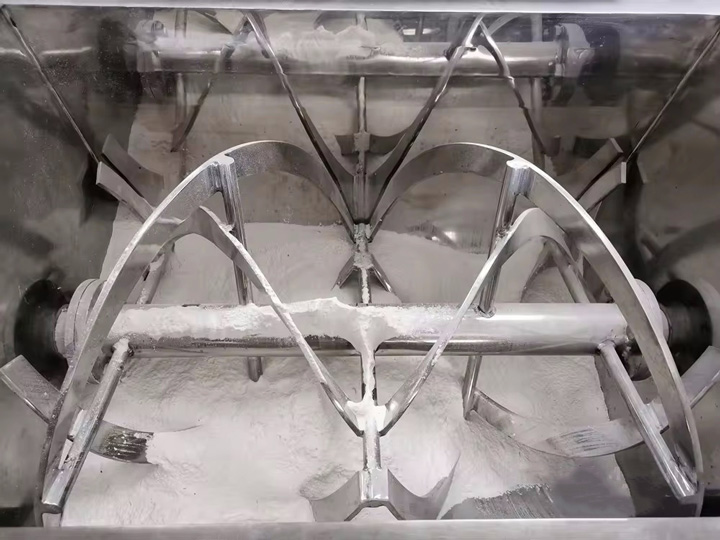

As a multifunctional industrial equipment, powder ribbon mixer has a wide range of application scenarios in many industries such as chemical, pharmaceutical, food, and building materials. Its main function is to evenly mix solid powder materials, ensure product quality, and improve production efficiency. The following will introduce the use and importance of powder ribbon mixer in detail.

In the chemical industry, powder ribbon mixers are widely used in the mixing and preparation process of various chemical raw materials. For example, in the fields of coatings, paints, rubber, plastics, etc., mixers are used to mix raw materials of different particle sizes, densities, and components to ensure stable product quality.

In the pharmaceutical industry, powder ribbon mixers are often used for the mixing and preparation of drug powders. The precise proportioning and uniform mixing of drugs are crucial to the efficacy of the drugs. The mixer can ensure that the drug ingredients are fully mixed and improve the effectiveness and stability of the drugs.

In the food industry, powder ribbon mixers are widely used for the mixing and preparation of food additives, seasonings, etc. The taste, color and mouthfeel of food are all related to the uniformity of mixing. The mixer can ensure that the food raw materials are fully mixed and improve the quality of food.

In the building materials industry, powder ribbon mixers are often used for the mixing and preparation of building materials raw materials. For example, in the production of building materials such as cement, concrete, and gypsum, the mixer is used to evenly mix various raw material powders to ensure the stable quality of building materials products.

In addition to the above industries, powder ribbon mixers also have important applications in metal powder metallurgy, agriculture, and cosmetics production. In metal powder metallurgy, mixers are used for mixing and preparing metal powders; in agriculture, mixers are used for mixing and preparing agricultural products such as feed and fertilizer; in cosmetics production, mixers are used for uniform mixing of cosmetic raw materials.

Ensure product quality: The mixer can ensure the full mixing of product raw materials, avoid agglomeration, and improve product quality stability.

Improve production efficiency: The mixer is simple to operate and can quickly and effectively mix materials evenly, improving production efficiency.

Cost saving: Efficient mixers save energy costs, reduce production costs, and improve economic benefits.

Avoid waste: The mixer can ensure that the materials are fully mixed, avoid waste, and improve production utilization.

The powder ribbon mixer provides customers with efficient and reliable mixing solutions. Our powder ribbon mixers are widely used in various industries and can be shipped to your country or region. The mixing uniformity of the powder ribbon mixer can reach 99%, and there are various models. If you want to know more about the powder ribbon mixer, please contact us immediately. Your consultation is always welcome!

Address:China,Yanjin county forest park gate to the west 1000 meters north road.