In modern animal husbandry, high-quality feed is one of the key factors to ensure animal health and production efficiency. To meet the growing demand for feed, the feed processing industry requires high-performance equipment to achieve fast and uniform feed mixing. As an excellent choice, high-Performance feed ribbon mixer has become the preferred equipment for feed processing plants due to its excellent mixing effect and efficient working ability.

High-Performance feed ribbon mixer ensures uniform distribution of feed ingredients through an efficient mixing process, improving the efficiency and quality of feed processing. Its precise control system, durable and reliable structure and multi-functional application range make it widely used in other industrial fields.

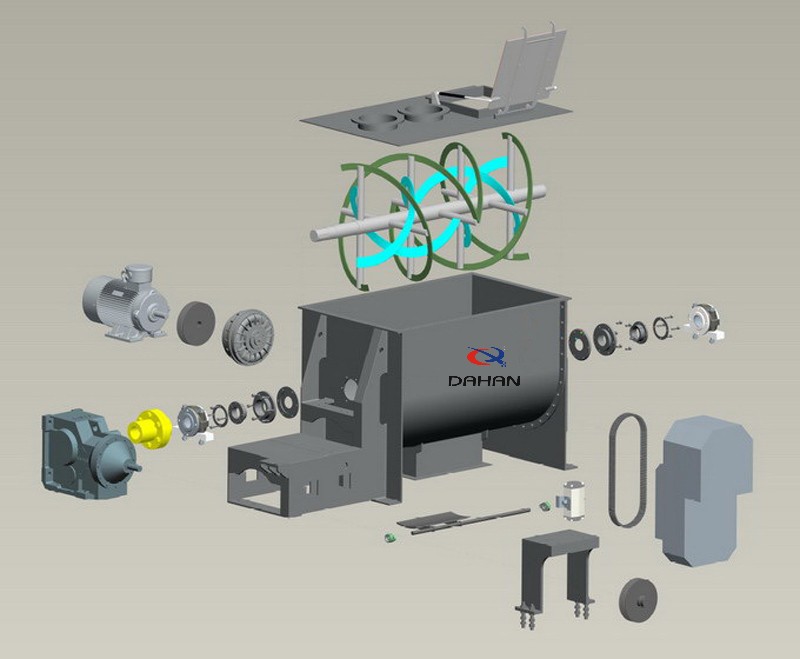

The High-Performance feed ribbon mixer uses the rotation and pushing action of spiral blades to mix feed ingredients of different ingredients. When the machine is started, the spiral blades start to rotate, pushing the material from the feed port into the inside of the mixer casing. The special design of the spiral blade allows the material to be continuously turned and stirred in the casing, thereby achieving a fast and uniform mixing effect. Finally, the mixed feed is discharged through the discharge port and is ready to enter the next production process.

Efficient mixing capacity: Using advanced design and technology, the special shape and layout of the spiral blades enable the materials to be fully turned and crossed during the mixing process to achieve the best mixing effect.

Large batch processing capacity: It has a large capacity casing and can handle large batches of feed ingredients.

Precise control system: High-Performance feed ribbon mixer is equipped with an advanced control system that can accurately control parameters such as mixing time, mixing speed and mixing ratio.

Durable and reliable structure: High-Performance feed ribbon mixer is made of high-strength materials with good wear resistance and corrosion resistance. At the same time, its structural design is reasonable, and the transmission device and sealing device are carefully designed and optimized.

Versatile application range: High-Performance feed ribbon mixer can handle a variety of powdery, granular and flake materials to meet the mixing needs of different industries.

Feed processing plant: High-Performance feed ribbon mixer is one of the important equipment in the feed processing plant. It can evenly mix different types and proportions of feed ingredients to ensure nutritional balance and stable quality of the feed.

Farm: Farms often need to prepare their own feed to meet the nutritional needs of animals at different stages. High-Performance feed ribbon mixer can mix various feed ingredients to produce nutritionally balanced feed suitable for farmed animals.

Feed additive manufacturing enterprises: Feed additives are an important part of improving feed quality and animal health. High-Performance feed ribbon mixer can mix different types of feed additives to ensure uniform distribution of additives and improve product quality.

Material selection: When using high-Performance feed ribbon mixer for mixing, suitable feed ingredients should be selected. The differences in particle size, humidity and composition of the materials should not be too large to ensure the uniformity and stability of the mixing effect.

Mixing time: Mixing time is an important factor affecting the mixing effect. The mixing time should be set reasonably according to the characteristics and mixing requirements of the specific materials to ensure sufficient mixing, but to avoid the loss of energy consumption and mixing quality caused by excessive mixing.

Mixing ratio: Mixing ratio refers to the ratio of different feed ingredients during the mixing process. The mixing ratio should be set reasonably according to the feed formula and the nutritional needs of the animals to ensure the uniformity and nutritional balance of the feed.

Cleaning and Maintenance: Regular cleaning and maintenance of the high-Performance feed ribbon mixer is key to ensuring its normal operation and extending its service life. Dust and impurities inside and outside the machine should be cleaned regularly, and worn parts should be inspected and replaced.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.