Can mix feed pellets, grains, protein sources, vitamins and minerals, additives and other auxiliary raw material,separating products into 2-5 different sizes

![]()

![]()

Price:$300.00-$3,500.00/Set

Consult now and enjoy a 10% discount

Capacity: Up to 1000 Liter

Phase: Three Phase

Frequency (Hz): 50 Hz

Voltage: 380 Volt

Each mixing amount: 100-6000 (kg)

Mixing time: 1-10min

Power: 13.5-75kw

Feeding method: manual feeding, automatic feeding or other methods

Discharging method: manual unloading, automatic unloading or other methods

Weight: 100kg-7500kg

Application: It is suitable for feed pellets, grains (such as corn, soybeans, wheat), protein sources (such as fish meal, meat and bone meal, soybean meal), vitamins and minerals (such as fish oil, salt, phosphate), additives (such as yeast, Amino acids, enzyme preparations) and other auxiliary raw materials (such as forage, wheat bran, fish feed).

Commitment: Free Shipping/5 Days Delivery/30-Day Returns/Support Customization

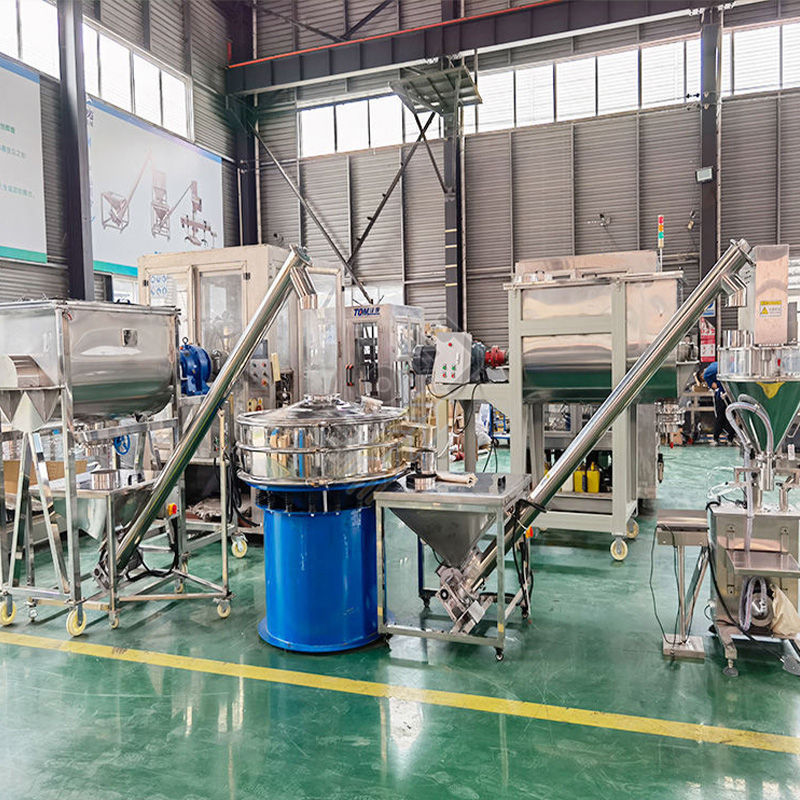

Household feed mixer is a piece of equipment specially used in households or small-scale farms to mix different types and proportions of feed ingredients to prepare a uniform feed formula. It usually consists of a container and mixing device. The household feed mixer has the characteristics of simple structure, convenient operation and good mixing effect.

Household feed mixers are suitable for poultry breeding, livestock breeding, farms, feed processing plants and other scenarios. They provide farmers with convenient and fast feed preparation tools to help improve feed quality and breeding efficiency. In addition, through mixing, the stability and preservation of the feed can be improved, the dust and waste of the feed can be reduced, and the utilization rate of the feed can be improved.

Household feed mixers have a wide range of application scenarios in the breeding industry. It is suitable for family breeding, small-scale breeding farms, and farmers in rural areas.

Detailed introduction to specific application scenarios and mixed materials:

Poultry breeding: Household feed mixer can be used to mix poultry feed, such as chicken feed, duck feed, goose feed, etc. Mixed materials include grains (such as corn, wheat), protein sources (such as soybean meal, fish meal), vitamins and minerals, additives, etc. With the mixer, a uniform feed formula can be prepared to meet the nutritional needs of poultry.

Livestock breeding: Household feed mixers are also suitable for mixing livestock feed, such as pig feed, cattle feed, sheep feed, etc. Mixed materials include grains (such as corn, soybeans), protein sources (such as soybean meal, meat and bone meal), vitamins and minerals, additives, etc. Through the mixer, a uniform feed formula can be prepared to improve the growth rate and health of livestock animals.

Farms and feed processing plants: In large-scale farms and feed processing plants, household feed mixers can be used to mix various feed ingredients, including grains, protein sources, vitamins and minerals, additives, etc. It can improve the stability and uniformity of feed, ensure the consistency of feed formula, and meet the needs of large-scale breeding.

The working principle of the household feed mixer is to uniformly mix different types and proportions of feed ingredients through the mixing device. The feed raw materials are first added into the mixer through the feed port, and then the mixing device starts to rotate or move up and down to fully contact and mix the feed raw materials. The mixing device usually consists of mixing blades or propellers, which can quickly stir and turn the feed ingredients to evenly distribute them. During the mixing process, vitamins, minerals and other additives can also be added as needed. Finally, the mixed feed particles are discharged through the discharge port to achieve the purpose of improving feed stability, uniformity and nutritional value.

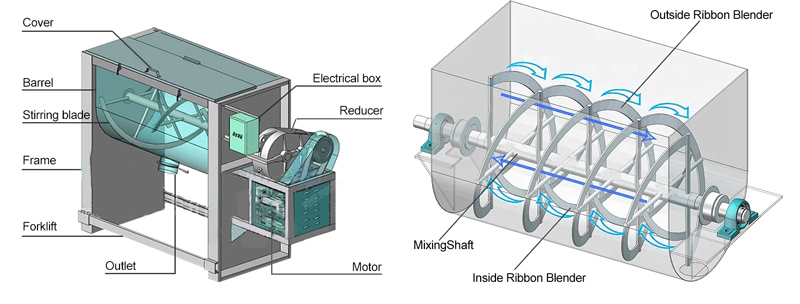

Here's the principle and steps involved in the mixing process of a ribbon mixer:

Loading: The materials to be mixed, such as powders, granules, or pastes, are loaded into the U-shaped trough of the mixer.

Rotation: The horizontal shaft, along with the inner and outer ribbon blades, starts rotating. The ribbon blades are designed to move the materials in a specific manner.

Shearing Action: As the ribbon blades rotate, they create a shearing action by moving the materials in opposite directions. The inner ribbon blade pushes the material in one direction, while the outer ribbon blade pushes it in the opposite direction. This shearing action helps break up clumps, agglomerates, or any cohesive particles present in the mixture.

Folding Action: The twisted design of the ribbon blades also causes a folding action as they move through the material. This folding action helps to further blend and homogenize the components, ensuring thorough mixing.

Circulation: The rotation of the ribbon blades also causes the materials to circulate within the mixing trough. This circulation helps to expose different parts of the mixture to the shearing and folding actions, promoting uniform mixing.

Discharge: Once the desired mixing time is achieved, the mixed material is discharged from the mixer through an outlet, typically located at the bottom of the trough.

Usually each batch of materials is mixed in 1-10 minutes to achieve full mixing and stirring, and 500-4000kg feed powder 3-6 minutes, which is 6-10 times more efficient than other mixers.

304 stainless steel is used for material contact parts, with good finish, convenient operation and maintenance, and meets food-grade hygiene requirements.

The optimally designed two-way spiral-belt rotor has mild mixing process, high uniformity and no segregation.

Applicable to a wide range of materials, including grains, protein sources, vitamins and minerals, additives, etc.

It can be equipped with multiple spray atomizers to add various liquids.

Household feed mixers allow for personalized customization of feed formulas based on the special needs of

| Model | LHY-0.25 | LHY-0.5 | LHY-1 | LHY-1.5 | LHY-2 | LHY-3 | LHY-4 | LHY-6 | LHY-8 | LHY-10 |

| One-time mixing (kg) | 100-150 | 200-300 | 400-600 | 600-900 | 800-1000 | 1200-1800 | 1600-2400 | 2400-3600 | 3200-4800 | 4000-6000 |

| Mixing time (min) | 8-20 | 8-20 | 8-20 | 8-20 | 8-20 | 8-20 | 8-20 | 8-20 | 8-20 | 8-20 |

| Mixing speed (r/min) | 60 | 55 | 45 | 40 | 35 | 25 | 25 | 20 | 15 | 15 |

| Motor power (kw) | 3-5.5 | 4-11 | 7.5-15 | 11-18.5 | 15-22 | 18.5-30 | 22-37 | 37-55 | 37-55 | 45-75 |

| Weight (kg) | 500 | 900 | 1800 | 2500 | 3200 | 4100 | 5100 | 6300 | 7500 |

Materials: Materials can be carbon steel, manganese steel, ss304, 316L and 321; in addition, different materials can be used in combination. Stainless steel surface treatment including sandblasting, wire drawing, polishing, mirror polishing, can be used for different parts of the mixer

Motor options: general motor, explosion-proof motor, variable frequency motor, high-efficiency and energy-saving motor. Commonly used reducers: R series, K series, F series gearboxes; cycloid reducer, universal gear reducer, planetary gear reducer. Common motor-gearbox connection methods: direct connection, pulley connection, fluid coupling connection.

Feeding port: Various air inlets on the top cover of the bucket can be designed according to different situations and can be used as manholes, sweeping doors, feeding holes, exhaust holes and dust collecting holes. The top cover can be designed as a fully open cover for easy cleaning.

Discharge port: The drive types of valve are Manual, pneumatic, and electric.

Valves for consideration: powder spherical valve, cylinder valve, plum-blossom dislocation valve, butterfly valve, rotary valve etc.

Mixing unit: Different main shaft agitators can be equipped according to the properties of raw materials.

The main shaft agitator could be: inner and outer ribbon, paddle and ribbon, disconnected ribbon, and shaver-shaped agitator.

Mr. Li is a farmer who raises a number of poultry and rabbits at home. Since the types of feed on the market were limited and prices were high, he decided to buy a home feed mixer to mix the feed himself. Mr. Li chose a feed mixer suitable for home use and customized the capacity of the mixing barrel and the specifications of the mixer according to his own needs.

Through the household feed mixer, Mr. Li can mix different types of feed ingredients according to the nutritional needs of poultry and rabbits to provide balanced and nutritious feed to the animals. He found that after using the household feed mixer, the growth and health of the animals were significantly improved. In addition, Mr. Li is able to save a certain amount of feed costs by mixing his own feed.

Xinxiang Dahan household feed mixer manufacturer is located in Xinxiang City, Henan Province, China. As a professional feed machinery manufacturer, committed to developing, producing and selling high-quality household feed mixers. The factory has advanced production equipment and technical team, focusing on product quality and innovation. The household feed mixer uses high-quality materials and advanced manufacturing processes to ensure product stability and durability. Xinxiang Dahan Factory's household feed mixers are available in a variety of models and specifications to meet the needs of different users. The product has reasonable design, simple operation and good mixing effect, and is well received by users. In addition to product quality and performance, Xinxiang Dahan household feed mixer manufacturer also focuses on after-sales service, providing professional pre-sales consultation and after-sales technical support.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.