Utilize the rotation of the ribbon mixer to achieve uniform mixing of powders

![]()

![]()

Price::$1000.00-$7,900.00/Set

Consult now and enjoy a 10% discount

Mixing time: 8-20min

Frequency: 50HZ、60HZ

Mixing speed: 15-60r/min

Voltage: 380 V,400V, 480v

One-time mixing: 100-6000 (kg) (If it exceeds 6000kg, it can be customized according to needs)

Feeding method: manual feeding, automatic feeding or other methods

Discharging method: manual unloading, automatic unloading or other methods

Application: Widely used in food processing, pharmaceutical, chemical, agriculture, cosmetics and other industries to mix various powder raw materials such as flour, seasoning, drug powder, etc.

Commitment: Free Shipping/5 Days Delivery/30-Day Returns/Support Customization

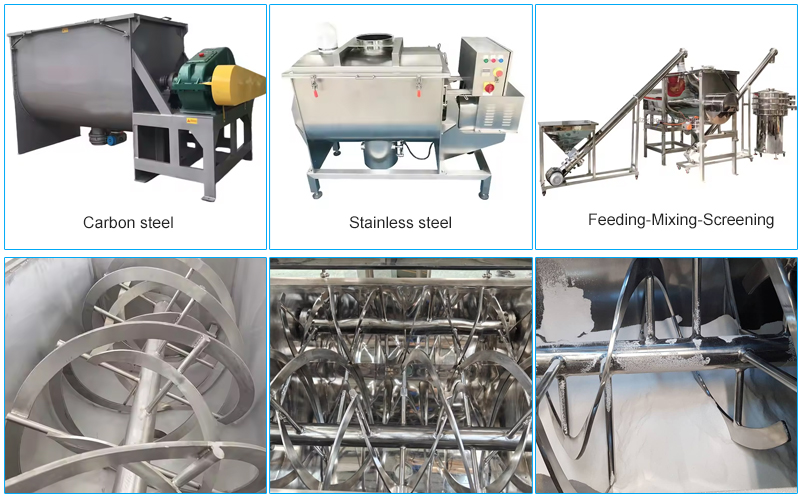

The powder ribbon mixer is a device used to mix powder materials. It is usually used in industrial production to evenly mix dry powder raw materials. The design of this mixer is based on a U-shaped horizontal trough with a spiral mixer inside. The materials are effectively mixed by rotating the mixer. The powder ribbon mixer can be customized according to your needs, including mixing time (between 3 and 15 minutes), mixing volume per time (100-6000kg, or even more), and contact material material (carbon steel, stainless steel, alloy steel, etc.). It is very suitable for mixing various powders and granular materials, such as medicines, foods, chemical raw materials, etc., and can quickly and evenly mix materials of different densities and particle sizes.

The primary function of a powder ribbon mixer is to efficiently blend and mix dry powders and granules. It's particularly effective for achieving a homogeneous mixture of materials with varying densities, particle sizes, and flow properties.

Blending: It combines different powders or granules into a uniform mixture.

Mixing: It ensures that the components of a mixture are thoroughly distributed throughout the mass.

Homogenization: It creates a consistent and uniform composition of the mixture.

Powder ribbon mixers are widely used in chemical, food, pharmaceutical, agricultural and other industries to mix various powdery materials, such as chemical raw materials, food additives, pharmaceutical raw materials, pesticide powders, etc. The powder ribbon mixer can mix powders of different densities and particle sizes efficiently and uniformly.

| Powder types | Application scenarios | Uses | Advantages | |

| Drug raw materials |  |

Pharmaceutical industry | Mix active pharmaceutical ingredients with excipients to prepare solid preparations such as tablets and capsules. | Mix evenly to ensure accurate drug dosage; less damage to heat-sensitive materials. |

| Food ingredients |  |

Food processing industry | Mix flour, sugar, milk powder, spices, etc. to make baked goods and seasonings. | Mix evenly to improve product taste and quality; can be used to produce various foods. |

| Chemical raw materials |  |

Chemical industry | Mix pigments, fillers, resins, etc. to prepare coatings, plastics, rubber, etc. | High mixing efficiency, strong adaptability, can handle a variety of chemical raw materials. |

| Cosmetic raw materials |  |

Cosmetics industry | Mix powdered cosmetic raw materials such as foundation, blush, eye shadow, etc. | Mix evenly, consistent color, improve product quality. |

| Battery materials) |  |

New energy industry | Mix battery positive and negative electrode materials to prepare lithium batteries, etc. | Mix evenly to improve battery performance and ensure battery life. |

| Ceramic raw materials |  |

Ceramic industry | Mix ceramic powders, clay, etc. to prepare ceramic products. | Mix evenly to improve the strength and density of ceramic products. |

Efficient mixing

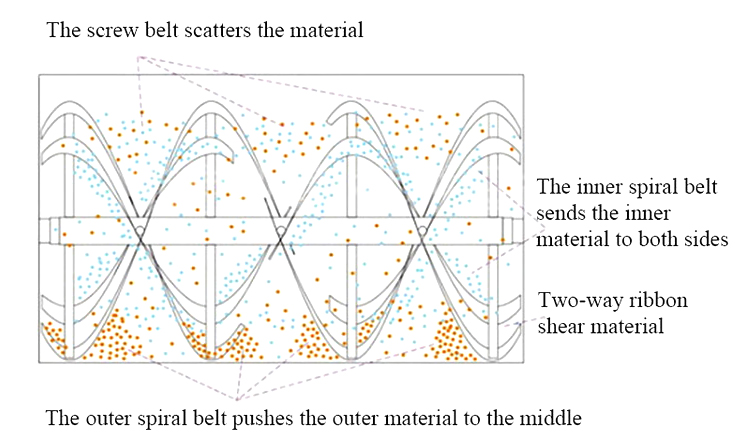

Through the rotating motion of the spiral belt, various powder raw materials are quickly and evenly mixed.

Easy to operate

simple structure, easy to operate and maintain, reducing labor costs.

Uniform mixing

Able to effectively mix powders of different densities and particle sizes to ensure consistent product quality.

Wide applicability

It can be used for powder mixing in chemical, food, pharmaceutical and other industries.

Improve production efficiency

The fast mixing process saves time and improves production efficiency.

Energy saving

It is driven by a motor, which has low energy consumption and saves energy costs.

| Model | LHY-0.25 | LHY-0.5 | LHY-1 | LHY-1.5 | LHY-2 | LHY-3 | LHY-4 | LHY-6 | LHY-8 | LHY-10 |

| One-time mixing (kg) | 100-150 | 200-300 | 400-600 | 600-900 | 800-1000 | 1200-1800 | 1600-2400 | 2400-3600 | 3200-4800 | 4000-6000 |

| Mixing time (min) | 8-20 | 8-20 | 8-20 | 8-20 | 8-20 | 8-20 | 8-20 | 8-20 | 8-20 | 8-20 |

| Mixing speed (r/min) | 60 | 55 | 45 | 40 | 35 | 25 | 25 | 20 | 15 | 15 |

| Motor power (kw) | 3-5.5 | 4-11 | 7.5-15 | 11-18.5 | 15-22 | 18.5-30 | 22-37 | 37-55 | 37-55 | 45-75 |

| Weight (kg) | 500 | 900 | 1800 | 2500 | 3200 | 4100 | 5100 | 6300 | 7500 |

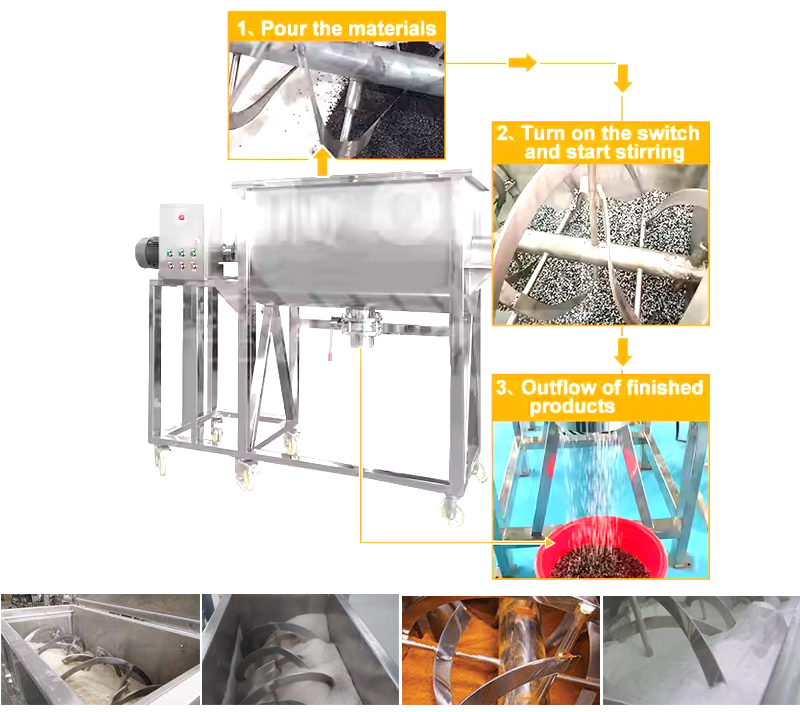

The powder ribbon mixer rotates in the cylinder to promote the powder to achieve mixing. When the equipment is started, the spiral agitator drives the powder to perform complex shearing, folding, flipping and other movements in the cylinder, so that the powder particles are constantly in contact, friction and mixing with each other, thereby achieving a uniform mixing effect.

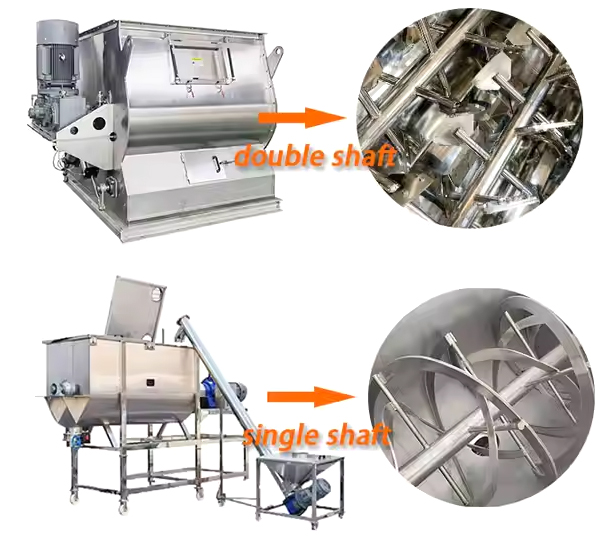

The selection of vertical and horizontal powder ribbon mixers requires comprehensive consideration of multiple factors. The following are some reference points.

Mixing effect: The ribbon of the vertical ribbon mixer is arranged vertically in the barrel. The material is mainly flipped up and down during the mixing process. For some powder materials with large specific gravity differences, uneven mixing may occur. However, the ribbon of the horizontal ribbon mixer is usually placed horizontally. The material has both axial conveying and radial flipping during mixing, which can make the material fully mixed in three dimensions in the barrel, and the mixing effect is better.

Production capacity: The filling rate of the material in the barrel of the vertical ribbon mixer is relatively low, generally around 30% - 60%, so the production capacity is relatively small. The horizontal ribbon mixer can achieve a higher material filling rate, usually up to 70% - 80%, and its mixing chamber volume is large, which can handle larger batches of materials and has a stronger production capacity.

Equipment cleaning: The internal structure of the vertical ribbon mixer is relatively simple. When cleaning, you can open the manhole or feed port on the top to clean the inner wall of the cylinder and the ribbon. The cleaning difficulty is relatively small. The internal structure of the horizontal ribbon mixer is more complicated, especially the connection between the ribbon and the shaft, which needs to be carefully cleaned to prevent material accumulation and cross contamination.

Floor space: The vertical ribbon mixer has an upright structure and a small footprint, which is suitable for use in workshops with limited space. The horizontal ribbon mixer is placed horizontally, with a larger length dimension, requiring a larger installation space, and has certain requirements for the length and height of the workshop.

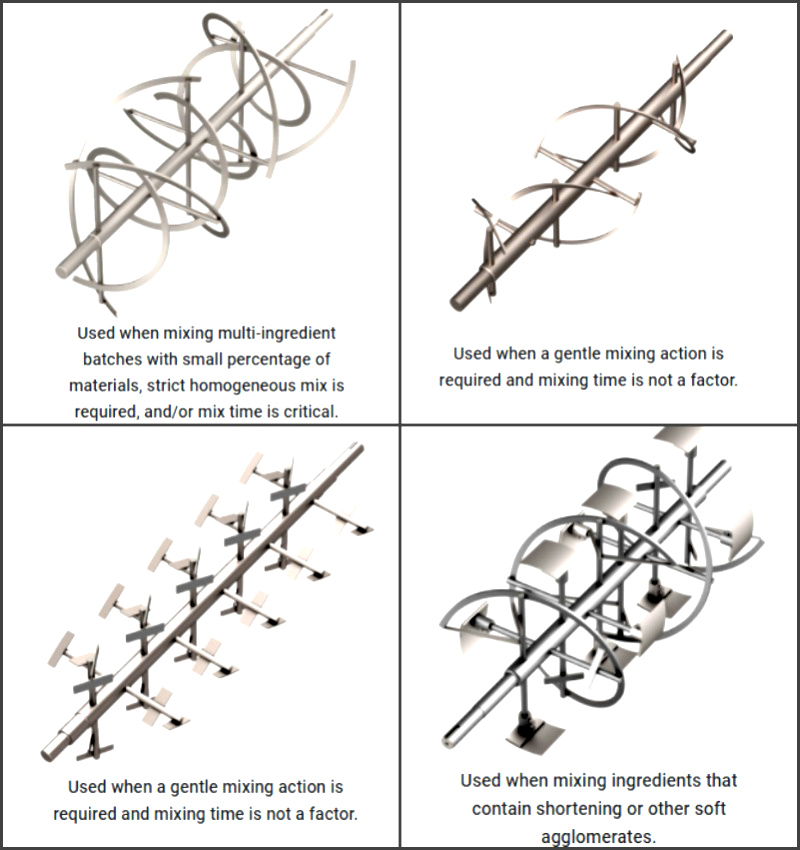

Mixing Intensity: Powder ribbon mixers generally provide a more intense mixing action due to the cascading effect of the ribbons.

Material Handling: Paddle mixers can be more aggressive in their handling of materials, which can be beneficial for breaking up clumps or agglomerates but may also damage delicate materials.

Material Properties: Ribbon mixers are often preferred for materials with varying densities and particle sizes, while paddle mixers may be more suitable for materials with similar properties.

In summary, powder ribbon mixers are generally more efficient for achieving a homogeneous mixture of dry powders and granules, especially when dealing with materials with varying properties. However, paddle mixers can be a viable option for certain applications, such as breaking up clumps or mixing materials with similar properties.

The optimal choice between a powder ribbon mixer and a powder paddle mixer depends on the specific requirements of the application, including the properties of the materials being mixed, the desired level of homogeneity, and the sensitivity of the materials to mechanical stress.

Powder ribbon mixer usually consists of a frame, motor, spiral belt, hopper, discharge port, etc.

The frame supports the entire equipment, the motor drives the spiral belt to rotate, the hopper is used to load materials, and the discharge port is used to discharge the mixed materials.

The spiral belt is the core component of the mixer, and the material is mixed through its rotation.

Some powder ribbon mixers may also include heating or cooling devices to meet specific production needs.

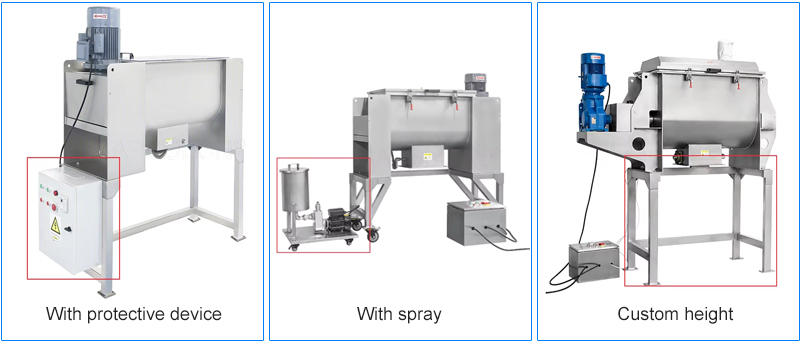

Powder ribbon mixers can be customized and adapted to suit the varying demands of individual applications.

These typically include

1. Stainless steel and carbon steel are usually used.

2. Choice of mixing trough shapes – U-shaped or circular.

3. External jackets on the mixer trough for heating or cooling the mixer contents.

4. Pressure and vacuum capable vessels for drying, heating, cooling and sterilizing applications.

5. Liquid addition facilities including pressure spraying, atomizing and gravity sparge pipe.

6. Cantilever shaft, with no non-drive end bearing or seal.

7. One-time mixing is 100-6000kg. If it exceeds 6000kg, it can be customized according to needs.

8. We offer several agitator types: Double Ribbon Multi-Pitch、Double Ribbon Standard、Paddle、Trowel.

The powder ribbon mixer can achieve a more flexible and comprehensive production process by matching with other equipment.

1. Powder ribbon mixer + screw conveyor: realize automatic feeding and reduce labor.

2. Powder ribbon mixer + vibrating screen: send the mixed materials to the grading screen for screening, and separate the materials of different particle sizes. It is suitable for occasions with strict requirements on the particle size of the mixed materials, such as ceramics, powder metallurgy and other industries.

3. Powder ribbon mixer + packaging machine: the mixed materials are directly transported to the packaging machine for packaging, realizing the integration of mixing and packaging.

4. Powder ribbon mixer + dust removal system: reduce dust pollution, protect the health of workers and environmental hygiene, and is suitable for occasions with large dust generation.

A chemical company needs to mix a variety of powder raw materials during the production process and chose our powder ribbon mixer as a solution. The mixer efficiently and uniformly mixes powders of different densities and particle sizes, improving production efficiency and product quality. Through customized design, customers' needs for mixing time, mixing quality and ease of operation are met. This powder ribbon mixer works well on the production lines of chemical companies, saving them time and costs.

| Mixed materials | Practical uses | Specific gravity (g/cm³) |

Mixing time (min) |

Mixing quantity per time (kg) |

| Flour, powdered sugar, milk powder | Food processing | 0.5 | 5 | 100 |

| Fertilizer, organic fertilizer, soil conditioner | Agricultural production | 0.8 | 10 | 200 |

| Drug excipients (lactose, starch, microcrystalline cellulose, etc.) | Pharmaceutical industry | 0.6 | 12 | 50 |

| Foundation, blush, eye shadow | Cosmetics | 0.8-1.5 | 8 | 150 |

| Spice powder (multiple) | Food seasoning | 0.4 | 6 | 80 |

| Ore powder (iron ore, copper ore, etc.) | Mining processing | 1.2 | 15 | 300 |

These cases show the application of powder ribbon mixer in different fields and its performance parameters. According to actual needs, the mixing time and mixing amount can be adjusted.

The powder ribbon mixer developed by Dahan Machinery Co., Ltd. is made of 304/316L stainless steel, with a mixing uniformity CV value of ≤3% and a residual rate of ≤0.1%. The product has passed ISO9001 and CE certification, is equipped with intelligent temperature control (±1℃) and PLC control system, and supports customized heating/vacuum/explosion-proof configuration. The main models cover a capacity of 100-5000L and are widely used in chemical, food, pharmaceutical and other industries. It has provided solutions for 500+ companies, established a 24-hour rapid response mechanism, and its products are exported to more than 30 countries and regions.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.