch. |

A large animal feed processing plant introduced a stainless steel animal feed horizontal ribbon mixer to mix feed raw materials. After using the equipment, they found that the mixing effect was significantly improved and the uniformity of feed ingredients was greatly improved. At the same time, the application of stainless steel ensures the hygiene and safety of the feed. This enables them to produce high-quality, safe and reliable animal feed products, improving the market competitiveness of their products.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.