1000L stainless steel ribbon mixer is a mixing equipment with a capacity of 1000 liters, mainly composed of stainless steel spiral blades, transmission device, motor and frame. It uses the rotation and push of the spiral blades to forcefully mix the materials. This equipment has the characteristics of uniform mixing, high efficiency and energy saving, strong adjustability, and easy cleaning, and is widely used in food, chemical, pharmaceutical and other industries. The use of stainless steel materials makes the equipment have good corrosion resistance and hygiene, complying with industry hygiene standards.

The working principle of this equipment is to forcefully mix the materials through the rotation and pushing of the spiral blades. The design of the spiral blade allows the material to be fully and evenly stressed during the mixing process, thereby achieving an efficient mixing effect. At the same time, the equipment can also be heated or cooled as needed to meet the mixing requirements of different materials.

First, 1000L stainless steel ribbon mixer can achieve uniform mixing of materials and ensure the stability of product quality.

Secondly, 1000L stainless steel ribbon mixer has high mixing efficiency and energy-saving performance, which can improve production efficiency and reduce energy consumption.

In addition, the mixing time and speed of the equipment are adjustable and can be adjusted according to the requirements of different materials.

Most importantly, 1000L stainless steel ribbon mixer has a simple structure, is easy to clean and maintain, and can ensure the hygiene and safety of the production process.

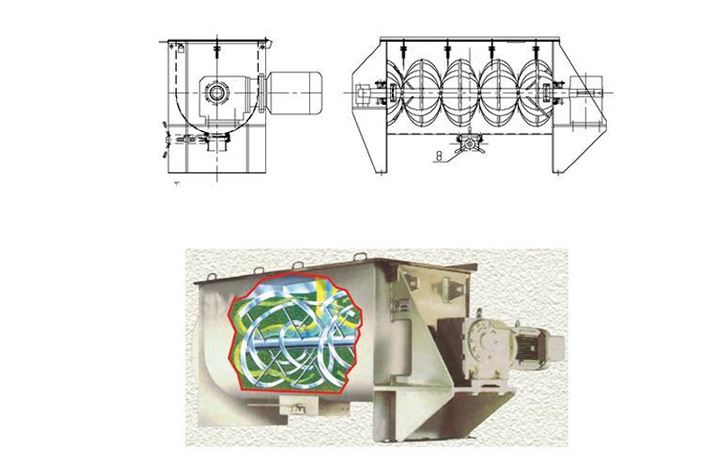

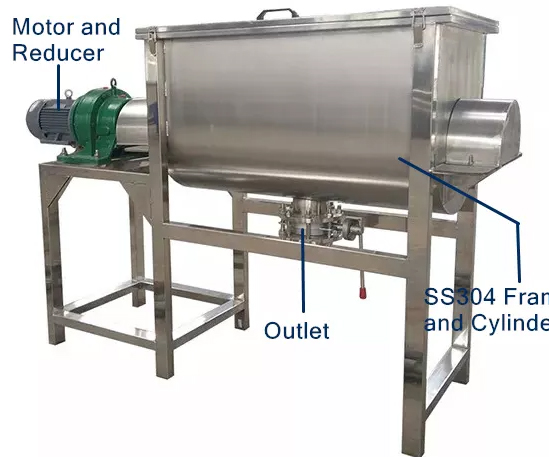

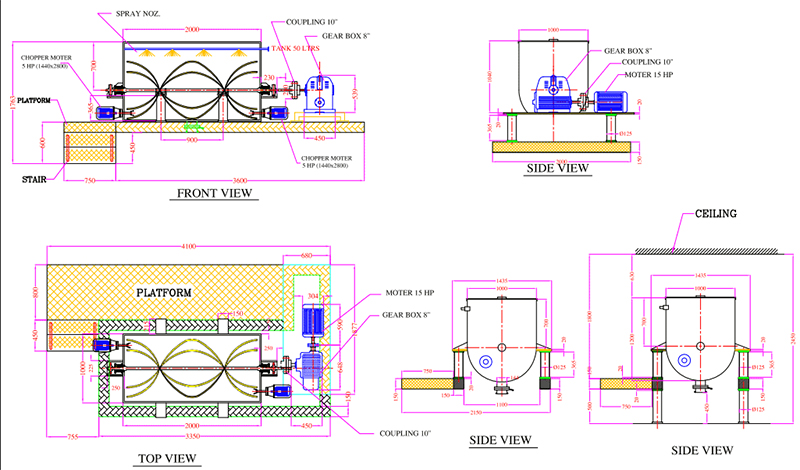

1000L stainless steel ribbon mixer is mainly composed of the following parts

Mixing barrel: Made of high-quality stainless steel material, with a capacity of 1000 liters, it is corrosion-resistant and easy to clean.

Mixing ribbon: It consists of two layers of spiral ribbons, the inner layer pushes the material outward, and the outer layer pushes the material inward, forming a convection cycle to achieve efficient mixing.

Drive system: It is composed of a motor, a reducer, etc., to provide power for the mixing ribbon.

Discharging device: Usually a pneumatic or manual butterfly valve is used to discharge the mixed material conveniently and quickly.

| Model | LHY-0.25 | LHY-0.5 | LHY-1 | LHY-1.5 | LHY-2 | LHY-3 | LHY-4 | LHY-6 | LHY-8 | LHY-10 |

| One-time mixing (kg) | 100-150 | 200-300 | 400-600 | 600-900 | 800-1000 | 1200-1800 | 1600-2400 | 2400-3600 | 3200-4800 | 4000-6000 |

| Mixing time (min) | 8-20 | 8-20 | 8-20 | 8-20 | 8-20 | 8-20 | 8-20 | 8-20 | 8-20 | 8-20 |

| Mixing speed (r/min) | 60 | 55 | 45 | 40 | 35 | 25 | 25 | 20 | 15 | 15 |

| Motor power (kw) | 3-5.5 | 4-11 | 7.5-15 | 11-18.5 | 15-22 | 18.5-30 | 22-37 | 37-55 | 37-55 | 45-75 |

| Weight (kg) | 500 | 900 | 1800 | 2500 | 3200 | 4100 | 5100 | 6300 | 7500 |

The 1000L stainless steel ribbon mixer is a multi-functional mixing equipment widely used in food, chemical, pharmaceutical, metallurgy, building materials and other industries. It plays an important role in the following application scenarios:

Food industry: Stainless steel ribbon mixers are widely used in food processing. It can be used to mix flour, seasonings, food additives, protein powder and other raw materials to ensure the uniformity and stability of the product.

Chemical industry: In chemical production, stainless steel ribbon mixers are used to mix powders, granular materials, liquids and paste materials. It is often used in the manufacture of adhesives, pigments, dyes, plastics, rubber and other products.

Pharmaceutical industry: Stainless steel ribbon mixers play an important role in the pharmaceutical process. It can be used to mix pharmaceutical raw materials such as pharmaceutical powders, preparations, tablets, and capsules to ensure uniform distribution and stability of pharmaceutical ingredients.

Metallurgical industry: In the metallurgical process, stainless steel ribbon mixers can be used to mix metal powders, ores and additives to prepare alloy materials and metallurgical products.

Building materials industry: In building materials production, stainless steel ribbon mixers can be used to mix cement, gypsum, powdery additives and other materials to prepare concrete, mortar, gypsum boards and other products.

Speed: The high mixing speed is about 5-15 minutes,

Material: The ribbon mixer can be made of SUS304 or 316 (such as SUS304 or 316).

Discharge valve: You can also choose discharge valve, butterfly valve, flap valve and gas valve discharge. Capacity range: from 50L-25000L, most of them depend on customer requirements, now the popular selling capacity is 500L, 1000L, 2000L, 5000L.

1000L stainless steel ribbon mixer is a large-capacity mixing equipment widely used in many industries. In order to ensure that you choose the equipment that suits your needs, here are some detailed purchase suggestions:

1000L capacity applicable scenario: 1000L capacity is suitable for medium-scale production needs and can meet the requirements of batch mixing. If your production scale is large or you need to mix frequently, 1000L is an ideal choice.

High-quality stainless steel: The mixing chamber, mixing shaft and blades of the mixer should be made of high-quality stainless steel (such as 304 or 316L stainless steel) to ensure corrosion resistance and hygiene standards.

Material properties: Select the appropriate motor power according to the properties of the material (such as density, viscosity, particle size, etc.). For example, mixing viscous materials requires a higher power motor.

Mixing requirements: If fast mixing or processing of high-viscosity materials is required, it is recommended to choose a higher power motor to ensure mixing efficiency.

As a professional stainless steel ribbon mixer manufacturer, we are committed to providing high-quality equipment and excellent service. We have rich experience and a professional technical team that can carry out customized design and production according to customer needs. We focus on improving product quality and performance, and ensure that each piece of equipment meets high standards through strict quality control and inspection. In addition to providing equipment, we also provide comprehensive after-sales services, including equipment installation and commissioning, operational training and technical support. We are dedicated to providing solutions and support to meet our customers' hybrid needs.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.