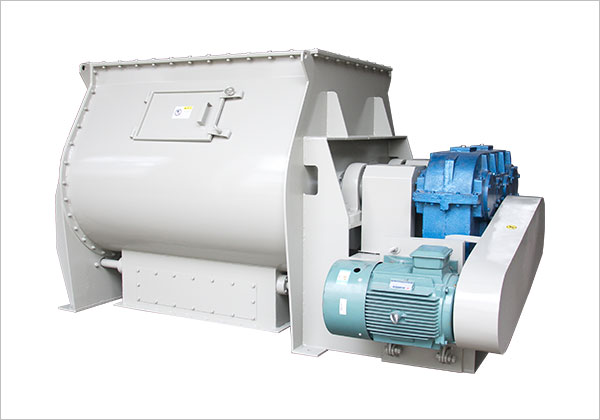

The twin shaft paddle mixer is a commonly used mixing equipment, suitable for mixing granules, powders and viscous materials. The twin shaft paddle mixer works by using the stirring action of two rotating main shafts and paddles to achieve uniform mixing of materials. The shape and arrangement of the paddles can be designed according to different mixing requirements to achieve better mixing effects. This kind of mixer has a simple structure, good mixing effect, and is suitable for a variety of materials. Therefore, it is widely used in chemical, pharmaceutical, food and other industries.

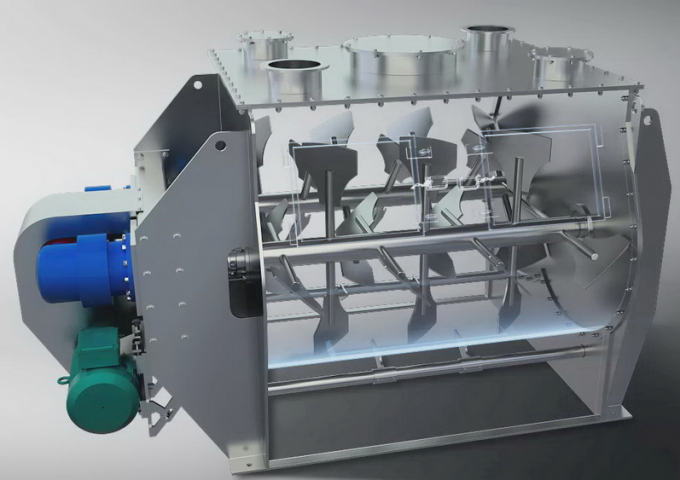

The twin shaft paddle mixer consists of two parallel main shafts, each of which is equipped with symmetrically arranged paddles. The paddle is usually blade-shaped and can be straight, curved or spiral, and is designed according to the mixing requirements. The container of the mixer is usually a U-shaped trough, with a discharge port at the bottom of the container.

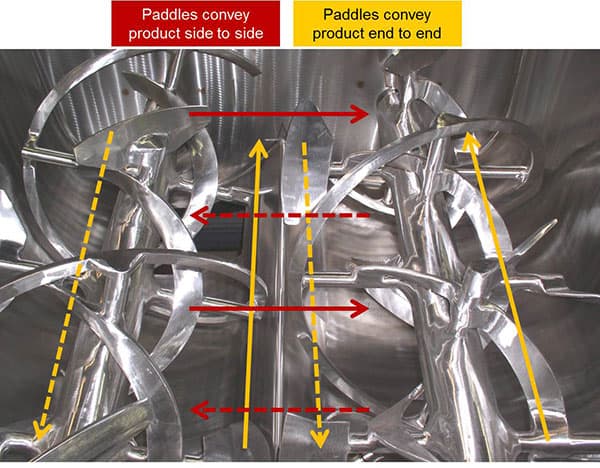

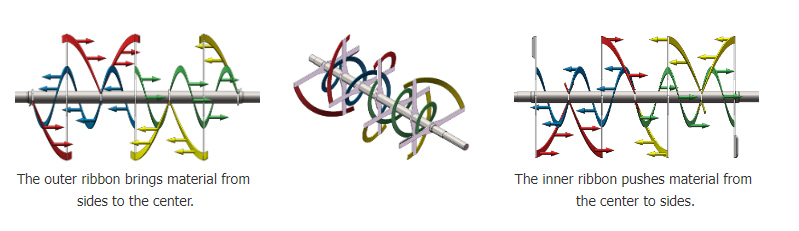

When the mixer is started, the two main shafts start to rotate and the paddles perform stirring motion in the container. The rotation direction of the paddles is opposite, causing the materials to continuously flip, fold and cross-move inside the container. At the same time, due to the shape and arrangement of the blades, the material will also flow and shear in the axial and radial directions, thereby achieving more uniform mixing.

The material is put into the container of the mixer from the top and gradually flows downward with the stirring motion of the paddle. The stirring effect of the paddle causes mutual collision and friction between materials, thereby achieving mixing between particles and between particles and powder. During the mixing process, the material continues to rise along the wall of the container, and then is brought back to the mixing area by the paddle again, where it is circulated and mixed until the required mixing effect is achieved.

When the mixing is completed, open the discharge port and the material will be discharged from the bottom. Due to the stirring effect of the mixer, the residence time of the material in the container is relatively short, which can effectively avoid the agglomeration and accumulation of materials and ensure the quality of the mixed materials.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.