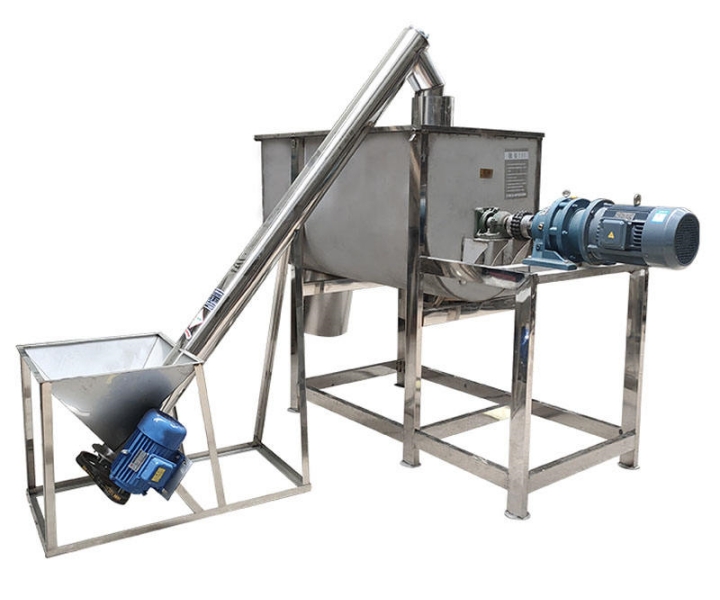

A device for efficiently and uniformly mixing feed ingredients to improve feed quality and production efficiency

![]()

![]()

Price::$1000.00-$7,900.00/Set

Consult now and enjoy a 10% discount

Mixing time: 8-20min

Capacity: Up to 1000 Liter

One-time mixing: 100-6000 (kg)

Mixing speed: 15-60r/min

Feeding method: manual feeding, automatic feeding or other methods

Discharging method: manual unloading, automatic unloading or other methods

Application: Animal husbandry, poultry breeding, feed processing industry, agriculture, animal breeding industry, poultry breeding industry, chicken farms, breeding bases.

Commitment: Free Shipping/5 Days Delivery/30-Day Returns/Support Customization

Chicken feed mixers are essential equipment for poultry farmers, ensuring that chickens receive a balanced and nutritious diet. These machines efficiently blend various ingredients, such as grains, protein sources, vitamins, and minerals, to create a complete feed that meets the specific nutritional needs of chickens at different stages of their life cycle.

Chicken feed mixer can make feed for all types of poultry and animals such as chickens, cattle, pigs, hogs, cows, horses, rabbits and other livestock, the output ranges from 100kg to 5000kg per hour, there are small and large types, small mixers range from 100kg to 800kg per hour, there are 1 ton and 2 tons options, the power is electric or diesel.

Vertical mixers and horizontal mixers are commonly used equipment for mixing chicken feed. They have their own advantages in mixing feed and are suitable for different situations.

Horizontal mixer: suitable for mixing feed raw materials with larger particles or irregular shapes, such as pellets, biscuits, block materials, etc., suitable for large-scale feed production, and high mixing efficiency.

Vertical mixer: The material is tumbled and mixed in the vertical direction, and the mixing effect is uniform. It is usually used to mix powdered or granular feed raw materials, such as powder, wheat bran, corn, soybean meal, etc. It is suitable for small and medium-sized farms to meet daily feed preparation needs.

Here are some key uses of chicken feed mixers:

Premix mixing: Mixing vitamins, minerals and other additives into feed.

Complete feed formulation: Combining grains, protein sources and other ingredients to make a balanced feed.

Medicated feed preparation: Adding drugs to feed for therapeutic purposes.

Pet food production: Mixing ingredients for various pet food formulations, including chicken pet food.

Chicken feed mixer is widely used in various scenarios, mainly including:

Poultry farms: Chicken feed mixers are commonly found in poultry farms and are used to mix different types of feed ingredients to produce nutritionally balanced feed suitable for chickens.

Farms: Farmers or breeders use chicken feed mixers to mix different types of feed ingredients to ensure that the feed contains necessary nutrients to support the growth and health of chickens.

Feed mills: Large feed mills are equipped with chicken feed mixers as part of the production line for large-scale production of various types of feed products.

Farming cooperatives: Cooperatives and breeding cooperatives also use chicken feed mixers to provide farmers with customized feed formulas to meet different breeding needs.

Farming research institutions: Feed mixers are also used in breeding research institutions to mix experimental feeds for animal nutrition research.

Individual breeders: Individual breeders or farmers may also use chicken feed mixers to mix their own chicken feed to ensure their poultry receive balanced nutrition.

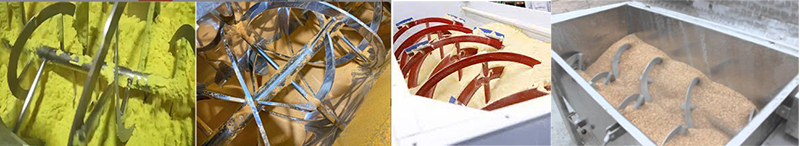

The working principle of chicken feed mixers is to fully mix various feed ingredients through a stirring device. Common stirring devices include:

Vertical mixer: uses spiral blades or paddles for stirring, suitable for mixing powdered and granular feeds.

Horizontal mixer: uses spiral ribbons or paddles for stirring, suitable for mixing powdered, granular, and block feeds.

Double-shaft paddle mixer: uses paddles installed on two parallel shafts for stirring, suitable for mixing high-viscosity and easy-to-clump feeds.

Efficient mixing

The chicken feed mixer can efficiently mix different types of feed ingredients, mix various ingredients together quickly and evenly, and improve mixing efficiency.

Good uniformity

The rotating stirring action of the mixer causes the feed ingredients to fully tumble and cross in the container, ensuring that various ingredients are fully mixed and improving the uniformity of the feed.

Easy to operate

Chicken feed mixers usually adopt automated control and are simple and convenient to operate. You only need to set parameters such as mixing time and speed to start the mixing process.

Simple structure

The structure of the chicken feed mixer is relatively simple, consisting of a mixing container, agitator and transmission device, making it easy to install and maintain.

Easy cleaning and maintenance

The design of the mixer takes into account the needs for cleaning and maintenance. Usually the surface of the container and mixer is smooth and easy to clean, reducing the risk of cross-contamination.

Strong adaptability

The chicken feed mixer can be adjusted according to different feed formulas and production needs, and is suitable for feed processing industries of different sizes and types to meet diverse mixing needs.

| Model | LHY-0.25 | LHY-0.5 | LHY-1 | LHY-1.5 | LHY-2 | LHY-3 | LHY-4 | LHY-6 | LHY-8 | LHY-10 |

| One-time mixing (kg) | 100-150 | 200-300 | 400-600 | 600-900 | 800-1000 | 1200-1800 | 1600-2400 | 2400-3600 | 3200-4800 | 4000-6000 |

| Mixing time (min) | 8-20 | 8-20 | 8-20 | 8-20 | 8-20 | 8-20 | 8-20 | 8-20 | 8-20 | 8-20 |

| Mixing speed (r/min) | 60 | 55 | 45 | 40 | 35 | 25 | 25 | 20 | 15 | 15 |

| Motor power (kw) | 3-5.5 | 4-11 | 7.5-15 | 11-18.5 | 15-22 | 18.5-30 | 22-37 | 37-55 | 37-55 | 45-75 |

| Weight (kg) | 500 | 900 | 1800 | 2500 | 3200 | 4100 | 5100 | 6300 | 7500 |

There are many types of chicken feed, and different types of feed have different requirements for mixers.

Powdered feed: such as corn meal, soybean meal, fish meal, etc., you can choose a vertical mixer or a horizontal mixer. Because powdered feed has good fluidity and is easy to mix, both vertical and horizontal mixers can meet the mixing requirements.

Granular feed: such as pellet feed, crushed feed, etc., you can choose horizontal mixers and twin-shaft paddle mixers, because there are differences in particle size of granular feed, horizontal mixers and twin-shaft paddle mixers can better ensure the mixing uniformity.

Block feed: such as silage, root and tuber feed, etc., you can choose horizontal mixers and twin-shaft paddle mixers. Because block feed requires strong shear force to break and mix, horizontal mixers and twin-shaft paddle mixers can meet the requirements.

For chicken feed mixers, some special devices can be added according to different needs and production processes to improve mixing efficiency, improve product quality, or realize automated production. The following are some common special installation designs:

Screw conveyor: Evenly convey the material into the mixer to ensure the continuity and uniformity of the mixing process.

Spray device: Spray liquid additives such as oil, vitamin liquid, etc. during the mixing process to improve the mixing effect.

Crushing device: For large pieces of material, a crushing device can be added to crush it to a suitable particle size to improve the mixing uniformity.

Dust removal device: The dust generated during the mixing process will affect the product quality and operating environment. The installation of a dust removal device can effectively solve this problem.

Trace element addition device: Used to add trace elements to ensure the balance of trace elements in the feed.

A poultry farm located in a rural area gradually expanded in scale and faced the problems of low feed preparation efficiency and poor feed uniformity. In order to improve feed quality and production efficiency, they decided to introduce a chicken feed mixer. This mixer has the characteristics of efficient mixing and good uniformity, and can mix different types of feed ingredients together quickly and evenly. After installation and debugging, the mixer is put into use, and the feed preparation work in the farm becomes efficient and simple. The automated control of the mixer makes operation easy. You only need to set parameters such as mixing time and speed to start the mixing process. At the same time, the mixer has a simple structure and is easy to clean and maintain, reducing the workload of staff. The uniformity of the feed is significantly improved, and the various ingredients in the feed are fully mixed, improving the nutritional balance of the feed. This has resulted in a significant improvement in feed quality at the farm and improved growth and health of the chickens.

Xinxiang Dahan Chicken Feed Mixer Factory is a company specializing in the production and sale of feed processing equipment, providing chicken feed mixers of various specifications and models. Our products cover small, medium and large feed mixers, with a wide range of prices, ranging from a few thousand to tens of thousands. We also provide fully automated chicken feed mixing production lines, suitable for farms and feed processing plants of all sizes. Welcome to contact us and let us provide you with high-quality feed processing equipment to help your livestock and poultry farming business.

Chicken feed mixer for small family chicken farms

A family farmer with a small scale needs a chicken feed mixer that is easy to operate, easy to clean, and can mix a variety of raw materials. A small vertical mixer is recommended for him. This mixer occupies a small area and is suitable for family farms.

Chicken feed mixer for medium-sized commercial chicken farms

A large-scale commercial chicken farm needs to produce chicken feed in large quantities. A horizontal twin-shaft paddle mixer is recommended for it. This mixer has a large processing capacity and a short mixing time, which is suitable for large-scale production; the twin-shaft paddle design has better mixing effect; the material is sturdy and durable, and has a long service life.

Chicken feed mixer for large feed processing plants

A large feed processing plant needs to produce chicken feed of various specifications. A mixer with a high degree of automation that can meet the needs of various formulations is needed.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.