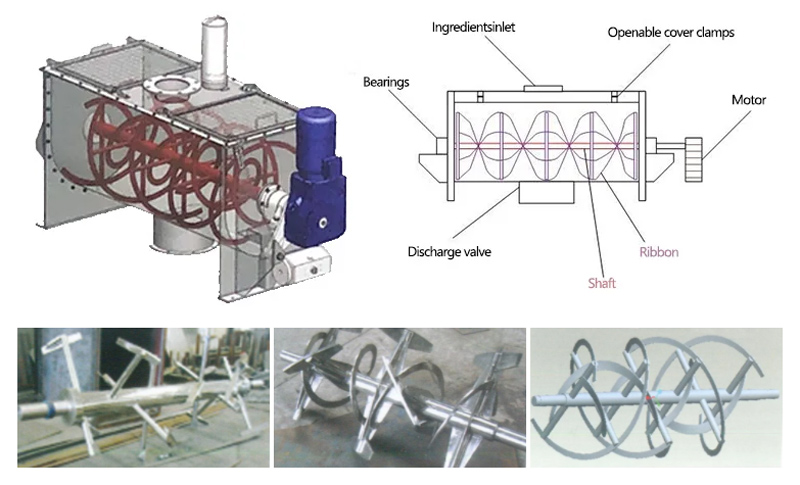

Horizontal ribbon mixer is a commonly used mixing equipment, used to uniformly mix material powders and granules of different particle sizes and compositions. It is a horizontal mixing equipment, consisting of a tank body, spiral mixing blades, transmission device and motor.

Horizontal ribbon mixers are widely used in the mixing process of feed, agriculture, chemical industry, metallurgy, building materials and other industries. In the feed and agricultural industries, it is often used to mix different types of feed ingredients. In the chemical, metallurgical and building materials industries, horizontal ribbon mixers can be used to mix powders, granular materials and additives to prepare various mixtures or finished products.

Mixing blade rotation: Start the motor and drive the mixing blade to rotate through the transmission device. The mixing blades are usually spiral-shaped and fixed on the main shaft. When the motor rotates, the mixing blades also rotate.

Mixing process: As the mixing blade rotates, the material powder begins to tumble, collide and mix inside the tank. The spiral shape and rotation direction of the mixing blade enable the material to form a continuous up and down circulation movement inside the tank.

Material flow: The shear force and centrifugal force generated by the rotation of the mixing blade push the material to flow inside the tank. The material slides down from the top of the mixing blade, and then is pushed up again by the mixing blade along the bottom of the tank, forming a circular flow.

Tumbling and collision: Materials are constantly tumbling, colliding and mixed during the circulation flow process. This tumbling and collision motion brings different particles of refractory powder into contact with each other to achieve a mixing effect.

Uniform mixing: The continuous tumbling, collision and mixing process gradually achieves uniform mixing of the material powder. Mixing time can be adjusted based on specific mixing requirements.

Uniform mixing: Through the rotation of the mixing blades and the tumbling and collision of materials, the refractory material powder is uniformly mixed to ensure the consistency of the mixture.

Efficient and energy-saving: The rotation of the mixing blades provides powerful mixing, shortening the mixing time and improving production efficiency. At the same time, the structural design and transmission device of the horizontal ribbon mixer can effectively utilize energy and save energy.

Strong adaptability: The horizontal ribbon mixer is suitable for mixing refractory powders of different particle sizes and compositions, and has good adaptability.

Easy operation: The operation of the horizontal ribbon mixer is relatively simple and easy to master and operate. At the same time, equipment maintenance and cleaning are relatively convenient.

Uniform mixing: uniformly mix material powders with different particle sizes and ingredients to ensure the consistency and stability of the mixture.

Quality control: Through monitoring and adjustment during the mixing process, the mixing quality is controlled to meet the physical and chemical performance requirements of the product.

Improve production efficiency: The efficient mixing effect of the horizontal ribbon mixer can shorten the mixing time and improve production efficiency and output.

Reduce costs: Through uniform mixing, the waste of material powder and the generation of defective products are reduced, and production costs are reduced.

In short, the horizontal ribbon mixer is an important mixing equipment. Through the rotation of the mixing blades and the tumbling and collision of the materials, the uniform mixing of the material powder is achieved. It is widely used in the mixing process of refractory materials, chemicals, metallurgy, building materials and other industries, and can improve mixing efficiency, ensure product quality, and reduce production costs.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.