Dry powder mixing customer site price will vary based on several factors. The following are some main factors that may affect the price. Since the price will be affected by a variety of factors, the following suggestions are for reference only. The specific dry powder mixing customer on-site price needs to be determined according to your specific needs and geographical location.

Different types of dry powders and specific formulation requirements may have an impact on price. Certain dry powders may require more complex mixing processes and special formulation adjustments, thereby increasing cost and price.

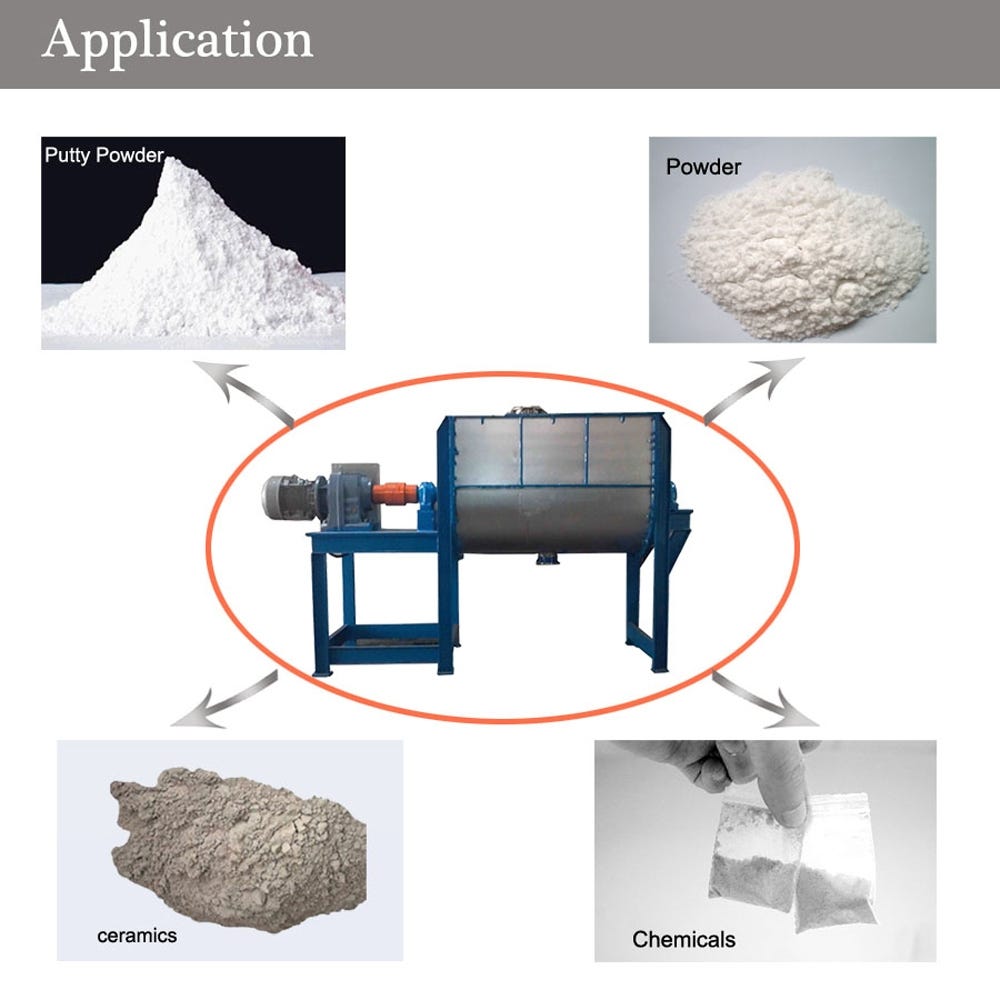

The size and quality level of the mixing equipment will have an impact on the price. Large equipment usually has high production capacity, but its cost is also relatively high. At the same time, if customers have higher quality requirements, they may need to use more sophisticated equipment and processes, thus increasing costs and prices.

Mixing sites may be billed based on mixing time and workload, as this directly affects the use of equipment and human resources. Longer mixing times and extensive work may increase the price.

The price of dry powder raw materials will vary depending on market supply and demand and raw material quality. The mixing site will usually take the cost of the raw materials into account and factor this into the final price.

If the mixing site provides transportation of dry powder, transportation costs may be included in the overall price. Shipping costs typically vary based on factors such as distance, traffic conditions, and mode of transportation.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.