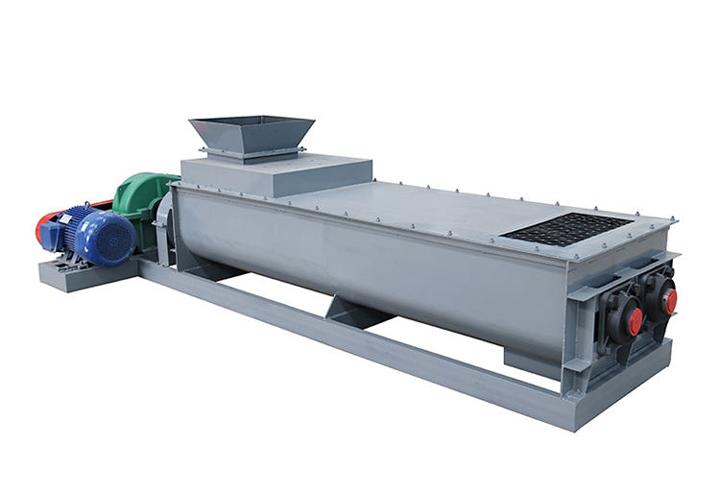

As an important industrial raw material, resin powder is widely used in many fields such as plastics, rubber, coatings, adhesives, etc. Resin powder continuous mixer is an industrial equipment specially used for continuous mixing of powdered materials such as resin powder. Its main function is to evenly mix resin powder with other additives or materials through the stirring device in the mixing chamber to ensure the quality of the mixed materials. Its automatic control system and energy-saving design make it easy to operate, highly stable, and save energy costs. The reliability and durability of resin powder for continuous mixer make it an indispensable and important equipment in industrial production.

Mixing cylinder: The mixing cylinder is the main body of the mixer, usually made of wear-resistant and corrosion-resistant materials, and designed into a cylindrical shape or other shapes suitable for mixing.

Stirring device: The stirring device is the core of the mixer, mainly responsible for tumbling and mixing the materials to make them evenly distributed. Common stirring devices include blade stirrers, propeller stirrers, twin-shaft paddle stirrers, etc. Different stirring devices are suitable for different material properties and mixing requirements.

Feeding system: The feeding system is used to continuously and evenly feed the resin powder into the mixing cylinder. Common ones include screw conveyors, belt conveyors, bucket elevators, etc.

Discharging system: The discharging system is responsible for discharging the mixed resin powder from the mixing cylinder. Common ones include screw conveyors, belt conveyors, pneumatic valves, etc.

Choose the appropriate discharging method according to production needs.

Control system: The control system is responsible for controlling the operating parameters of the mixer, such as stirring speed, feeding speed, discharging speed, etc. Modern resin powder for continuous mixers usually use PLC control systems, which can realize automatic operation.

Efficient mixing: The continuous mixing method can mix materials with higher efficiency. Compared with traditional intermittent mixers, it can complete the mixing task in a shorter time and improve production efficiency.

Precise control: Equipped with advanced control systems, it can accurately control parameters such as mixing time, stirring speed, feeding speed, etc., to ensure the uniformity and consistency of the mixed materials and meet the requirements of different production processes.

Continuous production: Continuous production is achieved without stopping to change materials, ensuring the smoothness and stability of production, and meeting the needs of modern industrial production for high efficiency and high output.

Energy saving and environmental protection: The use of efficient stirring device and advanced control system can effectively reduce energy consumption, reduce pollution emissions, and meet environmental protection requirements.

Safe and reliable: Resin powder for continuous mixer is made of high-quality materials and advanced technology, with a stable structure and reliable operation.

Resin powder continuous mixer is widely used in the following fields:

Plastic industry: used to mix various resin powders and produce various plastic products, such as plastic sheets, pipes, profiles, films, etc.

Rubber industry: used to mix rubber powder and produce various rubber products, such as tires, rubber products, etc.

Coating industry: used to mix resin powder, pigments, fillers, etc. to produce various coating products.

Adhesive industry: used to mix resin powder, fillers, additives, etc. to produce various adhesive products.

Production scale: Select the appropriate mixer size and capacity to meet production needs.

Material properties: Consider factors such as particle size, density, moisture content, etc. of the material, and select the appropriate stirring device and mixing time.

Mixing accuracy: According to the quality requirements of the product, select the appropriate mixing accuracy to ensure the stability and consistency of product quality.

Operation and maintenance: Choose a mixer that is easy to operate and maintain to reduce labor and maintenance costs.

The application of resin powder for continuous mixer has brought convenience and benefits to industrial production, improved production efficiency, and ensured product quality. Its efficient mixing, energy saving, reliable and stable characteristics make it an indispensable and important equipment in the chemical, pharmaceutical and other industries, contributing to the development of industrial production. With the continuous advancement of industrial technology, resin powder for continuous mixer will continue to play an important role in promoting industrial production towards a more efficient and environmentally friendly direction.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.