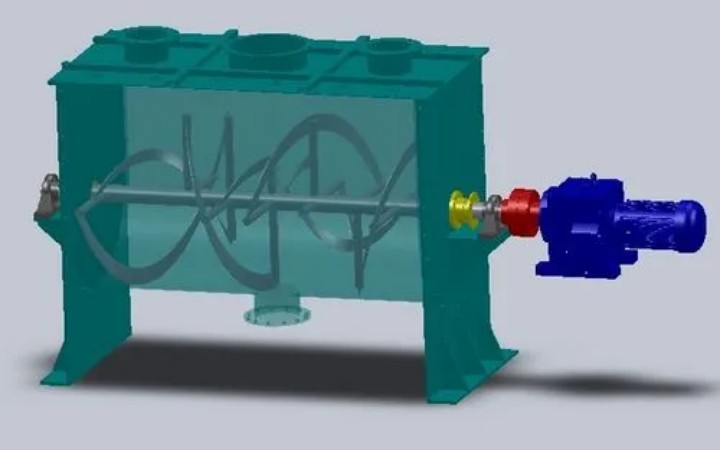

Horizontal stainless steel ribbon mixer is a common mixing equipment that adopts a horizontal structure and a spiral mixer. It can evenly mix materials with different components to achieve fast and efficient mixing effects. This equipment is widely used in food, chemical, pharmaceutical and other industries. It has the advantages of good mixing effect, convenient cleaning and corrosion resistance

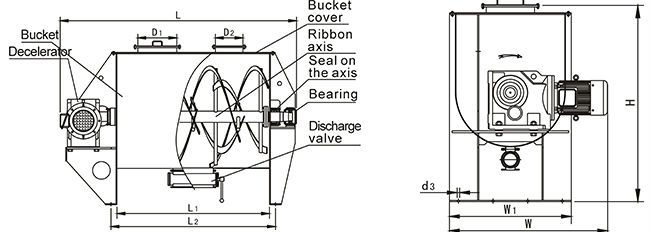

Horizontal stainless steel ribbon mixer is mainly composed of a casing, agitator, transmission device and electronic control system. The casing is usually a rectangular trough-shaped structure with one or more spiral agitators inside. The agitator is driven by a transmission device and rotates to push the materials from one end to the other to achieve the purpose of mixing.

Horizontal stainless steel ribbon mixers have a wide range of application scenarios and uses in many industries. The following are some common application scenarios and uses:

Food industry: Horizontal stainless steel ribbon mixers are often used for mixing processes in food processing, such as mixing flour, seasonings, dried fruits, nuts, etc. It ensures uniform mixing of food ingredients and improves product quality and taste.

Chemical industry: In chemical production, horizontal stainless steel ribbon mixers are widely used for mixing pigments, dyes, plastic powders, rubber and other chemical raw materials. It can fully mix chemical raw materials with different components to improve production efficiency and product quality.

Pharmaceutical industry: Horizontal stainless steel ribbon mixers play an important role in the pharmaceutical industry. It is often used in the production process of mixing pharmaceutical raw materials, pharmaceutical powders, tablets and other preparations. By mixing, the uniform distribution of the drug can be ensured and the stability and solubility of the drug can be improved.

Metallurgical industry: In the metallurgical industry, horizontal stainless steel ribbon mixers are often used for mixing metal powder, ore and other materials. It can mix different kinds of metal powders to meet the preparation needs of specific alloys.

In addition to the above industries, horizontal stainless steel ribbon mixers can also play a role in cosmetics, building materials, pesticides and other fields. Its flexibility and adjustability make it suitable for the mixing needs of a variety of materials. Whether it is solid, powder or slurry materials, the horizontal stainless steel ribbon mixer can provide efficient and uniform mixing effects to meet the production requirements of different industries.

First, put the materials to be mixed into the tank of the horizontal ribbon mixer. Then, start the mixer, which mixes the materials by rotating and turning. The spiral agitator pushes the materials from one end of the tank to the other, causing the materials to continuously roll and cross in the tank to achieve the purpose of mixing. During the mixing process, the speed and angle of the agitator can be adjusted as needed to achieve the ideal mixing effect. Finally, after the mixing is completed, open the discharge port of the tank and take out the mixed materials.

| Model | LHY-0.25 | LHY-0.5 | LHY-1 | LHY-1.5 | LHY-2 | LHY-3 | LHY-4 | LHY-6 | LHY-8 | LHY-10 |

| One-time mixing (kg) | 100-150 | 200-300 | 400-600 | 600-900 | 800-1000 | 1200-1800 | 1600-2400 | 2400-3600 | 3200-4800 | 4000-6000 |

| Mixing time (min) | 8-20 | 8-20 | 8-20 | 8-20 | 8-20 | 8-20 | 8-20 | 8-20 | 8-20 | 8-20 |

| Mixing speed (r/min) | 60 | 55 | 45 | 40 | 35 | 25 | 25 | 20 | 15 | 15 |

| Motor power (kw) | 3-5.5 | 4-11 | 7.5-15 | 11-18.5 | 15-22 | 18.5-30 | 22-37 | 37-55 | 37-55 | 45-75 |

| Weight (kg) | 500 | 900 | 1800 | 2500 | 3200 | 4100 | 5100 | 6300 | 7500 |

Uniform mixing: The horizontal ribbon mixer uses a spiral stirrer to achieve fast and uniform mixing by rotating and turning the materials. It can fully mix materials with different ingredients to ensure consistent product quality.

High efficiency and energy saving: Horizontal ribbon mixer has large mixing capacity and high mixing efficiency. It can complete the mixing process in a short time, improve production efficiency, and reduce energy consumption.

Strong adjustability: The mixing time, rotation speed, stirrer angle and other parameters of the horizontal ribbon mixer can be adjusted as needed to meet the mixing effects of different materials and process requirements.

Simple structure and easy to clean: The horizontal ribbon mixer has a relatively simple structure and is easy to clean and maintain. It is usually made of stainless steel, which is corrosion-resistant and hygienic, and meets the hygienic requirements of the food and pharmaceutical industries.

The unique ribbon mixing design and high-quality stainless steel material of the horizontal stainless steel ribbon mixer enable it to mix various types of materials.

Powdered materials: flour, starch, milk powder, seasoning powder, pigment, dye, filler, cement, lime powder, etc.

Granular materials: plastic granules, feed granules, fertilizer granules, pharmaceutical granules, salt, sugar, etc.

Flake materials: flaky additives, flaky chemicals, flaky food raw materials, etc.

Viscous materials: paste materials, sauces, adhesives, resins, colloids, etc.

Dry-wet mixed materials: dry-wet combined materials, such as wet powder, wet granules, dry-wet mixed feed, etc.

Lightweight materials: lightweight powder, fiber materials, expanded particles, etc.

Materials with high hygiene standards: pharmaceutical raw materials, food raw materials, cosmetic raw materials, etc.

Our company sells various types of horizontal stainless steel ribbon mixers, which are ideal for mixing, stirring and evenly distributing various materials in industrial production.

Small horizontal stainless steel ribbon mixer: suitable for small-scale production sites or laboratory use, with compact design and efficient stirring performance.

Medium horizontal stainless steel ribbon mixer: suitable for medium-sized production sites, capable of handling larger batches of materials and ensuring uniform mixing effect.

Large horizontal stainless steel ribbon mixer: suitable for large-scale production needs in industrial production, with high capacity and powerful stirring power, suitable for mixing various materials.

Heating horizontal stainless steel ribbon mixer: equipped with heating function, suitable for production processes that require heating treatment of materials, such as chemical industry, food processing and other fields.

Explosion-proof horizontal stainless steel ribbon mixer: with explosion-proof design, suitable for flammable and explosive places, such as chemical industry or powder processing plant.

A chemical company uses a horizontal stainless steel ribbon mixer to mix pigments. The company's pigment production line requires uniform mixing of a variety of pigment raw materials to ensure product quality. By using a horizontal stainless steel ribbon mixer, they were able to mix pigment raw materials quickly and evenly, improving production efficiency and product quality. The company is very satisfied with the performance and stability of the horizontal stainless steel ribbon mixer and plans to continue purchasing this equipment when expanding production scale in the future.

In summary, horizontal stainless steel ribbon mixers are widely used in many industries due to their advantages of uniform mixing, high efficiency and energy saving, strong adjustability and easy cleaning. Its working principle is simple and intuitive, and it can meet the mixing needs of different materials and process requirements. When selecting and using a horizontal stainless steel ribbon mixer, equipment with appropriate specifications and reliable quality should be purchased according to specific application scenarios and needs to ensure improved mixing effects and production efficiency.

The price of our horizontal stainless steel ribbon mixer varies depending on capacity, material, configuration and brand, generally $1000.00-$7,900.00/Set, and the price of customized equipment is negotiable according to demand. Factors affecting the price include material (such as 304 or 316L stainless steel), configuration (such as motor power, control system), brand and after-sales service. If you are interested in our products, please contact us directly. We provide you with a variety of specifications and customized service consultation and quotation!

Address:China,Yanjin county forest park gate to the west 1000 meters north road.