Dry mortar customer site price is affected by many factors. The following are five main factors. These factors are intertwined and have a comprehensive impact on the customer site price of dry mortar. Therefore, the exact price needs to be determined based on the specific situation and customer requirements. It is recommended that you contact your local dry mix mortar supplier or contractor to obtain a detailed quotation and price description.

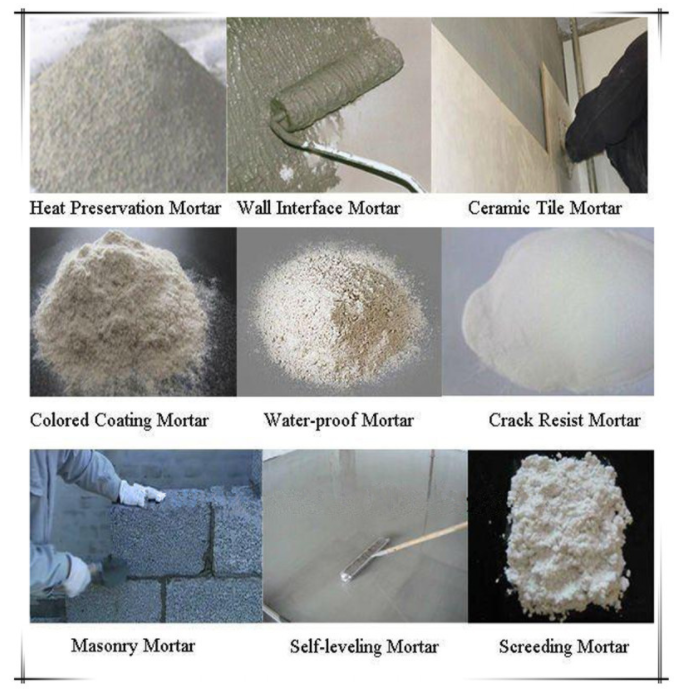

Different types of dry mortar and specific quality requirements will affect the price. For example, special-purpose mortars (such as refractory mortars or cement-based mortars) may require higher-cost raw materials and preparation processes, and therefore have a higher price. At the same time, if the customer has higher quality requirements for the mortar, such as higher strength or durability, a more refined formula and process may be required, increasing the cost and price.

The price of dry mortar at the customer site is usually directly proportional to the scale of the project and the amount of work. Larger projects require more materials and labor, so prices are relatively higher. In addition, the complexity of the project and construction time will also affect the price, as they are directly related to the use of resources and the amount of work.

The price of dry mortar is affected by the cost and supply of raw materials. Fluctuations in raw material prices, scarcity, or supply chain disruptions may lead to higher costs, thereby affecting the price of dry mortar. In addition, the supply of raw materials in different regions may also lead to price differences.

If customers have higher technical requirements for dry mortar, such as special ingredient ratios, precise mixing processes or automated equipment, this will usually lead to an increase in equipment investment and technology costs, thus affecting the price. The use of high-end technology and equipment usually improves the quality and production efficiency of mortar, but also increases the price.

Market competition in different geographical locations will also have an impact on the price of dry mortar. Prices may be higher in areas with relatively few suppliers or higher market demand. And in a competitive market, suppliers may lower prices to attract customers.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.