The horizontal gravityless shaft paddle mixer is a highly efficient mixing equipment designed with a horizontal structure. It consists of a spindle, a paddle, a trough, a motor, etc., and has excellent mixing effects and easy operation. The equipment can be customized for different process requirements to meet customers' specific mixing needs. This equipment has become one of the preferred equipment in many industries due to its efficient and uniform mixing effect.

1. Chemical industry: used for mixing and stirring coatings, pigments, dyes, adhesives, etc.

2. Pharmaceutical industry: used for mixing, uniform dispersion and dissolution of drugs.

3. Food industry: used for mixing and stirring food additives, condiments, jams, etc.

4. Detergent industry: used for mixing and even dispersion of washing powder, dishwashing liquid, etc.

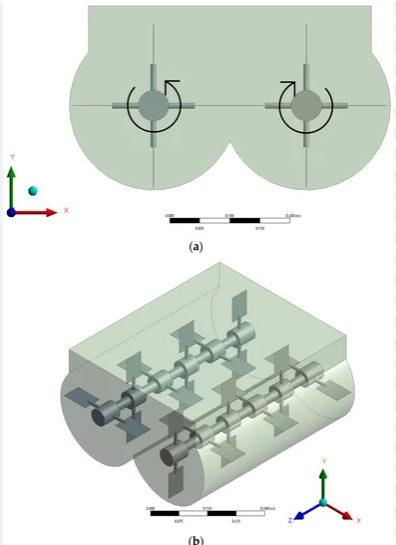

1. High mixing efficiency: Using specially designed double-shaft paddles, it can mix materials quickly and evenly, improving production efficiency.

2. Good uniformity: The gravityless design avoids the gravity settlement of materials and ensures the uniformity of the mixed materials.

3. Easy to operate: The equipment adopts an advanced automated control system, which is easy to operate and can be adjusted and monitored according to process requirements.

4. Durable and reliable: Using high-quality manufacturing materials and sophisticated workmanship to ensure the durability and stability of the equipment.

The working principle of the horizontal gravityless shaft paddle mixer is to drive the paddles to rotate through the main shaft to shear, fold and mix the materials to achieve the mixing effect. Due to the horizontal design and gravityless nature of the equipment, materials can be fully contacted and exchanged during the mixing process to achieve uniform mixing.

A chemical company used a horizontal gravityless shaft paddle mixer in the production of pigments and achieved remarkable results. This equipment can quickly mix pigments with different components to ensure the uniformity and quality stability of the pigments. Customer feedback shows that after using this equipment, production efficiency has increased by 30%, product quality has been significantly improved, and operation has become more convenient and reliable.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.