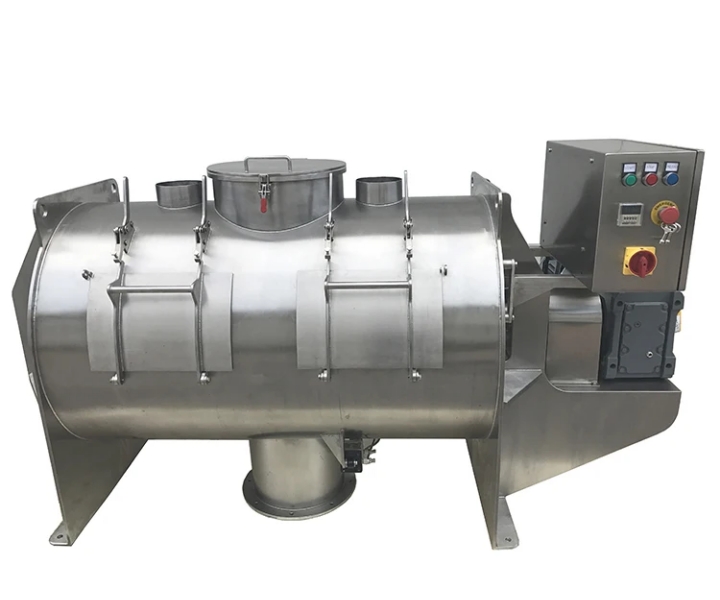

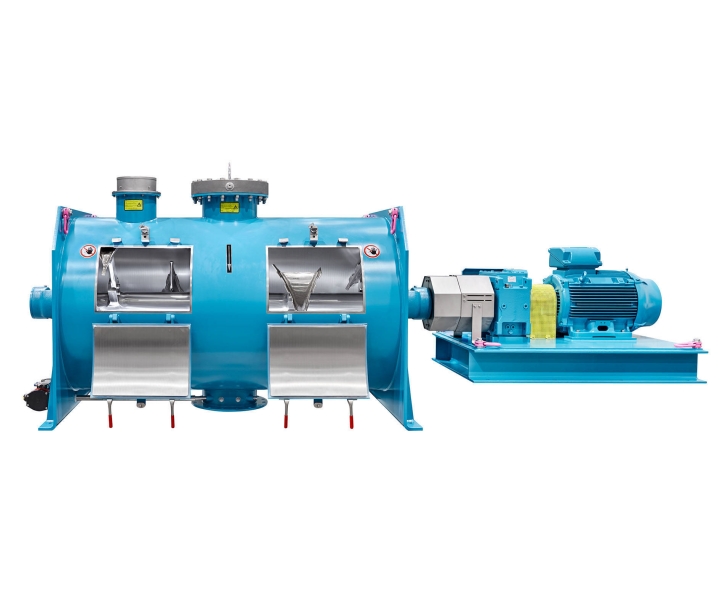

Used to continuously mix and evenly disperse different materials, and continuously add, mix and discharge materials

![]()

![]()

Price:$2,000.00-$10,000.00/Set

Consult now and enjoy a 10% discount

One-time mixing: 100-6000kg

Mixing time: 8-20min

Mixing speed: 15-60r/min

Weight: 500 kg-7500kg

Material: Carbon Steel, Stainless Steel

Application: It is used in the fields of chemical industry, pharmaceutical, food, feed, environmental protection and mining for continuous mixing of chemicals, pharmaceutical raw materials, food additives, feed raw materials, wastewater treatment chemicals, ores and other materials.

Commitment: Free Shipping/5 Days Delivery/30-Day Returns/Support Customization

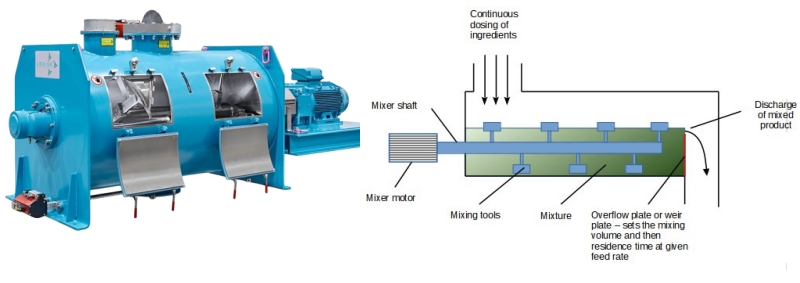

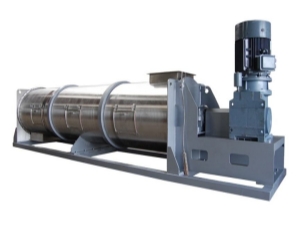

Continuous mixers are industrial equipment designed to continuously blend various ingredients in a controlled manner. Unlike batch mixers that process a specific quantity of materials at a time, continuous mixers provide a steady stream of mixed product, making them ideal for large-scale production processes.Continuous mixers are often used in the production of materials such as concrete, food products, pharmaceuticals, and chemicals.

The Continuous mixer can be easily integrated into downstream continuous processes, such as extrusion or filling, packaging or film production lines, with capacities ranging from pharmaceutical applications (oral solid dosage: 1 - 1,000 kg/h) to chemical and food applications (a few hundred kilograms/hour up to 20,000 kg/h) up to high volume plastics mixing (100 tons/hour), which is upstream of extrusion. Mixing (100 tons/hour). Larger operations will benefit from continuous mixing because of shorter mixing times and higher throughput. Thanks to automated controls, less manual labor is required, which saves manpower and allows for better time allocation.

A continuous mixer is a device used to continuously mix materials, usually in industrial production. Its functions include:

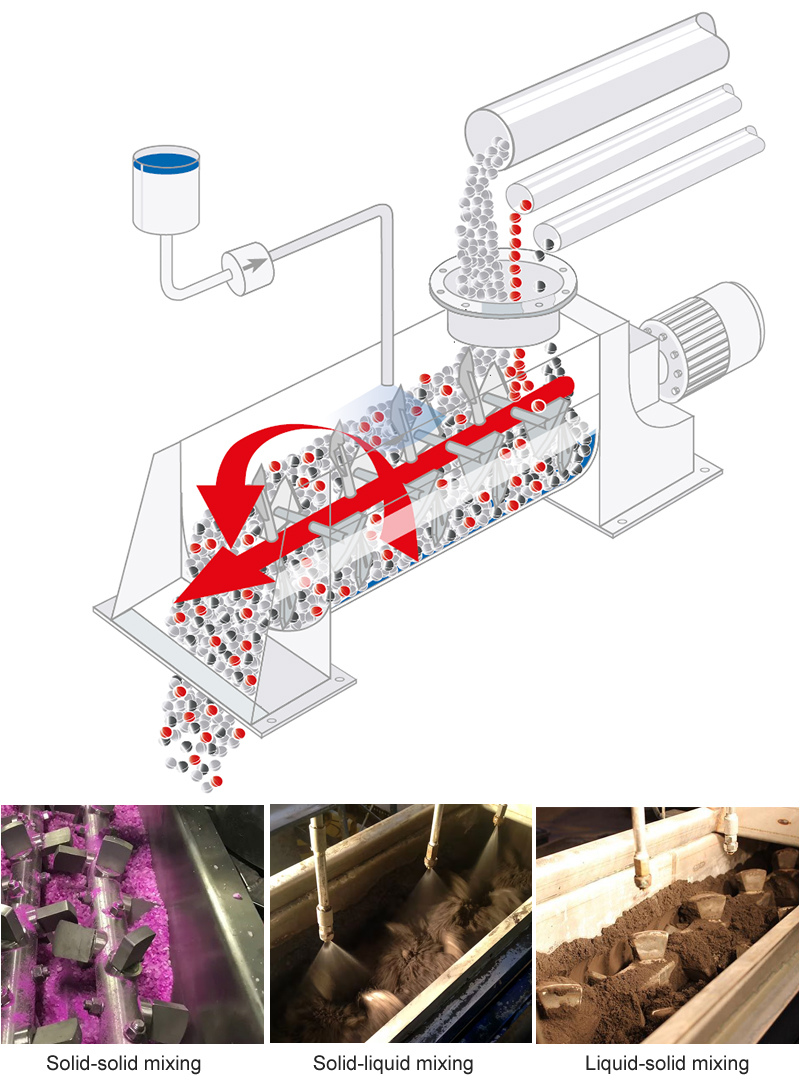

Solid-solid mixing: Product properties with very fine particles, a wide distribution of particles or variable specific density can be handled. With an optimal mixing volume to output ratio, the mixing process is gentle, fast and takes into account the different properties of the bulk material.

Solid-liquid mixing: Liquids are sprayed onto the material as chemical additives (absorbent aromas, binders). The main issue is to prevent agglomeration, absorption or binding of the liquid to the product. The mixer size, number and position of nozzles and residence time are fully customizable.

Liquid-solid mixing: Continuous mixers are suitable for mixing solid streams into larger liquid streams. For example, the preparation of viscous masses in cereal bar production or upstream filling lines for chocolate. In ceramic production, for upstream kneading or extrusion.

The working principle of a continuous mixer can be simply described as the following steps:

Feeding: Materials are continuously fed into the continuous mixer through the feeding port. Feeding can be done by gravity, conveyor belts, screw conveyors, etc.

Stirring: Continuous mixers are usually equipped with stirring devices, such as stirring paddles, spiral mixers, etc. The driving device drives the stirring device to rotate so that it stirs in the mixing chamber. The form and construction of mixing devices vary according to specific design and application requirements.

Mixing:While stirring, the materials are mixed evenly. The movement of the stirring device pushes, throws and mixes the materials, causing the materials of different components to interact and diffuse, thereby achieving the mixing effect.

Discharge: The mixed materials are continuously discharged through the discharge port. Discharging can be done by gravity, screw conveyor, extruder, etc.

By providing a continuous flow of mixed product, continuous mixers can ensure consistent and repeatable quality. Continuous mixers are more energy efficient than batch mixers, especially for large-scale operations, and many continuous mixers can be fully automated, reducing the need for manual labor.

Suitable application scenarios for continuous mixers

Large-scale production: occasions requiring high output and continuous production.

Industries with high product quality requirements: such as food, medicine, chemicals, etc.

Occasions requiring automated production: improve production efficiency and reduce labor costs.

Occasions with high viscosity or poor fluidity of materials: Continuous mixers can meet the mixing needs of such materials through special structural designs.

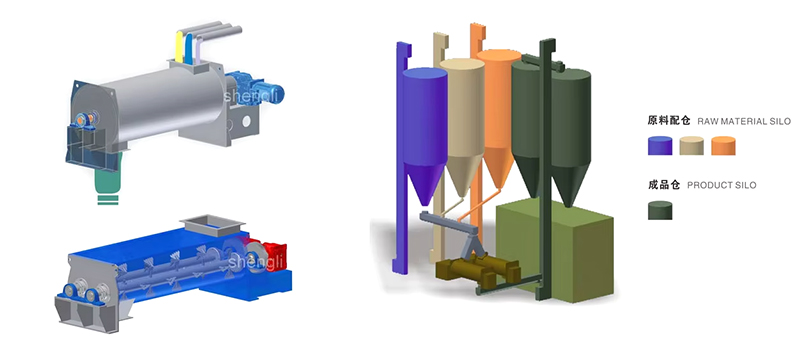

Continuous mixer configuration

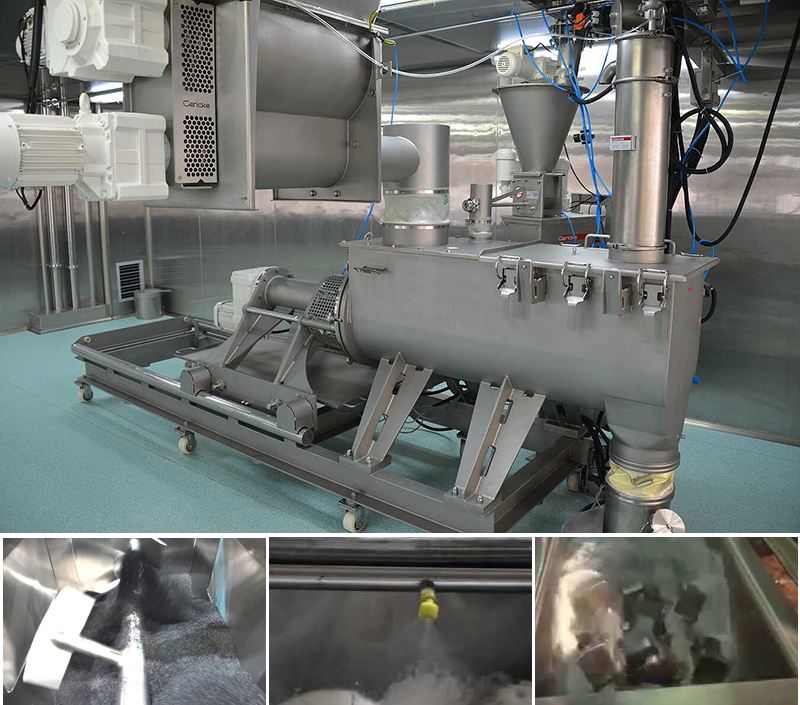

Dry / liquid mixture: The ideal solution for a mixture without lumps! This mixer is specially designed to achieve high viscosity paste mixtures or liquids with a low proportion of powders. It can be equipped with a jacket for heating or cooling the product.

Dry mix / sec: For your mixtures of dry products with different densities and sizes. It allows in particular to distribute the products irrespective of the proportions in a continuous flow of dry (0.05 to 99.95%).

Humidification: This device can continuously distribute a small proportion liquid (0.005 to 20%).

Improve product uniformity

In a continuous mixing process, material is continuously fed and discharged, so the entire production run is carried out in continuity. This leads to improved product uniformity due to the elimination of the “head” and “tail” sections associated with batch-to-batch variation.

Smaller equipment footprint

Because material is continuously moving through the unit, a continuous mixer does not need to accommodate the space requirements of an entire batch of material at once, so the mixer can be smaller. Material storage requirements are also typically less for continuous operations.

Increased production capacity

The continuous processing of material without the necessary stops associated with batches reduces the overall time required to reach production goals, allowing more product to be produced in the same amount of time. Similarly, producers who switch to a continuous line often see a reduction in labor requirements.

Automation

Continuous mixing also facilitates the integration of a controls system. Mixers are easily automated with various data points being tracked and displayed on a human machine interface (HMI), even allowing for real-time adjustment.

| Model | LHY-0.25 | LHY-0.5 | LHY-1 | LHY-1.5 | LHY-2 | LHY-3 | LHY-4 | LHY-6 | LHY-8 | LHY-10 |

| One-time mixing (kg) | 100-150 | 200-300 | 400-600 | 600-900 | 800-1000 | 1200-1800 | 1600-2400 | 2400-3600 | 3200-4800 | 4000-6000 |

| Mixing time (min) | 8-20 | 8-20 | 8-20 | 8-20 | 8-20 | 8-20 | 8-20 | 8-20 | 8-20 | 8-20 |

| Mixing speed (r/min) | 60 | 55 | 45 | 40 | 35 | 25 | 25 | 20 | 15 | 15 |

| Motor power (kw) | 3-5.5 | 4-11 | 7.5-15 | 11-18.5 | 15-22 | 18.5-30 | 22-37 | 37-55 | 37-55 | 45-75 |

| Weight (kg) | 500 | 900 | 1800 | 2500 | 3200 | 4100 | 5100 | 6300 | 7500 |

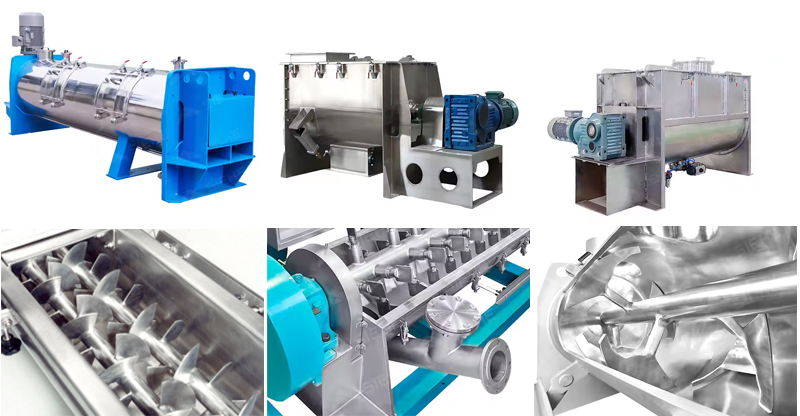

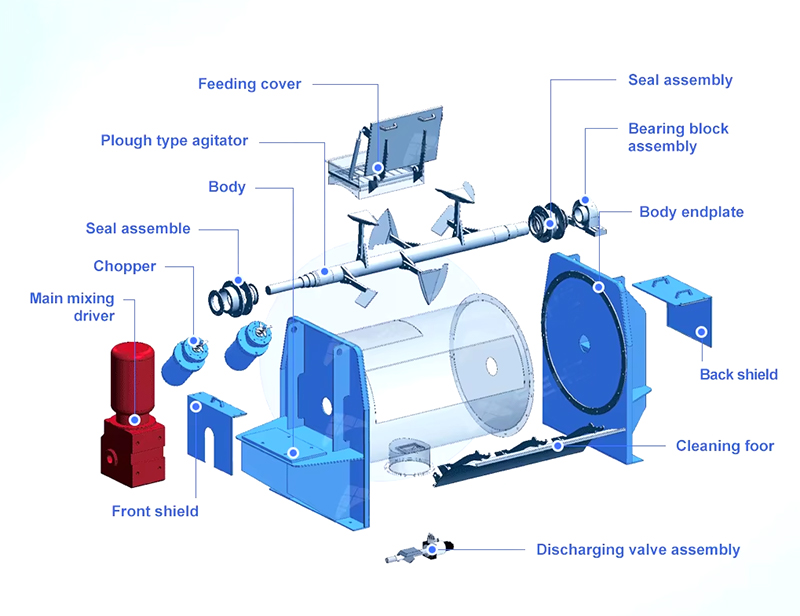

A typical continuous mixer consists of:

Feeders: These devices introduce ingredients into the mixer at a controlled rate.

Mixing chamber: This is the main section where the ingredients are blended. It can be designed in various configurations, such as horizontal or vertical, depending on the specific application.

Mixing elements: These elements, such as paddles, blades, or screws, agitate and distribute the ingredients within the mixing chamber.

Discharge system: This system removes the mixed product from the mixer.

Batch mixers and continuous mixers are two different types of mixing equipment. They have some differences in mixing methods, working methods and applicable scenarios.

| Comparative Item | batch mixer | continuous mixer |

|

|

|

| Mixing method | A batch mixer is a batch mixing equipment that puts a certain amount of materials into the mixer at one time for mixing and stirring. The mixing process is usually carried out for a set time, then stopped, and the mixed materials are taken out. Mixing this way is discrete and done in one go. | A continuous mixer is a mixing equipment with continuous feeding and continuous discharging. The materials are continuously supplied to the mixer, and after continuous stirring and mixing, the mixed materials are continuously discharged. The mixing process is continuous and requires no downtime or interruptions. |

| Way of working | The batch mixer requires loading and unloading operations between each mixing cycle, that is, the equipment needs to be shut down and cleaned before the next mixing cycle. This working method is suitable for mixing needs of small batches and frequent changes of materials. | Continuous mixer can realize continuous feeding, mixing and discharge without downtime or intermittent. It can handle large amounts of materials continuously and is suitable for scenarios that require efficient continuous production. |

| Applicable scene | Batch mixers are suitable for small-scale production and flexible mixing needs. It is often used in laboratories, small batch production or scenarios that require frequent replacement of materials. For example, batch mixers are often used for batter mixing and condiment mixing in the baking industry. | Continuous mixer is suitable for large-scale production and continuous production needs. It is commonly used in large-scale production lines in chemical, food, pharmaceutical and other industries. For example, chemical reactions in large chemical plants, sauce mixing in food plants, and cement mixing in building materials plants often use continuous mixers. |

| Advantages | Good mixing effect, suitable for small batch production, easy to clean; suitable for occasions with high requirements for mixing quality. | Large-scale production, high production efficiency, simple operation, continuous production, suitable for occasions with high requirements for production efficiency. |

1. material selection

Material can be carbon steel, manganese steel, ss304, 316L and 321; besides, different material can also be used between the part contact with the raw material and the parts don’t contact with the raw material. Surface treatment for stainless steel include sandblasting, wiredrawing, polishing, mirror polishing, all can be used in different parts of a mixer.

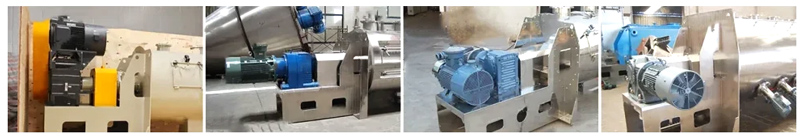

2. driven unit

The driven unit, power and output speed are varied according to different raw material, starting method, and processing. Options for motor: general motors, explosion-proof motors, variable frequency motor, high efficiency and energy saving motor. Commonly used reducers: R-series, K-series, and F-series gear box; cycloidal reducer, universal gear reducer, planetary gear reducer.Commonly motor gearbox connection: direct connection, pulley connection, hydraulic coupler connection.

3. mixing unit

The plow heads in the plough shear mixer can be dismountable, which is convenient for replacement. Wear-resistance treatment is done on the plow, making the plow more durable to the severe wear conditions. Different main shaft agitators can be equipped according to the properties of raw materials.Main shaft agitators: ordinary plough, saw-toothed plough, and shaver-shaped paddle; High speed chopper: multiple-piece cross blade, double-piece lotus blade.

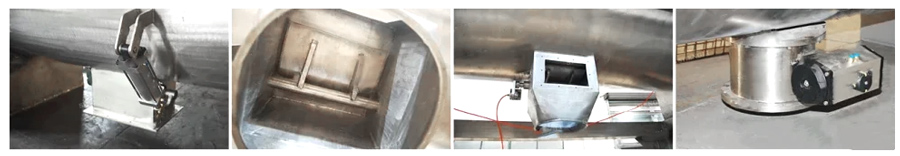

4. discharging unit

Standard valve for horizontal plough shear mixer is pneumatic planar flap valve. When close the valve, the planar flap match the mixing barrel perfectly, this makes no mixing dead zone and better mixing effect. The drive types of valve are Manual, pneumatic,and electric. Valves for option: powder spherical valve, cylinder valve, plum-blossom dislocation valve, butterfly valve, rotary valve etc.

5. auxiliary components

Mixer is equipped with many auxiliary components, like steam coil jacket, honeycomb pressure jacket, medium circulation jacket,sampling valve, high speed chopper, temperature sensor, weighing system, dust removal system and so on. Different heat medium requires different jacket, it can be used for heating and cooling, while, the temperature should be within 250 Celsius degree. If a small quantity of liquid is required during mixing, spraying or atomizing unit is necessary in order to mix the liquid evenly with the main ingredient. The liquid-adding system is basically composed by the three parts: pressure source, liquid storage pot and spraying nozzles.

6. shaft sealing

Three types of main shaft sealing for mixer: packing sealing, combined type air-purged sealing, mechanical sealing according to different material.

| Industry | Mixed materials | Specific gravity (approx.) | Mixing amount per time | Practical Uses |

| Food | Flour, sugar, butter, eggs, yeast, etc. | 0.6-0.8 g/cm³ | 500kg/h | Continuous mixing of biscuit dough ensures the uniformity and consistency of the dough and improves the taste and quality of the biscuits. |

| Chemicals | Polyethylene, polypropylene, masterbatch, antioxidants, etc. | 0.9-1.1 g/cm³ | 1000kg/h | Continuous mixing of plastic particles ensures the uniform dispersion of various components and improves the performance and appearance of plastic products. |

The above cases are only examples. The application range of continuous mixers is very wide. You can choose the appropriate equipment according to different material properties, production scale and process requirements.

When choosing a continuous mixer, you need to consider the following factors:

Material properties: material particle size, density, viscosity, fluidity, etc.

Mixing requirements: mixing uniformity, mixing time, mixing accuracy, etc.

Production scale: processing volume per hour.

Environmental conditions: temperature and humidity of the working environment, etc.

Dahan focuses on the research and development of mixers. Its products have compact structure, reliable performance, energy saving and high efficiency, and power coverage of 90w-1000kw, which can meet the production needs of different scales. Its mixers can adopt a variety of sealing methods and rich types of paddles. They are widely used in many industries such as food, medicine, and chemical industry. In terms of price, due to the variety of product models and configurations, from basic models to high-end customized models, the price span is large, roughly ranging from $2,000.00-$10,000.00. If you need it, please feel free to contact us for a quotation!

Address:China,Yanjin county forest park gate to the west 1000 meters north road.