Rotary continuous mixer is a device used to continuously mix various powdery, granular or viscous materials in industrial production. It usually consists of a mixing barrel, agitator, transmission device, feed port and discharge port and other components. Rotary continuous mixers can be widely used in chemical, food, pharmaceutical and other industries to produce various mixtures, such as granules, powders, granular mixtures, etc., to ensure product quality and production efficiency. Its continuity and efficiency make it one of the indispensable and important equipment in many production lines.

The working principle of the rotary Continuous mixer is based on the mixer rotating in the mixing barrel to mix materials with different components. The materials are continuously put into the mixing cylinder through the feed port. After the mixer mixes them evenly, the mixed materials are continuously discharged from the discharge port.

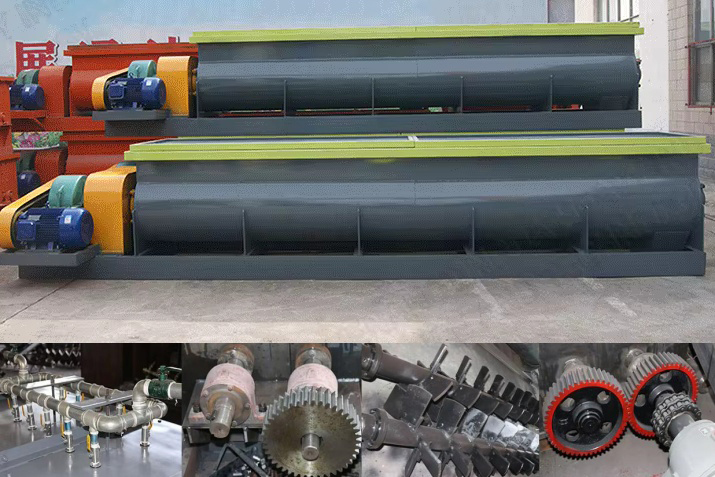

The rotary continuous mixer is mainly composed of the following parts:

Mixing chamber: usually a cylindrical or conical structure placed horizontally or tilted, with stirring elements inside.

Stirring shaft: select the appropriate type according to the characteristics of the material, such as screw, paddle, belt, etc.

Motor: Provide power to drive the stirring shaft to rotate.

Reducer: Reduce the motor speed and increase the torque.

Feeding device: such as screw conveyor, vibrating feeder, etc., to ensure uniform feeding of materials.

Discharging device: such as rotary valve, star discharger, etc., to control the discharging speed.

Electric control cabinet: Control motor start, stop, speed, etc.

PLC controller: realize automatic control, and can set parameters such as mixing time and speed according to needs.

Continuous production: Rotary continuous mixer can realize continuous feeding and continuous discharging, improving production efficiency.

Uniform mixing: The mixer is reasonably designed to fully mix materials with different components to ensure uniform mixing.

Wide range of applications: Rotary continuous mixer is suitable for mixing a variety of powdery, granular or viscous materials.

Easy operation: Rotary continuous mixers have a simple structure and are easy to operate and maintain.

Energy saving: The transmission device is reasonably designed to save energy consumption.

Rotary continuous mixers are widely used in many industries, including but not limited to:

Chemical industry: Rotary continuous mixers are used for mixing granules and powders.

Food industry: Rotary continuous mixers are used for mixing food additives, seasonings, etc.

Pharmaceutical industry: Rotary continuous mixers are used for mixing pharmaceutical ingredients.

Building materials industry: Rotary continuous mixers are used for mixing cement, lime and other materials.

Agricultural field: Rotary continuous mixers are used for mixing feed, fertilizer, etc.

In order to ensure the normal operation of rotary continuous mixers, regular maintenance work is required, including:

Cleaning: Clean the mixing drum and agitator regularly to prevent material residue.

Lubrication: Keep the transmission lubricated and reduce wear.

Inspection: Regularly check the operation of each component to detect and deal with problems in a timely manner.

Rotary continuous mixers, as an important industrial mixing equipment, play a key role in modern production. Through reasonable design and operation, it can effectively mix different materials, improve production efficiency, and ensure product quality. When selecting and using, users should select equipment with appropriate specifications based on actual needs and production conditions, and strictly abide by operating procedures to ensure normal operation and safe production of the equipment.

Generally speaking, a high-quality rotary continuous mixer can work continuously for hundreds of hours or even longer under normal operation and maintenance conditions, but its working time depends on many factors and it is impossible to give an absolute answer. The following are some key influencing factors:

Equipment structure: Equipment with reasonable design and solid structure can withstand longer continuous operation.

Material quality: Equipment made of high-quality materials is more wear-resistant and corrosion-resistant, and has a longer service life.

Manufacturing process: Sophisticated manufacturing process can ensure the accuracy and reliability of the equipment and reduce the failure rate.

Material properties: The particle size, density, viscosity, corrosiveness and other characteristics of the material will affect the degree of wear of the equipment.

Mixing ratio: The mixing ratio of different materials will affect the load and energy consumption of the equipment.

Mixing uniformity requirements: Higher mixing uniformity requirements may require longer mixing time.

Operation specifications: Use the equipment strictly in accordance with the operating procedures to avoid overload operation and misoperation.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.