In industrial production, ribbon mixer is a common mixing equipment used to evenly mix a variety of granular, powdered or liquid materials. Horizontal ribbon mixer and vertical ribbon mixer are two common types, each with specific structures and advantages, which can ensure the uniformity and stability of the mixed materials. Choosing the right type of ribbon mixer depends on the specific properties of the mixed materials, mixing requirements and production scenarios to meet the efficient demand for material mixing in industrial production.

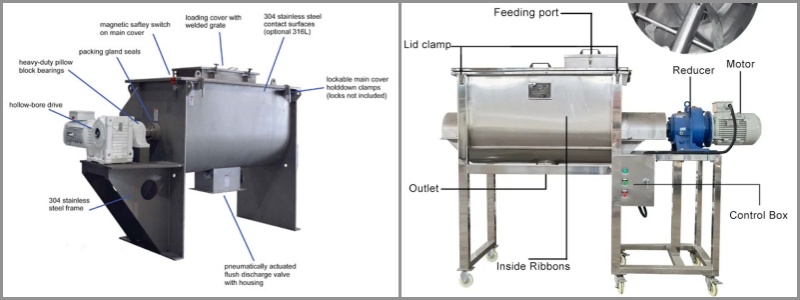

Horizontal ribbon mixer:

Horizontal arrangement: The ribbon agitator of the horizontal ribbon mixer is arranged horizontally inside the container, and the materials are mixed in the horizontal direction.

Double ribbon design: Most horizontal ribbon mixers have a double ribbon design to improve the mixing effect.

Compact overall structure: The overall structure of the equipment is compact, the footprint is small, and it is suitable for installation in limited space.

Vertical ribbon mixer:

Vertical arrangement: The ribbon agitator of the vertical ribbon mixer is arranged vertically inside the container, and the materials are mixed in the vertical direction.

Single-ribbon design: Most vertical ribbon mixers adopt a single-ribbon design, which is suitable for some specific mixing needs.

Small footprint: The equipment has a compact structure and a small footprint, which is suitable for use in small factories or laboratories.

Horizontal ribbon mixer:

Uniform mixing: The ribbon agitator design allows the materials to be fully turned and mixed during the mixing process to ensure uniform mixing.

Wide applicability: It is suitable for mixing granular, powdery and viscous materials, covering a variety of industrial applications.

Easy operation: It is simple to operate, easy to clean and maintain, and improves production efficiency.

Vertical ribbon mixer:

Efficient mixing: The ribbon agitator design allows the materials to be mixed quickly in the vertical direction, and the mixing effect is better.

Space saving: The equipment has a compact structure and is suitable for production sites with limited space.

Suitable for specific needs: It is suitable for certain specific mixing needs, such as situations where the mixing time is required to be short.

Horizontal ribbon mixer:

Chemical industry: It is used for mixing granular and powdery materials, such as chemicals, pigments, etc.

Food industry: used for mixing food raw materials, such as flour, seasonings, etc.

Pharmaceutical industry: used for mixing pharmaceutical raw materials to ensure the quality and stability of pharmaceuticals.

Vertical ribbon mixer:

Building materials industry: used for mixing building materials such as cement and lime.

Metallurgical industry: used for mixing materials such as metal powder and ore.

Environmental protection industry: used in solid waste treatment, waste material recycling and other fields.

Both horizontal ribbon mixers and vertical ribbon mixers play an important role in industrial production, and each is suitable for different mixing needs and scenarios. Choosing the right type of ribbon mixer depends on the specific properties of the mixed materials, mixing requirements and production scenarios to ensure the efficiency of the production process and the stability of product quality.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.