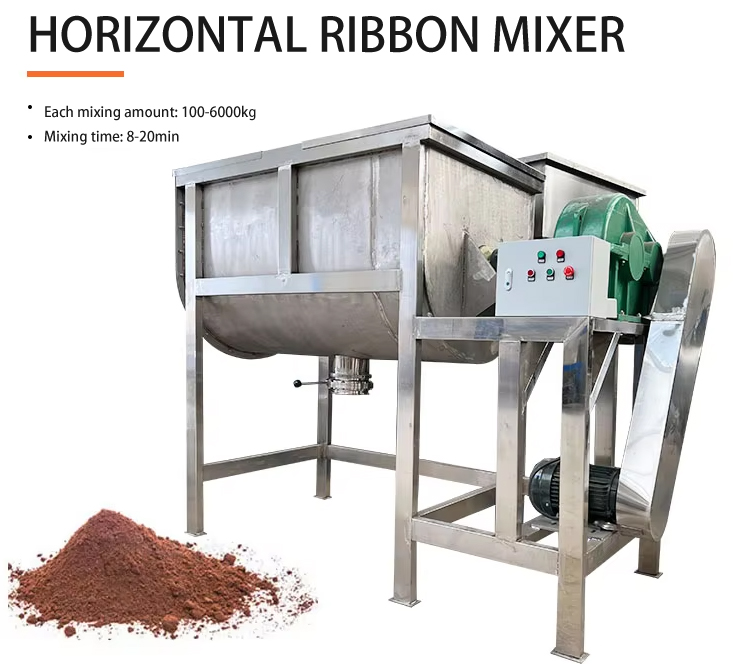

Highly efficient machines used for blending a wide range of dry and semi-moist materials. They are particularly effective for achieving thorough mixing of powders, granules, and flakes.

![]()

![]()

Price::$1000.00-$7,900.00/Set

Consult now and enjoy a 10% discount

Mixer Type: Ribbon

Mixing time: 8-20min

One-time mixing: 100-6000 (kg)

Capacity: Up to 1000 Liter

Mixing speed: 15-60r/min

Material: Q235 Carbon Steel, Stainless Steel 304 / SUS316L

Voltage: 380V/220V/450V

Application: Through the rotation of the spiral ribbon, dry powder, granules and other solid materials are evenly mixed in the U-shaped groove. It is usually used to mix dry powder, granules and other solid materials.

Horizontal ribbon mixer is also called horizontal mixer, is a common industrial mixing equipment used to mix dry powder, granules and other solid materials. The equipment usually consists of a U-shaped trough and a horizontal spiral ribbon installed in the trough. The rotational motion of the spiral ribbon causes the material to be mixed along the spiral path in the trough, thereby achieving a uniform mixing effect. This mixing method effectively maintains the particle shape and quality of the material and avoids excessive crushing and damage.

Horizontal ribbon mixer is suitable for mixing various materials such as powder and powder, powder and liquid, especially for mixing paste and viscous materials. It is mainly used for mixing corn, chili powder, condiments, feed, flour, soybean powder, feed additives and other objects.

Horizontal ribbon mixers can be divided into two types: carbon steel and stainless steel. They are common industrial mixing equipment, which differ in material, scope of application, etc.

Carbon steel horizontal ribbon mixer

Material: Carbon steel horizontal ribbon mixer is mainly made of carbon steel, with strong wear resistance and corrosion resistance.

Scope of application: This type of mixer is suitable for general industrial fields, such as chemicals, building materials, etc.

Advantages: Low cost, carbon steel material is easy to maintain and clean, low maintenance cost, and convenient maintenance.

Price: The price is relatively low, suitable for occasions with more sensitive cost requirements.

Stainless steel horizontal ribbon mixer

Material: Stainless steel horizontal ribbon mixer is made of stainless steel, with good corrosion resistance and hygiene.

Scope of application: This type of mixer is suitable for industries with high hygiene requirements such as food and medicine.

Advantages: Easy to clean, rust-proof, meets food grade requirements, and is suitable for processing food raw materials.

Price: Relatively high, but can meet high hygiene standards.

Horizontal ribbon mixers are versatile industrial mixing equipment used in various applications across different industries. Some common uses of horizontal ribbon mixers include:

Food Industry: Used for mixing dry ingredients, spices, and flavorings in food processing.

Pharmaceuticals: Suitable for blending powders and granules in the production of tablets and capsules.

Chemical Manufacturing: Employed for mixing various chemical powders and additives.

Building Materials: Commonly used for mixing cement, mortar, and other construction materials.

Plastics: Utilized for blending plastic powders and additives in the plastics industry.

Horizontal ribbon mixers and vertical mixers differ in appearance, mixing methods, and application scenarios.

Horizontal ribbon mixer: A device that uses a ribbon agitator in a horizontal U-shaped or circular cylinder to mix materials. The ribbon agitator usually consists of two layers of inner and outer spiral ribbons, and is mainly used to mix powdered and granular materials, such as dry mortar, feed, food additives, etc.

Vertical mixer: A device that uses an agitator in a vertical cylinder to mix materials. Agitators come in various forms, such as paddle type, turbine type, ribbon type, etc., which generate axial, radial, and tangential flows through rotation to achieve material mixing. Used to mix various materials, such as liquids, paste materials, powdered materials, etc., for example, in the production of coatings, cosmetics, medicines, etc.

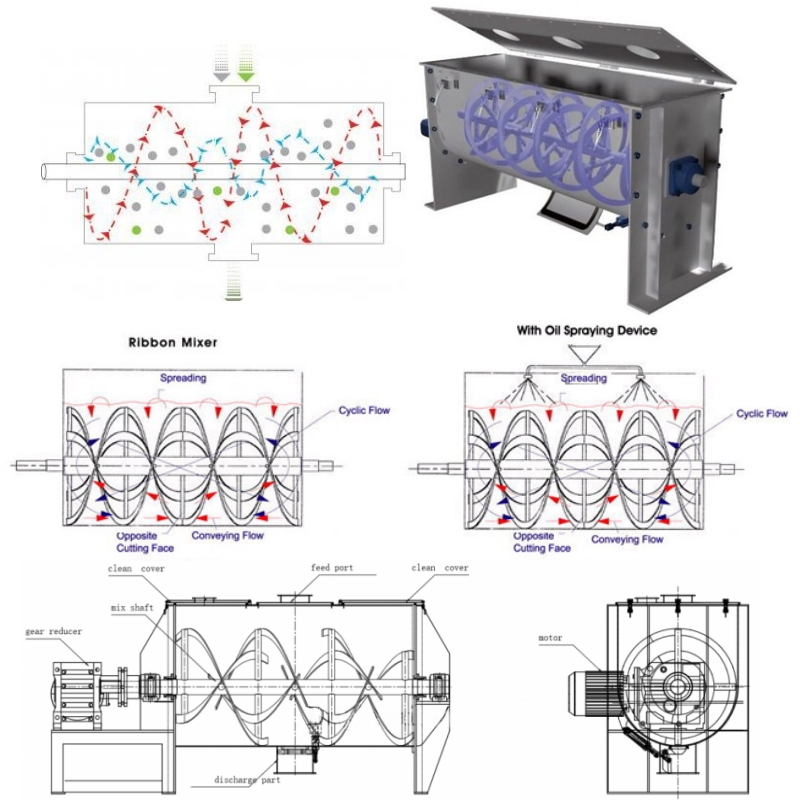

Here's a breakdown of how it works:

Ribbon Agitators: The two ribbons are mounted on parallel shafts within the trough. They are designed with a helical shape, similar to a corkscrew.

Rotation: The ribbons rotate in opposite directions at a controlled speed.

Material Movement: As the ribbons turn, they push the material back and forth through the trough. The helical shape of the ribbons creates a complex flow pattern, ensuring that the material is thoroughly mixed.

Blending Action: The combination of the ribbons' motion and the material's movement results in a cascading effect, where the material is repeatedly lifted, dropped, and folded. This action helps to break up clumps and promote even distribution of components.

Uniform mixing

The horizontal ribbon mixer can fully mix different materials and achieve uniform distribution through the rotation and shear force of the ribbon mixer. This helps improve product quality and consistency.

Efficient and fast

The structure and working principle of the horizontal ribbon mixer enable it to complete the mixing process in a short time. The design and movement mode of the ribbon mixer can quickly push and cross-flow materials to improve mixing efficiency.

Simple structure

The structure of the horizontal ribbon mixer is relatively simple, usually consisting of a mixing barrel and a ribbon mixer. This makes maintenance and cleaning of the equipment relatively easy and convenient to operate.

Strong adaptability

The horizontal ribbon mixer is suitable for mixing materials of different particle sizes, different densities and different properties. It can handle various forms of materials such as powder, granules, flakes and sticky materials.

Wide scope of application

No dead angle design: The whole machine adopts no dead angle design to ensure that the materials can be mixed evenly.

Flexible operation

Durable material: Made of high-quality stainless steel, it can extend the service life.

| Model | LHY-0.25 | LHY-0.5 | LHY-1 | LHY-1.5 | LHY-2 | LHY-3 | LHY-4 | LHY-6 | LHY-8 | LHY-10 |

| One-time mixing (kg) | 100-150 | 200-300 | 400-600 | 600-900 | 800-1000 | 1200-1800 | 1600-2400 | 2400-3600 | 3200-4800 | 4000-6000 |

| Mixing time (min) | 8-20 | 8-20 | 8-20 | 8-20 | 8-20 | 8-20 | 8-20 | 8-20 | 8-20 | 8-20 |

| Mixing speed (r/min) | 60 | 55 | 45 | 40 | 35 | 25 | 25 | 20 | 15 | 15 |

| Motor power (kw) | 3-5.5 | 4-11 | 7.5-15 | 11-18.5 | 15-22 | 18.5-30 | 22-37 | 37-55 | 37-55 | 45-75 |

| Weight (kg) | 500 | 900 | 1800 | 2500 | 3200 | 4100 | 5100 | 6300 | 7500 |

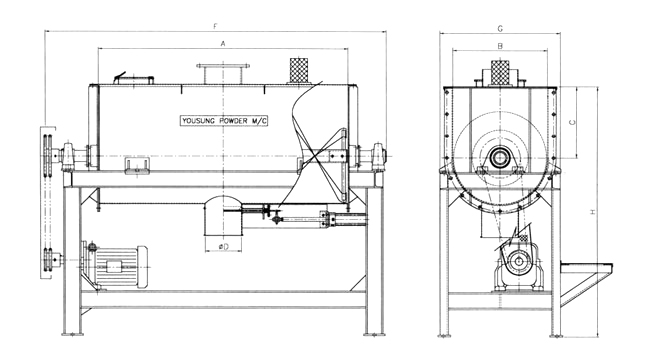

To fully understand horizontal ribbon mixers more, it is important that understand how a horizontal ribbon mixer is built and structured.

Here’s a quick table that discuss each of the parts that are common across all the different types of horizontal ribbon mixers:

| Part or Component | Function and Use |

| Ingredients Inlet (Feed Inlet) | This is the part or component where the materials are introduced inside the horizontal ribbon mixer. |

| Bearings | The bearings are the ones responsible for holding the shaft or the metal piece inside the vessel that makes the mixing possible. |

| Ribbon Blades or Agitators | These are the parts or the components that are relevant to the equation. Without them, the mixing would be different! |

| Shaft | The shaft is the part or the component that holds the agitators or the ribbon blades in place. They’re the ones connected to the bearings. |

| Discharge Port | The discharge port or the discharge valve is the component where the results or the outputs exit the machine. |

| Motor | Without a motor, the machine wouldn’t come to life. It’s the part or the component that makes the machine function and operate. |

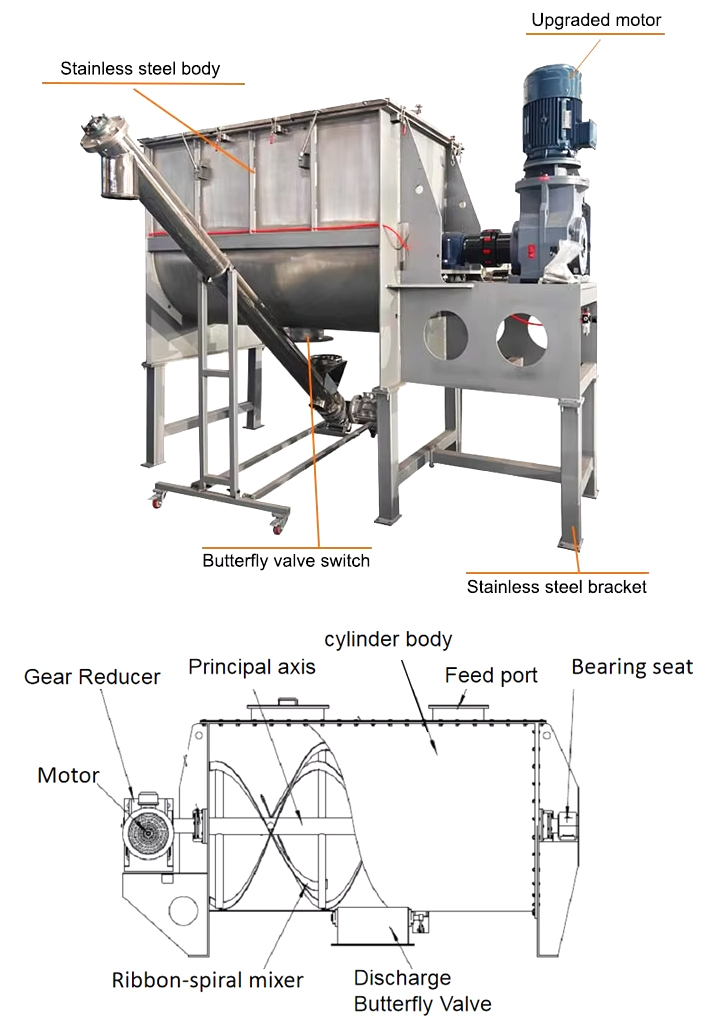

1.Flexible material selection

Material can be carbon steel, manganese steel, ss304, 316L and 321; besides, different material can also be used in combination. Surface treatment for stainless steel include sandblasting, wiredrawing, polishing, mirror polishing, all can be used in different parts of a mixer.

2.Efficient mixing device

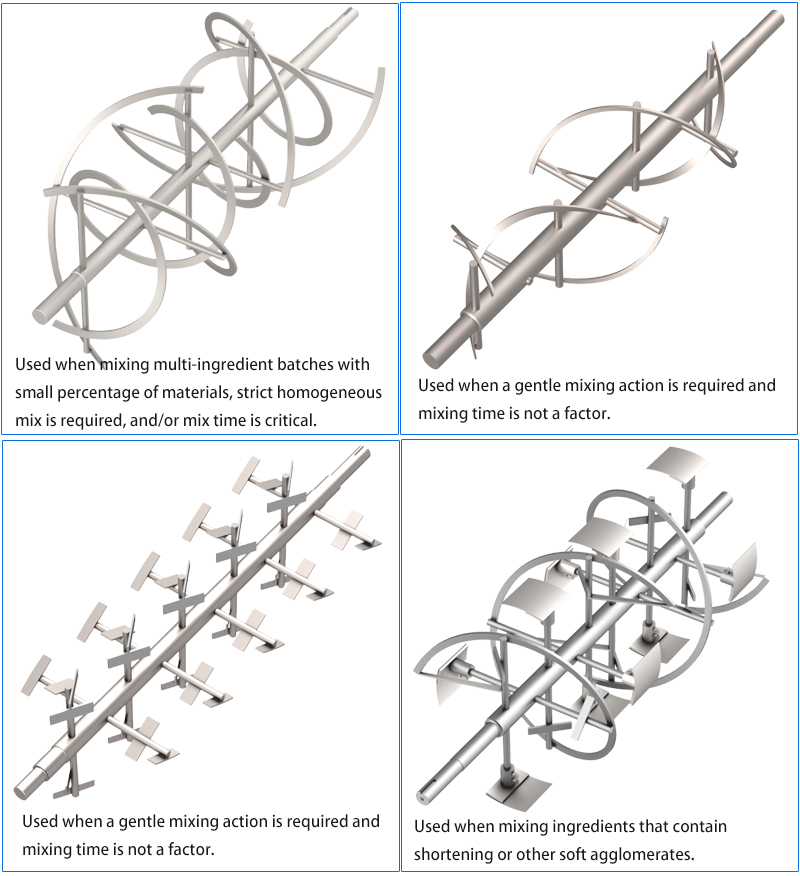

Horizontal ribbon mixer can be divided into single-ribbon and double-ribbon mixers according to its structural design and mixing mechanism.

Single-ribbon: usually consists of a single spiral ribbon fixed on the central axis, suitable for some simple mixing processes, where the mixing requirements are not particularly high.

Double-ribbon: contains two intertwined spiral ribbons fixed on the central axis to increase the mixing effect, usually used in processes that require highly uniform mixing and high mixing quality requirements, such as food, pharmaceutical and other industries.

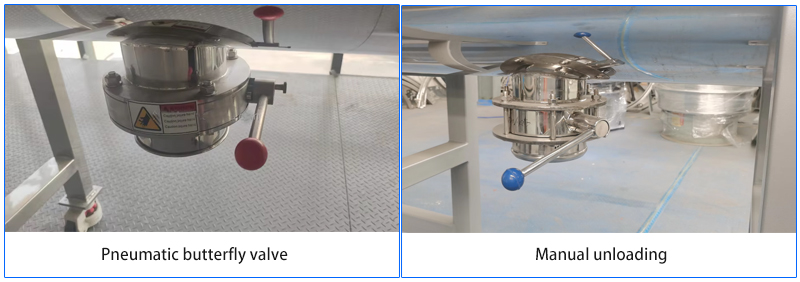

3.Discharge device

The standard horizontal screw belt mixer uses a pneumatic curved flap valve. This valve's design ensures no mixing dead angles, resulting in more uniform blends. Options include a manual discharge valve and a pneumatic butterfly valve.

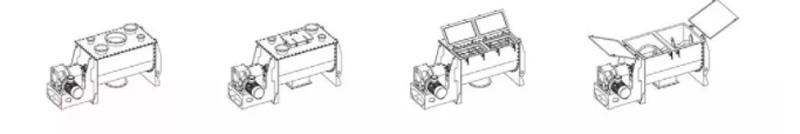

4.Various inlets

Various inlets on the top cover of the barrel can be designed according to different situations. They can be used as man hole, cleaning door, feeding hole, vent, and dust colleting hole. The top cover can be designed as fully-opened lid for easy cleaning.

A chemical company needs to uniformly mix a variety of powder raw materials during the production process to ensure product quality and consistency. They chose a horizontal ribbon mixer as the solution. The mixer is efficient and fast and can fully mix raw materials with different particle sizes and densities in a short time. By adjusting the mixer speed and mixing time, they have the flexibility to control the degree of mixing. In addition, the mixer has a simple structure and is easy to operate and clean, saving time on maintenance and cleaning. By using a horizontal ribbon mixer, the chemical company increased production efficiency, reduced product quality fluctuations, met customers' requirements for consistency and quality, and further strengthened their competitive position in the market.

| Material name | Specific gravity (g/cm³) |

Application scenarios | Mixing quantity each time (kg) |

| Flour | 0.5-0.6 | Food industry: bread and cake making | 50-500 |

| Powdered sugar | 0.8-0.9 | Food industry: candy and pastry making | 20-200 |

| Milk powder | 0.5-0.6 | Food industry: infant formula, dairy products | 10-100 |

| Salt | 2.1 | Food industry: condiment production | 50-500 |

| Compound fertilizer | 1.5-2.0 | Agriculture: fertilizer production | 1000-5000 |

| Plastic granules | 0.9-1.4 | Plastic industry: plastic product production | 500-2000 |

| Drug powder | 0.5-1.2 | Pharmaceutical industry: drug production | 10-50 |

| Dye powder | 1.0-1.5 | Chemical industry: dye production | 50-200 |

| Feed raw materials | 0.8-1.2 | Feed industry: animal feed production | 1000-5000 |

Xinxiang Dahan horizontal ribbon mixer manufacturer is a company specializing in manufacturing vibration equipment and one of the horizontal ribbon mixer manufacturers. The company has many years of industry experience and advanced production technology, and is committed to providing high-quality, reliable and efficient products. The horizontal ribbon mixer adopts high-quality materials and precision processing technology, with stable performance and long life. This product has reasonable design, easy operation and excellent mixing effect. Xinxiang Dahan horizontal ribbon mixer has won wide recognition from customers for its excellent manufacturing capabilities and good after-sales service. is one of the trustworthy horizontal ribbon mixer manufacturers.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.