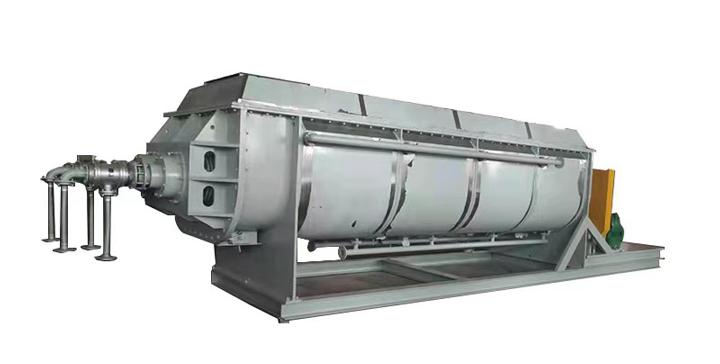

Continuous mixer is a device used to continuously mix various powdery, granular or viscous materials in industrial production. It rotates in the mixing barrel through a stirrer to fully mix materials of different properties or particle sizes. Different from batch mixers, continuous mixers can realize continuous feeding and discharging of materials, improve production efficiency and ensure mixing uniformity. This kind of equipment is widely used in chemical, food, pharmaceutical and other industries. It is easy to operate and can meet the needs of different industries for mixing effect and production efficiency.

A continuous mixer usually consists of a mixing barrel, a stirrer, a transmission device, an inlet and an outlet and other components. The working principle is to fully mix materials of different properties or particle sizes through the stirrer rotating in the mixing barrel. Materials are continuously put into the mixing cylinder through the feed port. After mixing, the mixture is continuously discharged through the discharge port, thus realizing a continuous production process.

This kind of equipment has a wide range of applications in industrial production.

In the chemical industry, continuous mixers are often used to mix powders, granules or granules to produce chemical products or pharmaceuticals.

In the food industry, continuous mixers can be used to mix various food raw materials, such as flour, powdered sugar, etc., to produce food products.

In the building materials industry, continuous mixers can be used to mix cement, lime and other raw materials to produce building materials.

One of the advantages of a continuous mixer is that it is easy to operate. You only need to set appropriate parameters to achieve a continuous mixing process. In addition, due to continuous feeding and continuous discharging, downtime during the production process can be effectively reduced and production efficiency improved. At the same time, the continuous mixer can ensure the uniformity of the mixed materials, avoid differences between different batches, and ensure stable product quality.

However, continuous mixers also have some limitations. For example, some special materials may require additional processing or equipment to achieve effective mixing. In addition, cleaning and maintenance of continuous mixers also require a certain amount of manpower and time.

Overall, continuous mixers, as an important industrial equipment, play a key role in various industries. With the continuous development of industrial technology, the performance and functions of continuous mixers are also constantly improving, providing more convenient and reliable solutions for production in various industries. If you want to learn more about the continuous mixer, you can view the continuous mixer product page, which will provide a more detailed introduction to the continuous mixer.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.