Dry powder mixer is a device used to mix and evenly distribute dry powder or granular materials. Its working principle involves a variety of mechanical and physical processes. The working principle of the dry powder mixer will be introduced in detail below.

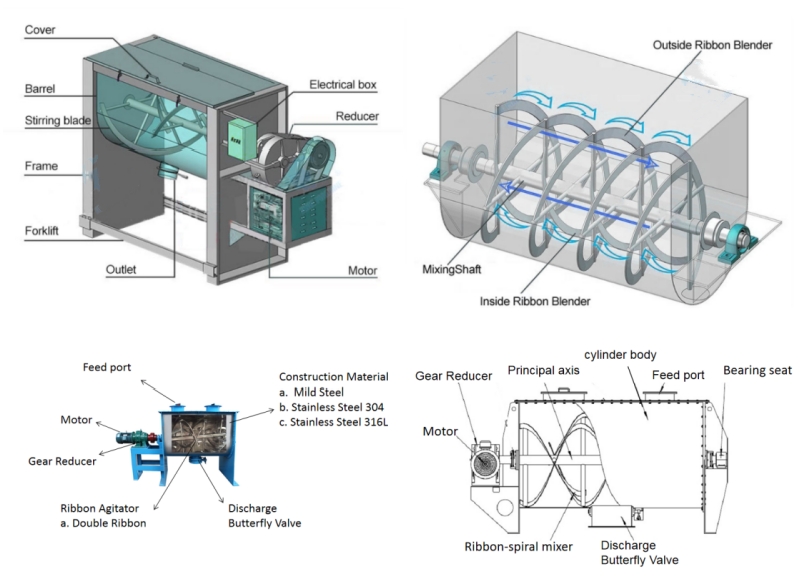

The main components of a dry powder mixer include a mixing container, agitator, transmission and control system. A mixing vessel is usually a cylindrical or conical container of appropriate size and shape to contain the required mixing materials. The stirrer is located inside the mixing container and is used to stir and mix the mixed materials.

Adding materials: First, add the dry powder materials to be mixed into the mixing container. Materials can be added manually or automatically.

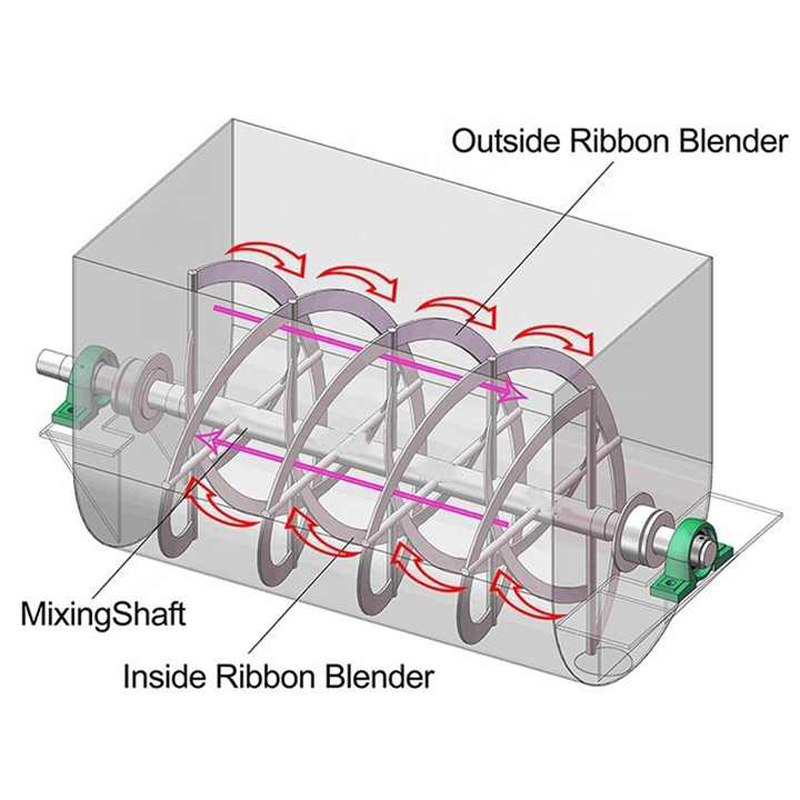

Mixing action: Once the materials are added to the mixing vessel, the mixer begins to rotate or flip to create a mixing action. A stirrer usually consists of a stirring blade or a stirring arm, which pushes and stirs the materials through rotation or flipping motion to achieve mixing of the materials.

Mixing time and speed control: During the mixing process, the mixing time and speed can be adjusted through the control system. According to the nature and requirements of the mixed materials, the appropriate mixing time and stirring speed can be set to ensure that the materials are fully mixed and evenly distributed.

End of mixing and discharge: When the mixing time reaches the set value, the mixing process ends. At this time, the discharge port of the mixing container can be opened to discharge the mixed materials. Unloading can be by gravity flow or auxiliary devices such as unloading valves.

In the working process of dry powder mixer, the movement of the mixer plays a key role. The rotation or flipping motion of the mixer causes the dry powder materials with different components to move relative to each other, thereby achieving mixing of the materials. The shape and structural design of the mixer also have an impact on the mixing effect. Various forms of mixers are usually used, such as spiral, blade, paddle, etc., to meet different materials and mixing requirements.

In addition, dry powder mixers can also be equipped with other auxiliary equipment, such as heating devices, cooling devices, spray devices, etc., to meet special process requirements or improve the mixing effect.

To sum up, the working principle of a dry powder mixer is to push and stir dry powder materials with different components through the rotation or flipping motion of the mixer, thereby achieving uniform mixing of the materials. Mixing time and speed can be adjusted through the control system to meet different materials and mixing requirements. The working principle of the dry powder mixer is simple and intuitive, and can effectively improve mixing efficiency and product quality.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.