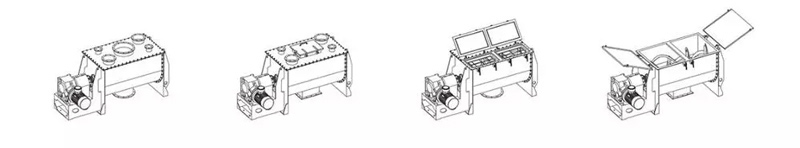

Adopting a horizontal layout, it has the advantages of small floor space, easy operation, and convenient cleaning, and can meet production processes of different scales and requirements.

![]()

![]()

Price::$1000.00-$7,900.00/Set

Consult now and enjoy a 10% discount

Mixing time: 8-20min

One-time mixing:100-6000kg (If it exceeds 6000kg, it can be customized according to needs)

Mixing speed: 15-60r/min

Power: 3.5-75kw

Weight: 100kg-7500kg

Feeding method: manual feeding, automatic feeding or other methods

Discharging method: manual unloading, automatic unloading or other methods

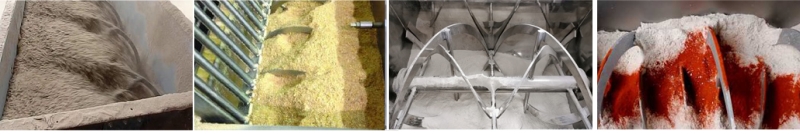

Application: Widely used in pharmaceutical, food, chemical and other industries. It can be used to mix various powder, granular or viscous materials, such as vitamins, minerals, medicinal powders, food additives, chemical raw materials, etc.

Commitment: Free Shipping/5 Days Delivery/30-Day Returns/Support Customization

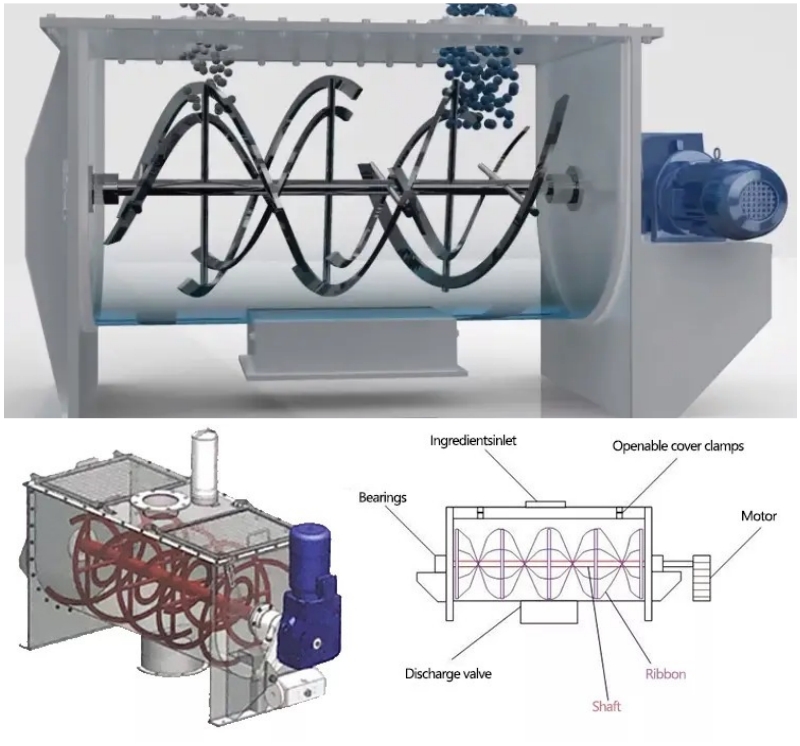

Horizontal Stirring Mixer is a common industrial mixing equipment, usually consisting of a horizontally placed stirring paddle or agitator and a container. It is mainly used to uniformly mix different materials to achieve the required mixing effect. Horizontal stirring mixers are widely used in food processing, chemical, pharmaceutical, metallurgical and other industries to prepare mixtures of various granules, powders or liquids.

The working principle of horizontal stirring mixer is to force the material to shear, fold and convectionally mix by rotating the stirring paddle or stirrer in the container. During the mixing process, the materials are continuously pushed, pulled and rotated to achieve uniform mixing. At the same time, the horizontal stirring mixer can also adjust the stirring speed and time as needed to meet the mixing requirements of different materials.

The horizontal stirring mixer has the advantages of simple structure, convenient operation and good mixing effect. It can quickly and efficiently mix materials with different ingredients to improve product quality and production efficiency. The horizontal stirring mixer has a wide range of applications and can be used to prepare various mixtures of food, chemical products, pharmaceuticals, cosmetics, etc. to meet the production needs of different industries.

Horizontal stirring mixers have a wide range of applications and uses. Here are some of the common uses:

Material mixing: horizontal stirring mixer is used to uniformly mix materials with different components. It is suitable for mixing different materials such as solid and solid, solid and liquid, liquid and liquid, such as powders, granules, pigments, additives, etc.

Stirring of reaction materials: In chemical processes, horizontal stirring mixer is used to stir and mix reaction materials to promote chemical reactions. It can improve the contact efficiency of reaction materials, speed up the reaction, and ensure the uniformity of the reaction.

Dissolution and solution preparation:Horizontal stirring mixer can be used to dissolve solid substances in liquids to prepare solutions or suspensions. It can quickly disperse and dissolve solid particles in solvents to achieve the purpose of dissolution and mixing.

Emulsification and dispersion:Horizontal stirring mixer can be used to emulsify and disperse immiscible substances in liquids. Through stirring and shearing, it can disperse oil, water or other immiscible liquids into each other and form a stable emulsion or dispersion system.

Cosmetics and Food Processing: In the cosmetic manufacturing and food processing industries, horizontal stirring mixer is used to prepare various products such as creams, lotions, jams, condiments, etc. It can evenly mix materials with different ingredients to ensure the texture and taste of the product.

Laboratory research: Horizontal stirring mixers are also widely used in laboratories for mixing small batches of samples and test materials to verify the mixing process and obtain experimental data.

The working principle of the horizontal stirring mixer is based on the effects of stirring and shearing, and the materials are mixed through the rotation of the mixer. Here's how it generally works:

Structure: horizontal stirring mixer usually consists of a stirrer and a mixing barrel. Agitators usually consist of one or more rotating blades, which may be fixed on a horizontal axis. A mixing barrel is a container used to hold materials to be mixed.

Agitator motion: TThe agitator is driven by a motor or other power source, causing it to rotate on a horizontal axis. The rotating motion of the agitator generates shear force and centrifugal force, pushing the material to the barrel wall, causing the material to tumble up and down and cross-flow in the barrel.

Mixing process: When the mixer rotates, the materials are sheared, thrown and pushed to achieve mixing of the materials. The materials continuously roll up and down and cross-flow in the mixing barrel, so that materials with different components are fully contacted and mixed. This results in fast, even mixing.

Operation control: Horizontal stirring mixers usually have an operation control system that can control the mixer speed and mixing time to meet the mixing requirements of different materials. The operator can adjust the operating parameters of the mixer as needed.

Efficient mixing

The horizontal stirring mixer can quickly and evenly mix materials with different ingredients. The rotational motion and shear force of the agitator can effectively push the material to the barrel wall, achieving cross-flow and mixing of the material, thereby improving the mixing efficiency.

Good uniformity

the horizontal stirring mixer can fully mix the materials and ensure that materials with different ingredients are evenly distributed. It can eliminate clumps and particle aggregation in the material, stabilize the quality of the mixed product, and reduce product variability.

Easy to operate

horizontal stirring mixers usually have a simple structure and operating interface, making them easy to operate and control. The operator can adjust the mixer speed and mixing time as needed to meet the mixing requirements of different materials.

Wide scope of application

horizontal stirring mixer is suitable for a variety of different materials, including solid and solid, solid and liquid, liquid and liquid, etc. It can be used in many fields such as food processing, chemical manufacturing, pharmaceutical processing, cosmetics manufacturing and laboratory research.

Controllable mixing effect

The mixing effect of the horizontal stirring mixer can be controlled by adjusting the mixer speed, mixing time and other operating parameters. This enables operators to achieve the desired mixing effect based on specific needs and material characteristics.

Stable and reliable equipment

Horizontal stirring mixers are usually made of solid structures and high-quality materials, with high durability and stability. They frequently undergo rigorous quality control and testing to ensure their reliability and performance over time.

Both ribbon mixers and paddle mixers are commonly used for mixing applications, but they have some differences in terms of their design and mixing capabilities. Here's a comparison between ribbon mixers and paddle mixers:

| Comparative Item | vertical stirring mixer | horizontal stirring mixer |

|

|

|

| structure | A vertical mixer has the agitator mounted on a vertical shaft, usually driven from above by a motor or other power source. | The agitator of a horizontal mixer is mounted on a horizontal shaft and driven from the side or below by a motor or other power source. |

| Mixing method | The agitator of a vertical mixer usually pushes the materials downward in a rotating manner, causing them to flow and mix up and down in the mixing barrel. | The agitator of the horizontal mixer pushes the material to the barrel wall through rotation and shear force to achieve cross flow and mixing of the material. |

| Application areas | Vertical mixers are often used for liquid mixing in chemical, pharmaceutical, food and other industries. They are suitable for situations where large amounts of liquid materials need to be mixed. | Horizontal mixers are widely used in the mixing of solid and solid, solid and liquid, liquid and liquid and other materials, and are suitable for chemical industry, pharmaceutical, food, cosmetics and other fields. |

| Device installation | Stand mixers usually need to be installed vertically and take up less space. | Horizontal mixers need to be installed horizontally and usually occupy a larger space. |

| Mixing effects | The vertical mixer has a good effect in liquid mixing and can quickly mix liquid materials evenly. | Horizontal mixers are more suitable for mixing solid and solid, solid and liquid materials, and can fully mix materials with different components. |

| Model | LHY-0.25 | LHY-0.5 | LHY-1 | LHY-1.5 | LHY-2 | LHY-3 | LHY-4 | LHY-6 | LHY-8 | LHY-10 |

| One-time mixing (kg) | 100-150 | 200-300 | 400-600 | 600-900 | 800-1000 | 1200-1800 | 1600-2400 | 2400-3600 | 3200-4800 | 4000-6000 |

| Mixing time (min) | 8-20 | 8-20 | 8-20 | 8-20 | 8-20 | 8-20 | 8-20 | 8-20 | 8-20 | 8-20 |

| Mixing speed (r/min) | 60 | 55 | 45 | 40 | 35 | 25 | 25 | 20 | 15 | 15 |

| Motor power (kw) | 3-5.5 | 4-11 | 7.5-15 | 11-18.5 | 15-22 | 18.5-30 | 22-37 | 37-55 | 37-55 | 45-75 |

| Weight (kg) | 500 | 900 | 1800 | 2500 | 3200 | 4100 | 5100 | 6300 | 7500 |

Flexible material selection

Material can be carbon steel, manganese steel, ss304, 316L and 321; besides, different material can also be used in combination. Surface treatment for stainless steel include sandblasting, wiredrawing, polishing, mirror polishing.

The driven unit

Options for motor: general motors, explosion-proof motors, variable frequency motor, high efficiency and energy saving motor. Commonly used reducers: R-series, K-series, and F-series gear box; cycloidal reducer, universal gear reducer, planetary gear reducer.

High efficiency mixing unit

Different main shaft agitators can be equipped according to the properties of raw materials.

The main shaft agitator could be: inner and outer ribbon, paddle and ribbon, disconnected ribbon, and shaver-shaped agitator.

Excellent discharging unit

The drive types of valve are Manual, pneumatic, and electric.

Valves for consideration: powder spherical valve, cylinder valve, plum-blossom dislocation valve, butterfly valve, rotary valve etc.

Various inlets

Various inlets on the top cover of the barrel can be designed according to different situations.

They can be used as man hole, cleaning door, feeding hole, vent, and dust collecting hole. The top cover can be designed as fully-opened lid for easy cleaning.

A food processing company uses horizontal stirring mixer to improve product quality and production efficiency. The food products they produce require a uniform blend of multiple ingredients to ensure consistent taste and quality. By introducing the horizontal stirring mixer, they are able to mix different ingredients quickly and efficiently, greatly reducing mixing time and the need for manual operations. This not only improves product uniformity and quality stability, but also improves production efficiency, allowing the company to meet market demand faster. The horizontal stirring mixer has a simple structure, easy operation and excellent mixing effect, which has brought significant improvements and efficiency gains to the company's food processing process.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.