Powder for continuous mixer achieves uninterrupted homogeneous mixing of powder materials through a dynamic, continuous feeding, mixing, and discharging integrated process. This completely breaks away from the intermittent "feed-mix-discharge" operation mode of traditional batch mixers, significantly improving production efficiency. The mixing uniformity remains stable at over 99%, with no dead zones or residues during the mixing process. Its key feature is "simultaneous feeding and discharging," allowing seamless integration with front-end feeding equipment and back-end granulation/packaging equipment to build a complete continuous powder production line.

Our Powder for Continuous mixer also supports comprehensive customization. The mixing speed and internal structure can be adjusted according to powder characteristics (such as particle size, specific gravity, and moisture content). Processing capacity can be customized to meet production needs (from hundreds of kilograms to tens of tons per hour). It can also be equipped with temperature control, dust removal, and liquid spraying modules, adapting to the continuous production needs of multiple industries such as chemical, food, pharmaceutical, and building materials, providing enterprises with flexible and reliable solutions for large-scale, automated powder mixing.

We offer Powder for Continuous Mixers with multiple technology approaches, including dual-shaft paddle mixers, vertical ribbon mixers, and gravity diffusion mixers, covering the needs of the entire industry, including food, chemical, and new materials. Our equipment supports flexible customization from small-batch laboratory production to large-scale industrial production.

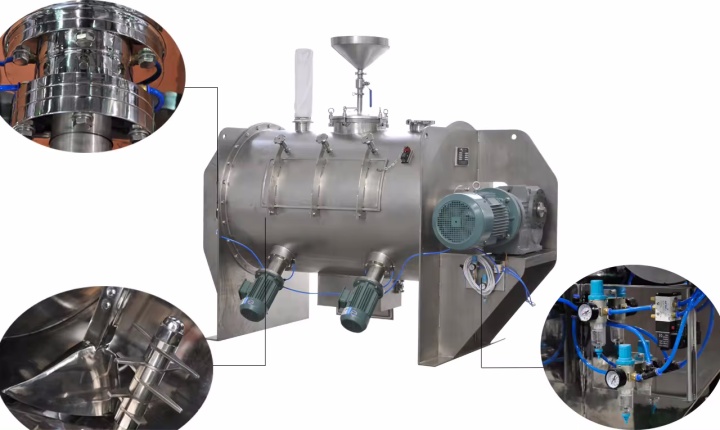

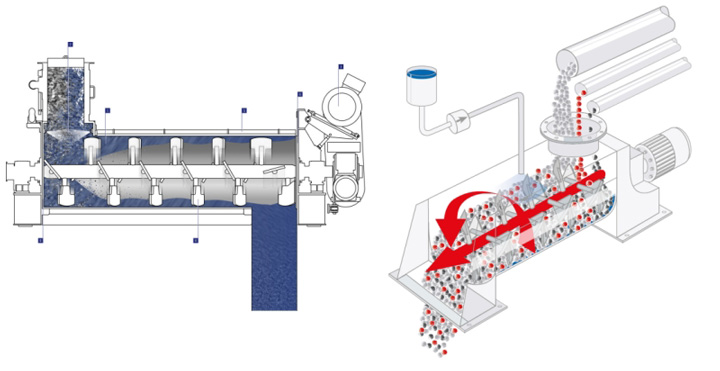

Paddle continuous mixer: The rotating blades produce shear, convection and turbulence to achieve rapid mixing of materials. Suitable for a variety of powders, including materials with poor fluidity or easy to agglomerate.

Ploughshare Continuous Mixer: It uses a high-speed rotating ploughshare-shaped agitator to generate strong turbulence and shear force to achieve efficient mixing. It is suitable for powders with large mixing ratio differences and complex components.

Fluidized Bed Mixer The powder particles are suspended by airflow and collide and rub against each other to achieve uniform mixing. It is suitable for mixing fine powders and ultrafine powders, with the characteristics of fast mixing speed and good uniformity.

Rotor-Stator Continuous Mixer: It uses the shearing effect between the high-speed rotating rotor and the fixed stator to achieve mixing. It is suitable for mixing occasions that require high shear force, such as mixing powders with liquids or dispersing agglomerated powders.

A powder for continuous mixing breaks through the limitations of traditional batch mixing, enabling continuous, uninterrupted production and significantly improving efficiency. Precise feeding and speed control ensures uniform mixing. The equipment has a compact structure, small footprint, stable operation, and low energy consumption.

Continuous operation mode: Unlike traditional batch mixers that require frequent stops for loading and unloading, the powder for continuous mixing and discharging can achieve uninterrupted mixing and discharging. The material continuously flows and is mixed within the equipment, greatly shortening the production cycle.

Rapid mixing capability: Its optimized mixing structure, such as dual-shaft or multi-shaft impellers or ribbons, can quickly shear, disperse, and tumble powder materials, enabling them to reach a uniform mixing state in a short time.

High uniformity: By precisely controlling the speed, shape, and arrangement of the mixing impellers, as well as the residence time of the material within the equipment, the powder for continuous mixing ensures full contact and mixing of powder materials with different components.

Precisely adjustable: Operating parameters, such as feed rate, mixing speed, and discharge rate, can be flexibly adjusted according to the characteristics and mixing requirements of different materials.

Smooth integration: Seamlessly connects with upstream material conveying equipment (such as screw conveyors and pneumatic conveying systems) and downstream packaging and forming equipment to form a complete automated production line.

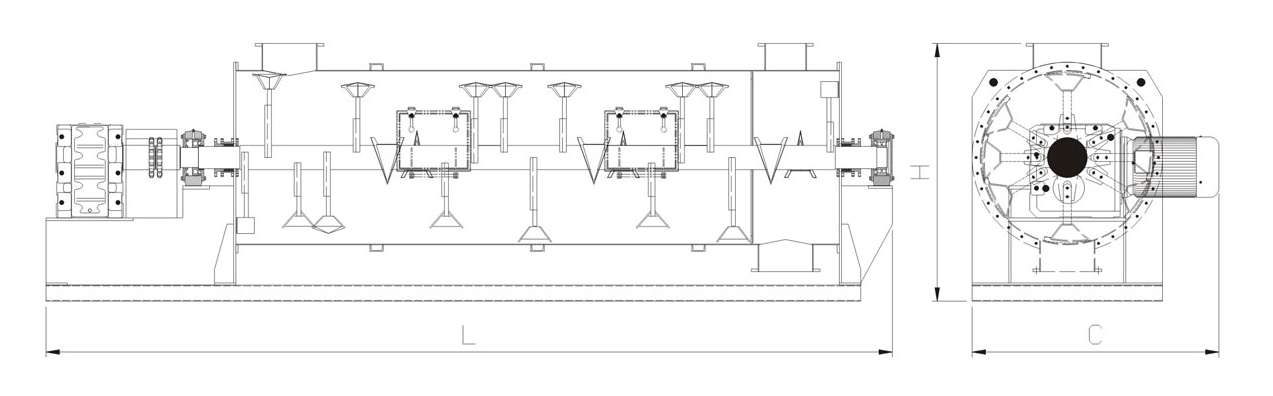

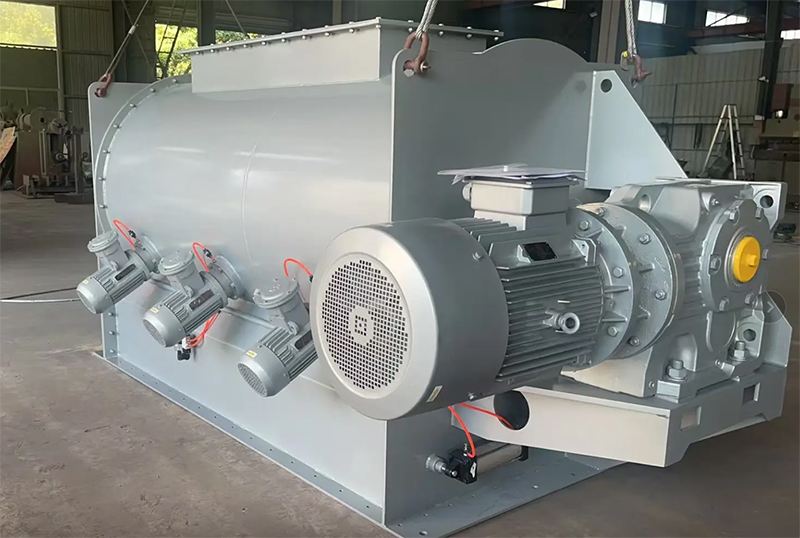

The Powder for Continuous Mixer consists of a horizontal drum, a twin-shaft mixing system, a drive unit, and infeed/discharge mechanisms. Its core mechanism achieves fluidized mixing through the three-dimensional motion of impellers/ribbons, and it is equipped with a variable frequency motor and adjustable baffles to precisely control residence time.

Mixing Chamber: A mixing space used to hold raw materials.

Feeding system: Continuously feed raw materials into the mixing chamber.

Stirring device: used to mix raw materials to ensure uniform mixing.

Discharge device: continuously discharges the mixed product.

Control system: used to monitor and adjust various parameters during the mixing process.

The working principle of Powder for continuous mixer is to continuously feed raw materials into the mixing chamber for mixing, and then continuously discharge the mixed product. The raw materials are continuously rolled and impacted in the mixing chamber through the action of the stirring device, thereby achieving uniform mixing. The control system can accurately adjust parameters during the mixing process, such as mixing time, speed, temperature, etc., to ensure the accuracy and stability of mixing.

| Model | LHY-0.25 | LHY-0.5 | LHY-1 | LHY-1.5 | LHY-2 | LHY-3 | LHY-4 | LHY-6 | LHY-8 | LHY-10 |

| One-time mixing (kg) | 100-150 | 200-300 | 400-600 | 600-900 | 800-1000 | 1200-1800 | 1600-2400 | 2400-3600 | 3200-4800 | 4000-6000 |

| Mixing time (min) | 8-20 | 8-20 | 8-20 | 8-20 | 8-20 | 8-20 | 8-20 | 8-20 | 8-20 | 8-20 |

| Mixing speed (r/min) | 60 | 55 | 45 | 40 | 35 | 25 | 25 | 20 | 15 | 15 |

| Motor power (kw) | 3-5.5 | 4-11 | 7.5-15 | 11-18.5 | 15-22 | 18.5-30 | 22-37 | 37-55 | 37-55 | 45-75 |

| Weight (kg) | 500 | 900 | 1800 | 2500 | 3200 | 4100 | 5100 | 6300 | 7500 |

The continuous powder mixer, with its advantages of continuous and high-efficiency mixing, is widely used in large-scale powder production scenarios across multiple industries. Its continuous operation significantly improves production efficiency and ensures stable mixing quality.

Chemical Industry: It can be used for the continuous mixing of materials such as plastic masterbatches, coating powders, and dye auxiliaries. It can be integrated with extrusion granulation equipment to achieve integrated production from raw material mixing to finished product granulation.

Food Industry: It is suitable for processes such as flour additive mixing, seasoning powder preparation, and nutritional powder homogenization, meeting the dual requirements of hygiene and efficiency in food production. Food-grade stainless steel can be selected as the material.

Pharmaceutical Industry: It is used for the continuous mixing of pharmaceutical excipients and traditional Chinese medicine powders. Through customized closed-chamber and anti-cross-contamination designs, it meets GMP certification standards.

Building Materials Industry: It can process raw materials such as cement additives, dry mortar, and putty powder. Combined with an automatic feeding system, it enables large-scale continuous mixing.

Feed Industry: It is suitable for the continuous preparation of powder premixes for livestock and poultry feed and aquatic feed, ensuring uniform distribution of nutrients.

Batch mixers and continuous mixers represent two completely different production logics. Batch mixers operate on a batch basis, completing material mixing in a fixed time, flexibly adapting to small-batch, multi-formula scenarios; while continuous mixers are based on streamlined operations, achieving uninterrupted input and output of materials, better meeting the needs of large-scale, standardized production.

| Feature | Batch Mixer | Continuous Mixer |

| Operation Mode | Intermittent operation; materials are loaded, mixed, and discharged in batches | Continuous operation; materials are fed, mixed, and discharged simultaneously |

| Application | Small-scale, multi-product, or frequent formula changes | Large-scale, single-product, high-efficiency production |

| Mixing Uniformity | High | Slightly lower, but can be improved with optimized design and parameters |

| Mixing Efficiency | Lower | Higher |

| Production Capacity | Smaller | Larger |

| Automation Level | Lower | Higher |

| Equipment Cost | Lower | Higher |

| Floor Space | Smaller | Larger |

| Flexibility | High; easy to change formulas and clean | Low; suitable for fixed-formula continuous production |

| Material Adaptability | Less demanding on material flowability | More demanding on material flowability |

| Maintenance and Cleaning | Relatively simple | Relatively complex |

Many industry clients choose our powder continuous mixers due to their strong customization capabilities. With diverse models and professional services, we precisely match the needs of different industry clients, gaining widespread recognition.

Solid Beverage Processing: Traditional batch mixers suffer from low efficiency and insufficient mixing uniformity, resulting in poor batch stability. After ordering multiple dual-power mixers, this client achieved continuous dynamic mixing of powders and additives through a twin-shaft spiral structure, increasing mixing uniformity to 99.5%, single-batch processing capacity to 2 tons, and production efficiency to 40%.

Pigment Mixing: For handling highly corrosive materials, the equipment utilizes 316L stainless steel with an acid-resistant coating, and the sealing structure has been upgraded to a double-layer mechanical seal to effectively prevent material leakage. In actual operation, the equipment continuously processed chlorine-containing dyes for 12 months without corrosion, reducing maintenance costs by 60%, and shortening mixing time from 45 minutes with traditional equipment to 18 minutes.

Lithium Battery Separator Materials: Used for continuous mixing of cathode material precursors. The equipment achieves uniform dispersion of nano-sized particles through frequency conversion control and three-dimensional eddy current technology, with particle size deviation controlled within ±2%.

The price of powder for continuous mixers varies depending on the model, configuration, and production scale, presenting a multi-tiered price range. Basic small-scale equipment typically starts at $5000 and is suitable for laboratory or small-scale production scenarios. These models often employ a single-shaft mixing structure to meet basic mixing needs. Continuous mixers with intelligent control systems and explosion-proof designs, supporting precise proportioning of multiple materials and continuous operation, will gradually increase in price. A specific price list will be provided based on your production requirements to match the appropriate model.

Dahan Machinery's Powder for Continuous Mixer boasts a standardized production base and a senior technical team. The core of the equipment utilizes a precision mixing structure and a continuous feeding and discharging system, achieving a mixing uniformity of over 99% and a production capacity ranging from hundreds of kilograms to tens of tons per hour. Full-process non-standard customization is supported, allowing adjustments to the chamber structure and mixing speed based on customer material characteristics and production capacity requirements. It can also be equipped with temperature control, dust removal, and liquid spraying modules, making it suitable for various industries such as chemical, food, and pharmaceutical. Products undergo rigorous quality testing, and we provide one-stop service including solution design, commissioning, and after-sales support. With its stable performance and customization advantages, we have created efficient continuous powder mixing production lines for thousands of companies both domestically and internationally.

In general, powder for continuous mixer, as an important industrial equipment, provides efficient and precise mixing solutions for various industries. Its superior performance and functions make it an indispensable part of many production processes, bringing convenience and benefits to production companies. As a type of continuous mixer, powder for continuous mixer is widely used. If you are interested in continuous mixer, please click on our product page to view it.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.