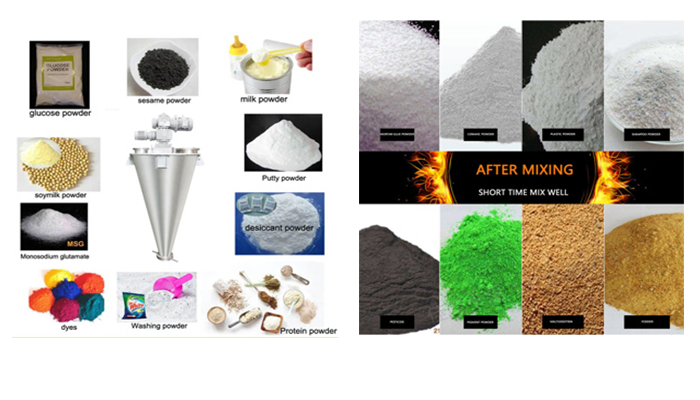

Used to mix powdery and granular materials with high mixing effect and even distribution of ingredients.

![]()

![]()

Price:$300.00-$3,500.00/Set

Consult now and enjoy a 10% discount

Revolution speed: 2r/min

Feed size: 20-450 mesh

Material: Stainless Steel 304 / SUS316L

Capacity: 400-12000kg

Application: Capsule granules, Chinese medicine condiments, powdered or granular Chinese herbal medicines, iron powder, copper powder, magnesium powder and other chemical powders, fishing feed, poultry feed, wildlife feed, bird feed, condiments, additives, vitamins, various sugar products, cement, limestone powder, coal powder, ore powder, etc.

Commitment: Free Shipping/5 Days Delivery/30-Day Returns/Support Customization

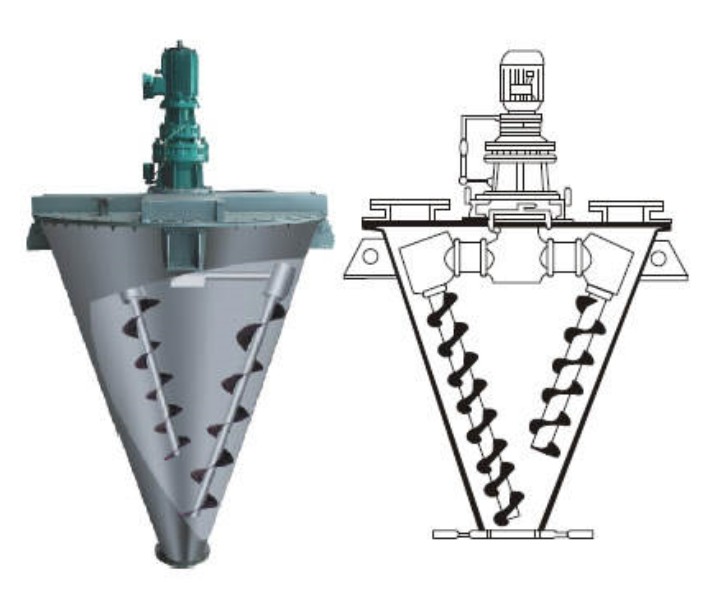

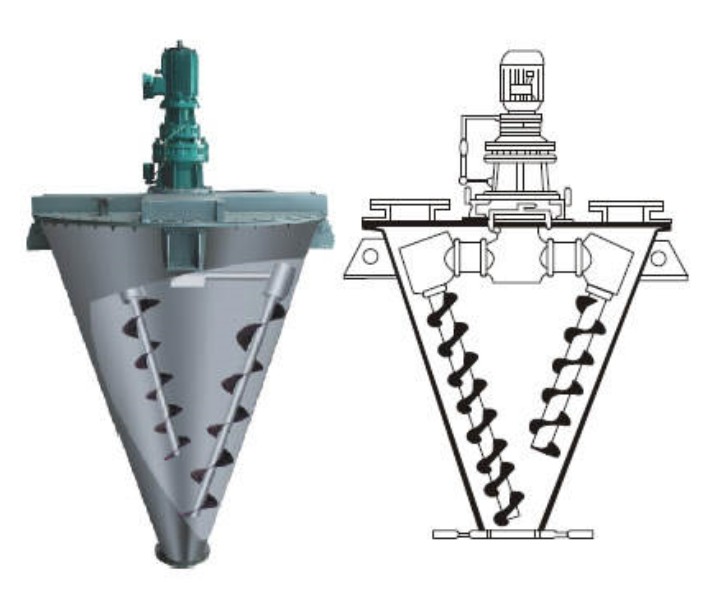

Single cone double screw mixer is a new type of mixing equipment, which consists of a conical container and two mutually spiral twin-screws. The rod rotates along the axis of the container, conveying material from one end of the container to the other, while pushing material downward from the top.

The machine has strong adaptability to mixtures and will not cause overheating of heat-sensitive materials; it will not press or grind granular materials; mixtures composed of materials with different specific gravity and different particle sizes will not stratify or dissociate; it will not delaminate or dissociate for coarse powders. It also has good adaptability to the mixing of various granular, fibrous or flaky materials such as , fine powder and ultra-fine powder. It is widely used in pharmaceutical, chemical, food, agriculture and other industries to mix various materials and improve product quality and stability.

Single cone double screw mixers are widely used in many industries and fields, mainly including the following aspects:

Chemical industry: used for mixing pigments, dyes, plastic powder, rubber powder and other chemical raw materials to achieve uniform mixing and stability.

Pharmaceutical industry: Suitable for mixing pharmaceutical raw materials such as pharmaceutical powders, herbal powders, preparation raw materials, etc. to ensure uniform distribution and consistency of drugs.

Food industry: used to mix food additives, seasonings, flour, starch and other food raw materials to improve the uniformity and taste of the product.

Agricultural breeding: It can be used to mix pesticide particles, feed additives, fertilizer particles and other agricultural raw materials to improve feed quality and fertilization effect.

Mining industry: suitable for mixing cement, limestone powder, coal powder, ore powder and other mineral powders to improve the uniformity and reaction efficiency of the ore.

Construction engineering: 6.In the construction industry, single cone double screw mixers can be used to mix dry mortar powder materials to improve construction efficiency and mortar quality.

In general, single cone double screw mixers are suitable for various industrial and production fields that require uniform mixing of powdery and granular materials to improve product quality, stability and production efficiency.

Single cone double screw mixer uses the double-helix mixing spiral inside the mixing barrel to mix the materials by using the rotation and pushing action of the spiral. After the material enters the mixing barrel through the feed port, the rotation of the screw causes the material to flow rapidly in the mixing barrel while shearing, folding and exchanging at the same time to achieve uniform mixing. The cross action of clockwise screw and counterclockwise screw makes the material fully mixed. After mixing is completed, the mixed material is discharged through the discharge port.

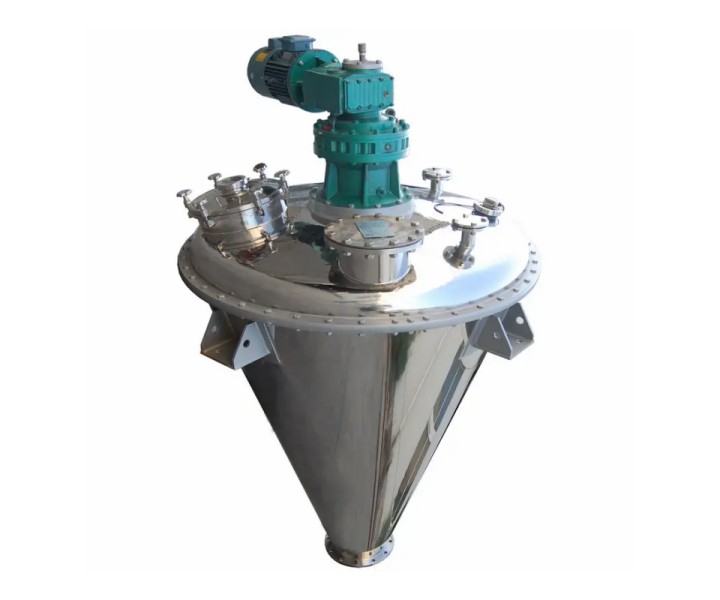

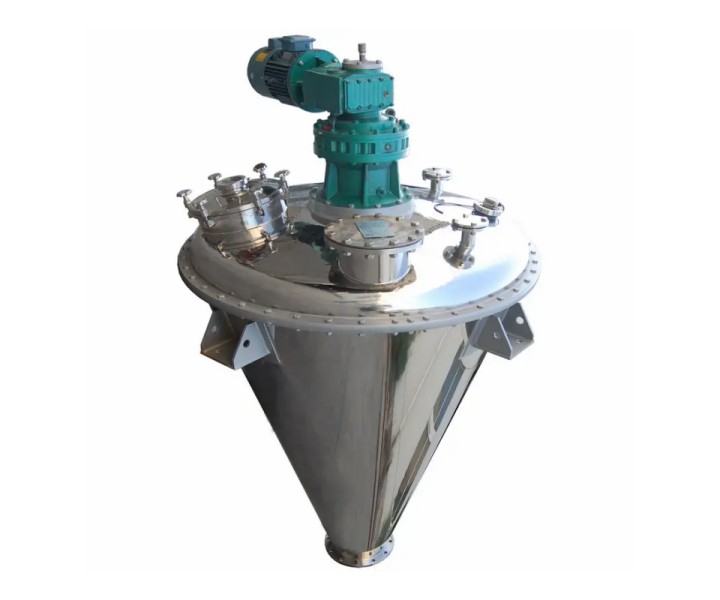

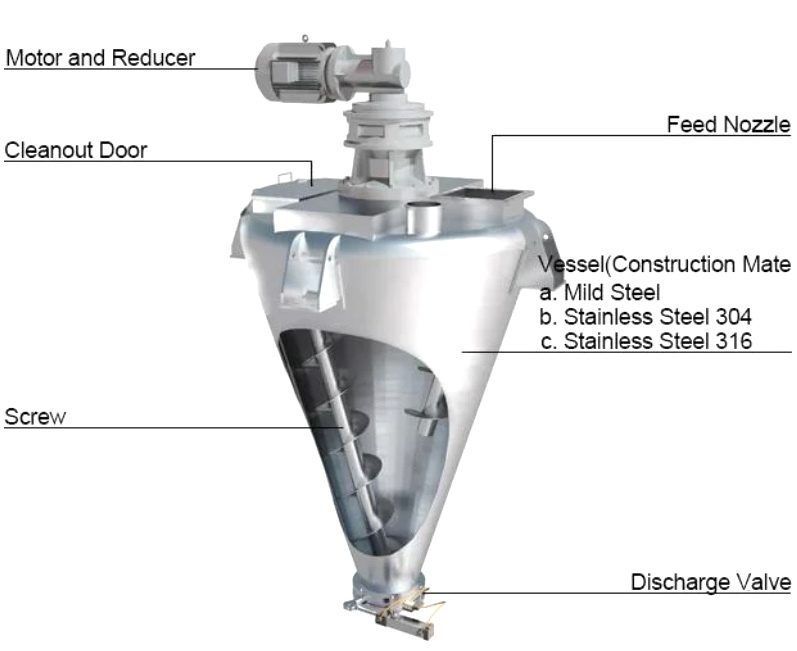

Single cone double screw mixer is a common mixing equipment, which mainly consists of the following parts:

Mixing barrel: The mixing barrel is the main component of the single cone and double screw mixer and is usually conical in design.

Double helix: There are two mixing spirals inside the mixing barrel that spiral into each other. These two spirals are arranged spirally along the wall of the mixing barrel, one is a clockwise spiral and the other is a counterclockwise spiral.

Transmission device: The transmission device usually consists of a motor, a reducer, a coupling, etc., and makes the spiral rotate by transmitting power and torque.

Feed port and discharge port: The mixing barrel is equipped with a feed port and a discharge port. Materials enter the mixing cylinder through the feed port. After mixing is completed, the mixed materials are discharged through the discharge port.

Support structure: The support structure consists of base, support feet and support frame.

Easy operation and maintenance

Single cone double screw mixer has advanced structure, easy operation, safe and reliable operation.

Good mixing effect

The mixing speed is fast and the quality is uniform. The machine's double screw asymmetric arrangement is more suitable for mixing materials with different specific gravity and different mixing ratios.

Save energy consumption

The energy saving effect is remarkable. Compared with the drum mixer, the energy consumption of this machine is only one-tenth of that.

Strong adaptability

The wear and pressure of granular materials is small, and no overheating reaction will occur in the mixing of heat-sensitive materials.

Mixing is more stable

The mixed preparation is stable without stratification or segregation.

long lasting

The single cone double screw mixer is sealed and dust-free, easy to operate, easy to maintain and has a long service life.

| Model | Total volume(L) | Capacity(kg) | Mixing time(Minutes) | Power(kw) | Total height(m) | Weight(kg) | |

| CF-DSH-1 | 1000 | 400-600 | 5-10 | 4 | 2775 | 1200 | |

| CF-DSH-2 | 2000 | 800-1200 | 5-10 | 5.5 | 3424 | 1500 | |

| CF-DSH-6 | 6000 | 2400-3600 | 5-10 | 15 | 4960 | 3500 | |

| CF-DSH-8 | 8000 | 3200-4800 | 5-10 | 18.5 | 5378 | 4000 | |

| CF-DSH-10 | 10000 | 4000-6000 | 5-10 | 18.5 | 5678 | 4300 | |

| CF-DSH-12 | 12000 | 4800-7200 | 5-10 | 22 | 6015 | 4500 | |

| CF-DSH-15 | 15000 | 6000-9000 | 5-10 | 30 | 6650 | 5000 | |

| CF-DSH-20 | 20000 | 8000-12000 | 5-10 | 37 | 7176 | 6000 |

Single cone double screw mixer can often be customized according to customer needs to suit different applications and process requirements. Here are some possible ribbon mixer customization options:

Single cone double screw mixer VS Single cone single screw mixer: A single cone double screw mixer is a mixing device with two screws.This design provides higher mixing efficiency and uniformity. The single cone double screw mixer is suitable for mixing various powdery and granular materials.Single cone single screw mixer is a mixing device with a single screw, usually located in a conical container. It is suitable for some materials that do not require high mixing effect. It is commonly used in laboratories, small batch production and some special process applications.

material selection: Material can be stainless steel, 304, 316; different material can also be used in parts, between the part contact with the raw material and the parts don't contact with the raw material. Surface treatment for stainless steel can be sandblasting, wiredrawing, polishing, mirror polishing.

driven unit: The driven unit and power is varied according to different raw material, starting method, and processing.Double screw conical mixer is equipped with appropriative double output reducer, which combines pinwheel, gear and warm and gear.

discharging unit: Spherical valve or plum-blossom dislocation valve is matched to the double screw conical mixer.The surface of the valve match the track of the bottom of screw, to reduce the mixing dead zone to the maximum, and to make the largest discharging area, so as to make sure no leftover. Spherical valve has excellent sealing effect to powder, liquid and even in the negative pressure state.Plum-blossom dislocation valve is easy to operate and control the discharging speed.

A pharmaceutical company uses a single cone double screw mixer in production to mix pharmaceutical raw materials and excipients. This equipment helps them achieve precise mixing of pharmaceutical formulas, ensuring product quality and stability. By optimizing the mixing process, they succeeded in increasing production efficiency, reducing production costs, and ensuring uniformity and consistency of the drug product. Customers appreciate the mixer's reliability and performance, citing the equipment as playing a key role in their production processes.

Xinxiang Dahan Factory is a manufacturer specializing in the production and manufacturing of single cone double screw mixers. The manufacturer has rich experience and a professional technical team in the design, manufacture and sales of single cone double screw mixers. The manufacturer pays attention to product quality and technological innovation, and the single cone double screw mixers produced are made of high-quality materials. Manufacturers provide mixers of various specifications and models to meet customers' different production requirements. Xinxiang Dahan Factory also provides pre-sales consultation, in-sales technical support and after-sales services, and can provide customized solutions according to customer needs.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.