Fertilizer Ribbon Mixer price will be affected by multiple factors, including equipment specifications, material selection, production capacity, brand and market supply and demand. The factors related to the price of fertilizer ribbon mixer will be introduced in detail below.

First of all, equipment specifications are one of the main factors that affect price. The specifications of the fertilizer ribbon mixer include mixing barrel capacity, motor power, mixing speed, etc. Generally speaking, equipment with larger capacity, higher power, and faster mixing speed will have a relatively higher price.

Secondly, material selection will also have an impact on price. Common fertilizer ribbon mixer materials include stainless steel and carbon steel. Stainless steel has good corrosion resistance and hygienic performance and is suitable for industries with high requirements. Therefore, the price of stainless steel fertilizer ribbon mixer is relatively high. Carbon steel materials are more common and economical, so the price of carbon steel fertilizer ribbon mixers is relatively low.

In addition, production capacity is also one of the factors affecting prices. Fertilizer ribbon mixers of different specifications have different production capacities. The price of equipment with greater production capacity is usually relatively higher. For example, small laboratory-grade mixers are less expensive, while larger industrial-grade mixers are more expensive.

Finally, brand and market supply and demand will also have an impact on the price of fertilizer ribbon mixers. Equipment from well-known brands usually costs more because they have better quality and reliable after-sales service. Market supply and demand will also have a certain impact on prices. Prices may fall when there is excess supply, and prices may rise when supply is tight.

|

Horizontal fertilizer ribbon mixer price |

Stainless steel |

5,000-20,000 yuan |

Stainless steel horizontal fertilizer ribbon mixer has excellent corrosion resistance and hygienic performance, and is suitable for preventing corrosion when materials come into contact with equipment and meeting hygienic requirements in production environments. The 10 materials it can mix include organic fertilizers, inorganic fertilizers, compound fertilizers, animal feed, powdered pesticides, food additives, chemical raw materials, plastic particles, ore powder, and plant ash. |

|

Carbon steel |

3,000-10,000yuan |

Carbon steel horizontal fertilizer ribbon mixer is suitable for general mixing needs and is widely used in chemical fertilizer, pesticide, plastic, chemical and other industries. It can be used to mix various fertilizers and granular materials, such as organic fertilizers, inorganic fertilizers, compound fertilizers, etc. Mixers made of carbon steel are relatively low-priced, economical, and suitable for scenarios with limited budgets. |

|

|

Vertical fertilizer ribbon mixer price |

5,000-20,000 yuan |

Vertical fertilizer ribbon mixer is suitable for small batch mixing and limited space scenarios. It can be used to mix various fertilizers and granular materials, such as organic fertilizers, inorganic fertilizers, compound fertilizers, etc. The vertical design allows it to occupy a smaller area, making it suitable for factories or workshops with limited space. It is usually used in scenarios such as laboratories, R&D centers, or small-scale production lines. |

|

|

Material |

|

Stainless Steel Fertilizer Ribbon Mixer Generally speaking, the price of stainless steel fertilizer ribbon mixer will be relatively high, because stainless steel has the characteristics of corrosion resistance and wear resistance, is suitable for places with high hygiene requirements, and has a large blanking space. |

|

Carbon Steel Fertilizer Ribbon Mixer The price of carbon steel fertilizer ribbon mixer is relatively low, and in general agricultural and industrial applications, carbon steel fertilizer ribbon mixer may be more common and economical. |

|

|

Type |

|

Horizontal fertilizer ribbon mixer Horizontal fertilizer ribbon mixing structure is simple, and reduces capital investment during use, so it is often used. Horizontal fertilizer ribbon mixer is suitable for mixing larger batches of fertilizers and is commonly used in agriculture, chemical industry and other fields. |

|

Vertical fertilizer ribbon mixer Compared with horizontal mixers, vertical mixers have a more compact structure and occupy a smaller area. The vertical fertilizer ribbon mixer is suitable for mixing smaller batches of fertilizer and is commonly used in laboratories, small production lines and other scenarios. |

|

|

Product matching |

|

Fertilizer ribbon mixer with belt conveyor On the production line, the fertilizer ribbon mixer can be used with a belt conveyor to transport raw materials to the feed port of the fertilizer ribbon mixer through the belt conveyor to realize automated raw material supply. At the same time, the mixed fertilizer can also be transported through a belt conveyor and connected to the next processing link, such as packaging or storage. |

|

Fertilizer ribbon mixer with screening machine On the production line, the fertilizer ribbon mixer can be used with a screening machine. The mixed fertilizer can be graded through the screening machine to obtain fertilizer particles that meet the requirements. This helps improve the quality and uniformity of the fertilizer. The screening machine can select different mesh sizes as needed to meet different particle size requirements. |

|

|

Fertilizer ribbon mixer with elevator On the production line, the fertilizer ribbon mixer can be used with an elevator. The elevator can vertically lift the mixed fertilizer to the inlet of the storage or packaging equipment. The elevator can choose different heights and speeds as needed to adapt to the requirements of the production line. |

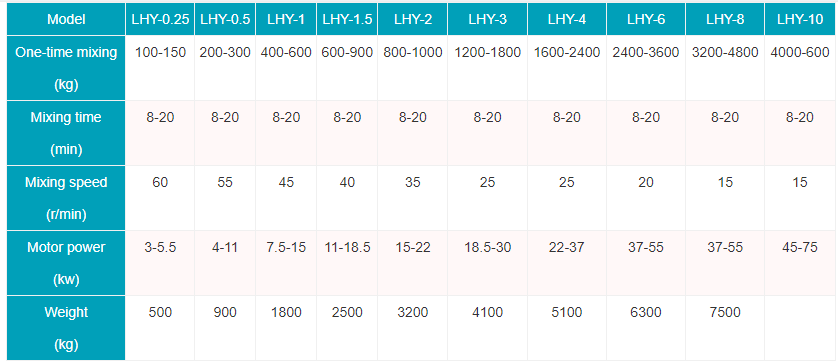

If you have a brief understanding of the price, here is a detailed model parameter list.

Efficient mixing: The equipment can quickly and evenly mix fertilizer raw materials through screw conveying and rotating mixing device blades to ensure good mixing effects.

Simple operation: The equipment has a simple structure and is easy to operate. Just put the fertilizer raw materials into the feed port to start the mixing process.

Uniform distribution: The rotating blades of the mixing device cause the fertilizer raw materials to continuously roll and cross within the device, thereby achieving even distribution of fertilizer.

Improve fertilizer quality: During the mixing process, the equipment can fully mix different types and proportions of fertilizer raw materials to provide comprehensive nutrition and improve the quality of fertilizer.

Reduce costs: By mixing different raw materials, fertilizer costs can be effectively reduced and the nutrient needs of different crops can be met.

A farm fertilization company uses a fertilizer ribbon mixer to meet the nutrient needs of different crops. They have multiple farmlands, each with different requirements for fertilizer proportions and ingredients. By using fertilizer ribbon mixers, they are able to mix different types and proportions of fertilizer raw materials to prepare nutritional fertilizers that meet the needs of each farmland. This not only improves crop growth, but also reduces fertilizer costs and increases farmland yields and economic benefits.

Fertilizer ribbon mixers have a wide range of application scenarios in the agricultural field. It is mainly used to mix different types of fertilizer raw materials to obtain a uniform fertilizer formula. The following are some application scenarios of fertilizer ribbon mixers:

Farmland fertilization: The fertilizer ribbon mixer can mix different types of fertilizer raw materials (such as nitrogen, phosphorus, potassium fertilizer, etc.) to make compound fertilizer to meet the nutritional needs of farmland.

Vegetable cultivation: In vegetable cultivation, different types of fertilizers need to be mixed in certain proportions to provide proper nutrient supply. The fertilizer ribbon mixer can effectively mix fertilizer raw materials together to provide a balanced nutrient formula.

Orchard management: Fruit trees have different nutrient needs. The fertilizer ribbon mixer can accurately mix different types of fertilizers according to the needs of fruit trees to provide appropriate nutrient supply.

Flower care: Flowers also have different nutrient needs. The fertilizer ribbon mixer can mix different types of fertilizers according to the needs of flowers to provide appropriate nutritional support and promote the healthy growth of flowers.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.