Horizontal ribbon mixer for poultry feed is a specialized device designed for mixing poultry feed. Its core function is to precisely mix basic raw materials such as corn, soybean meal, and bran with additives such as vitamins, minerals, and amino acids to ensure that each portion of feed is nutritionally balanced and meets the nutritional needs of chickens, ducks, geese, and other poultry at different growth stages.Horizontal ribbon mixer for poultry feed usually consists of horizontal barrel, spiral blade, transmission device and control system. The spiral blades rotate in the horizontal barrel to force convection mixing of the raw materials to ensure even distribution of feed ingredients.

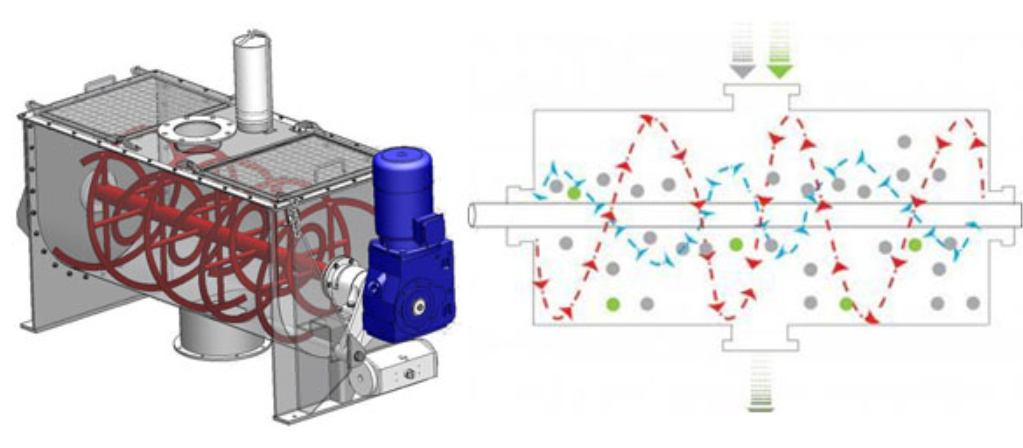

The horizontal ribbon mixer uses a double-layered ribbon design to create three-dimensional convection mixing. It efficiently processes raw materials such as corn, soybean meal, and bone meal, ensuring uniform distribution of vitamins, minerals, and other trace components.

Mixing various raw materials: Evenly mix various granular and powdery raw materials such as grains, soybean meal, vitamins, minerals, etc. to ensure the comprehensive nutrition of the feed.

Additive mixing: Mix additives such as antibiotics, enzyme preparations, etc. with the main raw materials to improve the nutritional value and effect of the feed.

Color and aroma homogenization: Color and aroma agents are evenly mixed into the feed through a mixer to increase the attractiveness of the poultry to the feed.

Drug Mixing: Mix drugs evenly into feed to prevent and treat poultry diseases.

The Horizontal ribbon mixer for poultry feed creates a convection circulation through the counter-rotating double-layer ribbons, which enables powders, granules and liquid additives to be uniformly mixed throughout the entire volume within 2-6 minutes.

Horizontal barrel structure: Horizontal ribbon mixer usually consists of a horizontal mixing barrel with spiral blades inside.

Function of spiral blade: In the horizontal barrel, there are one or more spiral blades fixed on the main shaft. When the main shaft rotates, the spiral blades also rotate.

Raw material mixing process: When the horizontal ribbon mixer is started, the spiral blades transport the raw materials from one end of the barrel to the other.

Mixing time control: Mixing time is usually controlled by a control system to ensure that the raw materials are fully mixed to achieve the required mixing level.

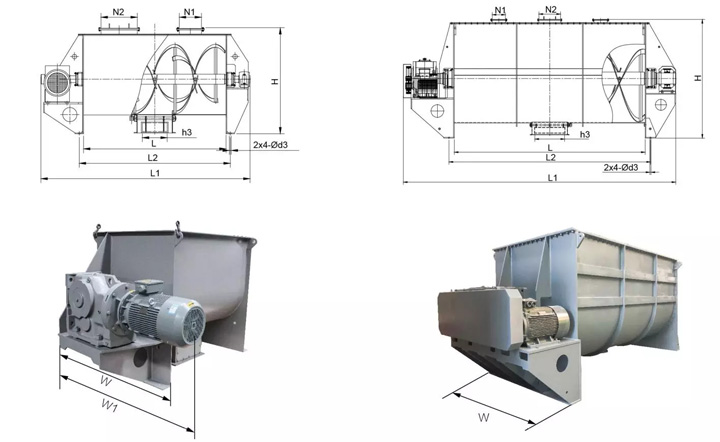

| Model | LHY-0.25 | LHY-0.5 | LHY-1 | LHY-1.5 | LHY-2 | LHY-3 | LHY-4 | LHY-6 | LHY-8 | LHY-10 |

| One-time mixing (kg) | 100-150 | 200-300 | 400-600 | 600-900 | 800-1000 | 1200-1800 | 1600-2400 | 2400-3600 | 3200-4800 | 4000-6000 |

| Mixing time (min) | 8-20 | 8-20 | 8-20 | 8-20 | 8-20 | 8-20 | 8-20 | 8-20 | 8-20 | 8-20 |

| Mixing speed (r/min) | 60 | 55 | 45 | 40 | 35 | 25 | 25 | 20 | 15 | 15 |

| Motor power (kw) | 3-5.5 | 4-11 | 7.5-15 | 11-18.5 | 15-22 | 18.5-30 | 22-37 | 37-55 | 37-55 | 45-75 |

| Weight (kg) | 500 | 900 | 1800 | 2500 | 3200 | 4100 | 5100 | 6300 | 7500 |

When the Horizontal ribbon mixer for poultry feed is working, the materials are first fed into the drum according to the recipe. The double-layer ribbon rotates in different directions. The outer layer of the ribbon pushes the materials and moves counterclockwise along the drum wall, while the inner layer of the ribbon brings the materials to the center clockwise, forming a convection circulation.

Feeding: First, put the various raw materials to be mixed into the horizontal barrel of the horizontal ribbon mixer through the feeding port.

Start the equipment: Start the mixer, let the main shaft and spiral blades start to rotate, and start the mixing work.

Mixing process: Under the action of the spiral blades, the raw materials are continuously tumbling and convection in the barrel to achieve uniform mixing.

Stop equipment: Stop the mixer when mixing reaches a preset time or mixing level.

Discharging: Open the discharging port and take out the mixed feed ingredients for subsequent processing or packaging.

The Horizontal ribbon mixer for poultry feed features a U-shaped barrel with double spiral blades. The outer spiral gathers the material while the inner spiral distributes it. This mixer achieves efficient mixing of powders and liquids through forced convection. The pneumatically operated wide-opening discharge port ensures no residue.

Poultry feed horizontal ribbon mixer is mainly composed of the following parts:

Mixing tank: usually made of carbon steel or stainless steel, corrosion-resistant and easy to clean, ranging from hundreds of liters to tens of cubic meters, can be selected according to the scale of breeding.

Mixing shaft: horizontally placed, supported by bearings at both ends.

Spiral ribbon: welded on the mixing shaft, usually a double-layer design, the outer ring spiral ribbon pushes the material from both ends to the middle, and the inner ring spiral ribbon pushes the material from the middle to both ends to form convection mixing.

Motor: Provides power to drive the mixing shaft to rotate.

Feed inlet: located at the top of the mixing tank, used to add materials.

Discharge port: located at the bottom of the mixing tank, used to discharge the mixed feed.

Electric control cabinet: Controls the start, stop, speed, etc. of the motor.

The Horizontal ribbon mixer for poultry feed provides rapid mixing in 2-6 minutes. Its double-layer ribbon structure achieves highly uniform mixing of powdered/semi-fluid materials, making it suitable for the production of complete feed for chickens, ducks, geese, and other animals.

Uniform mixing: The horizontal ribbon mixer adopts the principle of forced convection mixing to ensure that each particle is fully mixed to avoid unevenness in the feed.

High efficiency and energy saving: The equipment has reasonable structure and high mixing efficiency, saving energy and time costs.

Easy to operate: The control system is intelligent, easy to operate, and suitable for various production scenarios.

Reliable and stable: The manufacturing materials are of high quality, wear-resistant and corrosion-resistant, ensuring long-term stable operation of the equipment.

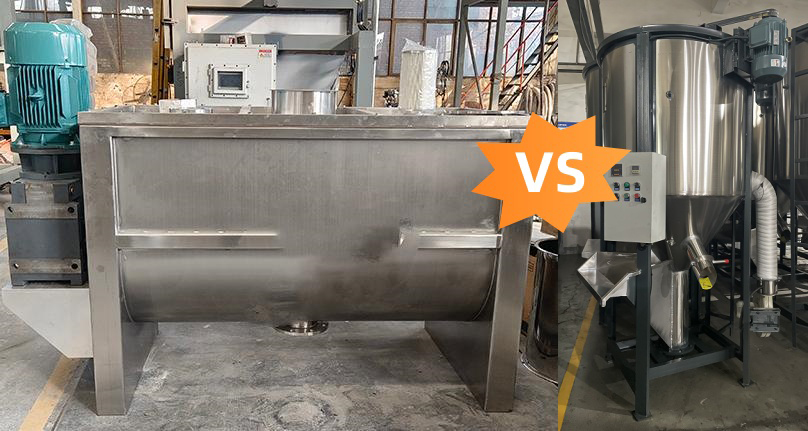

Horizontal ribbon mixers for poultry feed offer significant advantages over vertical mixers. The twin-ribbon convection mixer provides more uniform mixing, avoiding stratification that can occur with vertical mixers. The horizontal mixer has strong adaptability and can deliver large feed volumes, making it more suitable for mass production of poultry feed.

Better mixing effect: The ribbon design of the horizontal ribbon mixer can make the material form axial circulation and radial flipping in the tank, so that the feed raw materials can be fully mixed in three-dimensional space, and the mixing uniformity is higher. Vertical mixers generally use the stirring blades at the bottom to drive the material upward and then fall from the periphery to form a cycle. The uniformity of the mixing is relatively poor, especially for large-capacity mixing, which is prone to mixing dead corners.

Large processing capacity: Horizontal ribbon mixers usually have a large tank volume and can process a large amount of feed raw materials at one time, which is suitable for the production needs of large-scale poultry farms. However, due to the limitations of its structure and material lifting method, the tank volume of vertical mixers is generally small, and the single mixing volume is relatively small.

Strong adaptability to materials: Horizontal ribbon mixers have good adaptability to materials of different shapes, different particle sizes and different fluidity. Whether it is powdery, granular or paste feed raw materials, they can be fully mixed under the action of the ribbon. When a vertical mixer handles some materials with poor fluidity or high viscosity, the material may stick to the wall and be difficult to mix evenly.

Smoother discharge: The discharge port of the horizontal ribbon mixer is usually located at the bottom of the tank. The material can fall naturally under the action of gravity. With the control of the valve, the mixed feed can be discharged quickly and smoothly. When the vertical mixer discharges the material, it is necessary to lift the material from the bottom to a certain height before discharging it. For some heavier or more viscous materials, the discharge may not be smooth, and even additional auxiliary devices may be needed to help discharge the material.

High equipment stability: The horizontal ribbon mixer has a low center of gravity, good overall stability of the equipment, and is not prone to shaking or excessive vibration during the mixing process. This is not only conducive to the long-term stable operation of the equipment, reducing equipment failures and maintenance costs, but also reduces the requirements for the installation foundation. Due to its high height and relatively high center of gravity, the vertical mixer may produce large vibrations during the mixing process, requiring a more solid installation foundation and stability measures.

The Horizontal ribbon mixer for poultry feed can quickly mix various poultry feeds, including chicken/duck/goose starter feed, fattening pellet feed, laying powder feed, and nutritional supplement feed with added vitamins and minerals, adapting to the needs of different growth stages with high mixing uniformity.

Classification by form:

Powdered feed: such as corn meal, soybean meal, fish meal, stone powder, calcium hydrogen phosphate, etc.

Pelletized feed: such as crushed corn, wheat, sorghum, etc.

Crushed pellets: such as further crushing pellet feed into smaller particles.

Classification by nutritional ingredients:

Energy feed: such as corn, wheat, sorghum, etc., provide the energy required for poultry growth.

Protein feed: such as soybean meal, fish meal, meat and bone meal, etc., provide the protein required for poultry growth.

Mineral feed: such as stone powder, calcium hydrogen phosphate, salt, etc., supplement the mineral elements required for poultry growth.

Vitamin feed: such as various vitamin premixes, supplement the vitamins required for poultry growth.

Classification by feeding object:

Laying hen feed: formulated according to the different growth stages of laying hens (brooding period, rearing period, laying period) to meet the nutritional needs of laying hens.

Broker feed: formulated according to the different growth stages of broilers (brooding period, growing period, fattening period) to promote the rapid growth of broilers.

Breeder feed: formulated according to the different growth stages of breeders (brooding period, rearing period, breeding period) to ensure the health of breeders and improve the fertilization rate and hatching rate.

The price of horizontal ribbon mixer for poultry feed is affected by many factors, such as capacity, configuration, brand, etc. Generally speaking, the larger the capacity, the higher the configuration, and the higher the brand awareness, the higher the price. Our horizontal ribbon mixer for poultry feed has a price range of 2,000.00 to 2,000.00 to 9,000.00, which can meet the needs of different customers. We provide poultry feed horizontal ribbon mixers with various models and configurations. You can choose according to your actual needs and budget. If you are interested in our poultry feed horizontal ribbon mixer, please feel free to contact us for the latest quotation and detailed product information. We will wholeheartedly provide you with high-quality products and services, and work with you to create a better future!

Horizontal ribbon mixer for poultry feed plays an indispensable role in poultry feed production, ensuring the uniformity and nutritional balance of the feed through its efficient mixing structure and ease of operation. In the future, with the continuous development of technology and the growth of demand, horizontal ribbon mixers will continue to play an important role in poultry feed production, providing strong support for poultry health and production efficiency. The horizontal ribbon mixer for poultry feed we produce can also mix other materials, the materials are mixed evenly and the mixing rate reaches 100%. If you are interested in horizontal ribbon mixer, you can contact us.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.