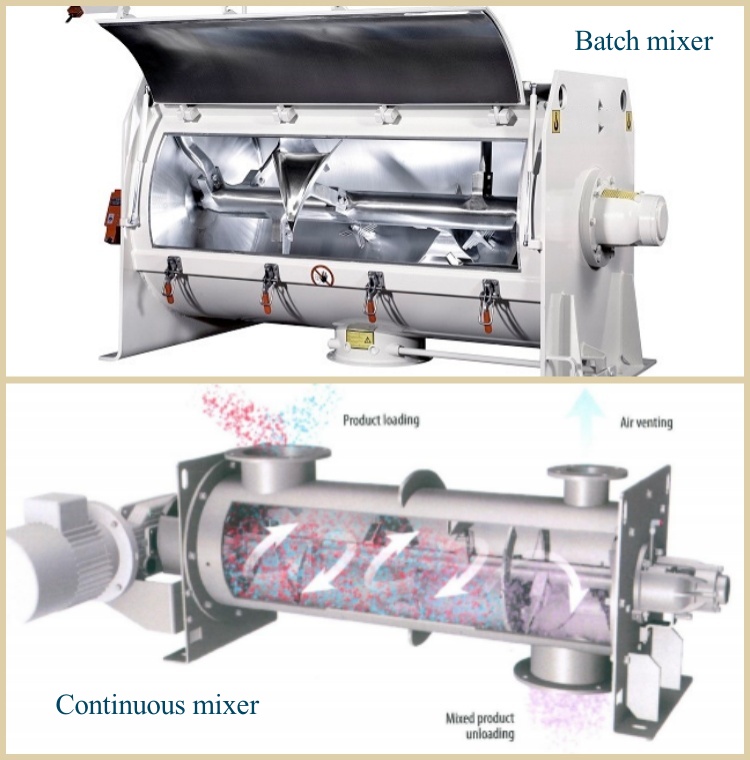

Batch mixer and continuous mixer are two commonly used mixing equipment in industrial production. There are some significant differences between them in terms of working principle, scope of application, mixing effect, production efficiency, etc. The following will introduce the difference between batch mixer mixer and continuous mixer in detail:

Intermittent mixer: Batch mixer is a batch mixing equipment. The working principle is to put a certain amount of raw materials into the mixing chamber, mix and stir until the desired mixing effect is achieved and then stop. After the mixing is completed, it is necessary to stop the machine to take out the mixture and clean the equipment before the next batch of mixing can be carried out.

Continuous mixer: Continuous mixer is a continuously running mixing equipment. The working principle is to continuously add raw materials into the mixing chamber, and the mixed materials are continuously stirred and mixed, and finally the mixed products are continuously output. Continuous mixers can achieve continuous production without stopping to take out the mixture.

Batch mixer: It is suitable for occasions where small batches of raw materials need to be mixed, such as laboratories, small-scale production lines, etc. Because it is a batch operation, it is suitable for production environments with high requirements for mixed materials.

Continuous mixer: suitable for large-scale production lines, can achieve continuous production, and is suitable for occasions with high production efficiency requirements. Continuous mixers are usually used for large-scale production and can improve production efficiency.

Batch mixer: Due to batch operation, intermittent mixers can control the mixing process more finely, with better mixing effect, and are suitable for occasions with high mixing quality requirements.

Continuous mixer: Due to continuous operation, the mixing effect may be relatively uniform but not as fine as intermittent mixers. Suitable for occasions with general requirements for mixing effect.

Batch mixer: Due to batch operation, the production efficiency is relatively low, and it is necessary to wait for each batch of mixing to be completed before the next batch of mixing can be carried out, which is suitable for small-scale production.

Continuous mixer: Due to continuous operation, the production efficiency is high, continuous production can be achieved, and it is suitable for large-scale production lines, which can improve production efficiency.

Batch mixer: Due to batch operation, cleaning and maintenance are relatively simple, and the equipment can be cleaned and maintained after each mixing is completed.

Continuous mixer: Due to continuous operation, cleaning and maintenance are relatively complicated, and regular cleaning and maintenance are required during the production process to ensure the normal operation of the equipment.

In summary, there are obvious differences between batch mixers and continuous mixers in terms of working principle, scope of application, mixing effect, production efficiency, maintenance and cleaning. The selection of suitable mixing equipment depends on factors such as production scale, mixing requirements and production efficiency. When selecting mixing equipment, enterprises should make comprehensive considerations based on actual needs to improve production efficiency and product quality.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.