Horizontal ribbon mixer is an efficient equipment commonly used for mixing solids and powders. It achieves fast and even mixing through its unique design and movement. In this article, we will introduce in detail the working principle, characteristics and applications of horizontal ribbon mixers in different industries.

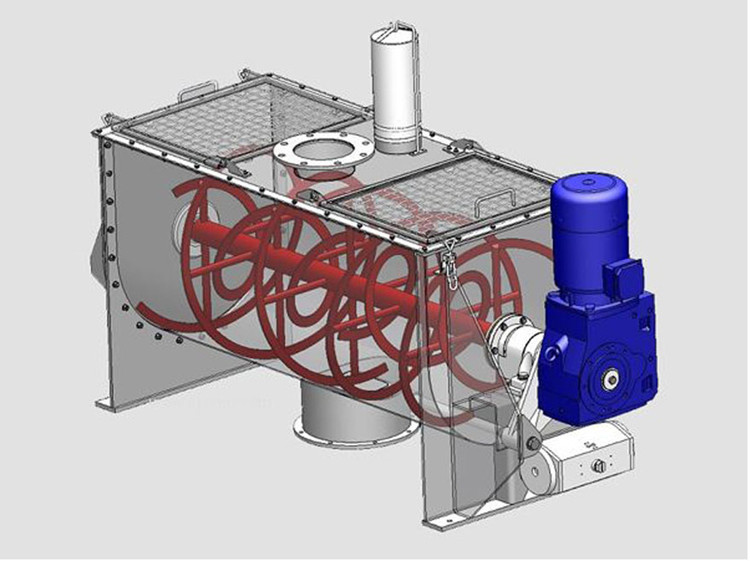

The working principle of the Horizontal Ribbon Mixer for Solids and Powders is based on the combination of a screw conveyor and a mixer. It consists of a horizontal shaft and spiral blades. When the equipment is started, the horizontal axis drives the spiral blades to rotate, causing the material to circulate in the mixer. The design of the spiral blade allows the material to be fully sheared and turned over in the mixer, thereby achieving mixing of solids and powders.

Horizontal Ribbon Mixer for Solids and Powders offers several benefits. First of all, it can evenly mix materials with different particle sizes and densities to ensure the consistency of the mixing effect. Secondly, the shearing effect during the mixing process can effectively disperse the agglomerates and improve the uniformity and stability of the mixing. In addition, the horizontal ribbon mixer has a compact structure and a small footprint, making it suitable for various production sites.

Horizontal Ribbon Mixer for Solids and Powders is used in a wide range of industries. First of all, in the food processing industry, it is used in mixed grains, powdered condiments, food additives, etc. For example, in the flour production process, a horizontal ribbon mixer can evenly mix different types of flour to ensure consistent product quality. Secondly, in the chemical industry, it can be used to mix chemicals, pigments, plastic particles, etc. In the pharmaceutical industry, horizontal ribbon mixers are used to mix pharmaceutical powders, prepare pharmaceutical granules, etc. In addition, it also plays an important role in the fields of building materials, metallurgy, environmental protection and other fields.

In order to obtain the best mixing effect, you need to pay attention to the following points when using a horizontal ribbon mixer. First, select the appropriate mixer model and configuration according to the characteristics of the material. Different materials may require different mixer parameters, such as rotation speed, mixing time, etc. Secondly, the equipment should be cleaned and maintained regularly to ensure normal operation of the equipment. In addition, operators should strictly follow operating procedures to ensure safety and stability.

The Horizontal Ribbon Mixer for Solids and Powders is a highly efficient device for mixing solids and powders. It achieves fast and even mixing through its unique design and movement. It is widely used in food processing, chemical, pharmaceutical and other industries. Through reasonable selection of equipment models, control of mixing parameters and regular maintenance, the advantages of the horizontal ribbon mixer can be fully utilized to improve production efficiency and product quality.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.